Synthetic resin pallet

A synthetic resin and pallet technology, applied in rigid containers, containers, packaging, etc., can solve the problems of cargo collapse, damage, limit the number of synthetic resin pallets arranged side by side, etc., achieve reliable propulsion operations, simple handling, and prevent cargo collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

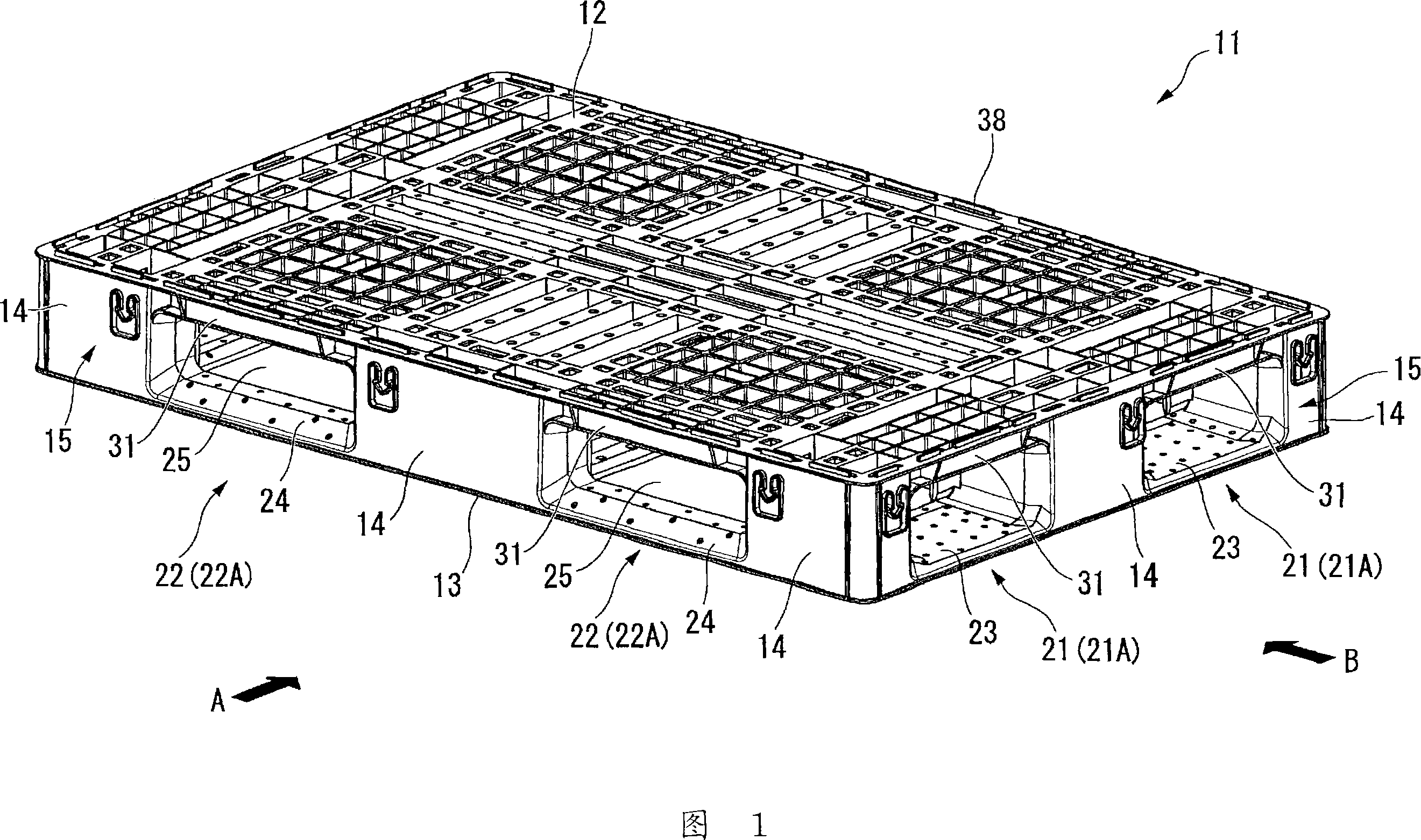

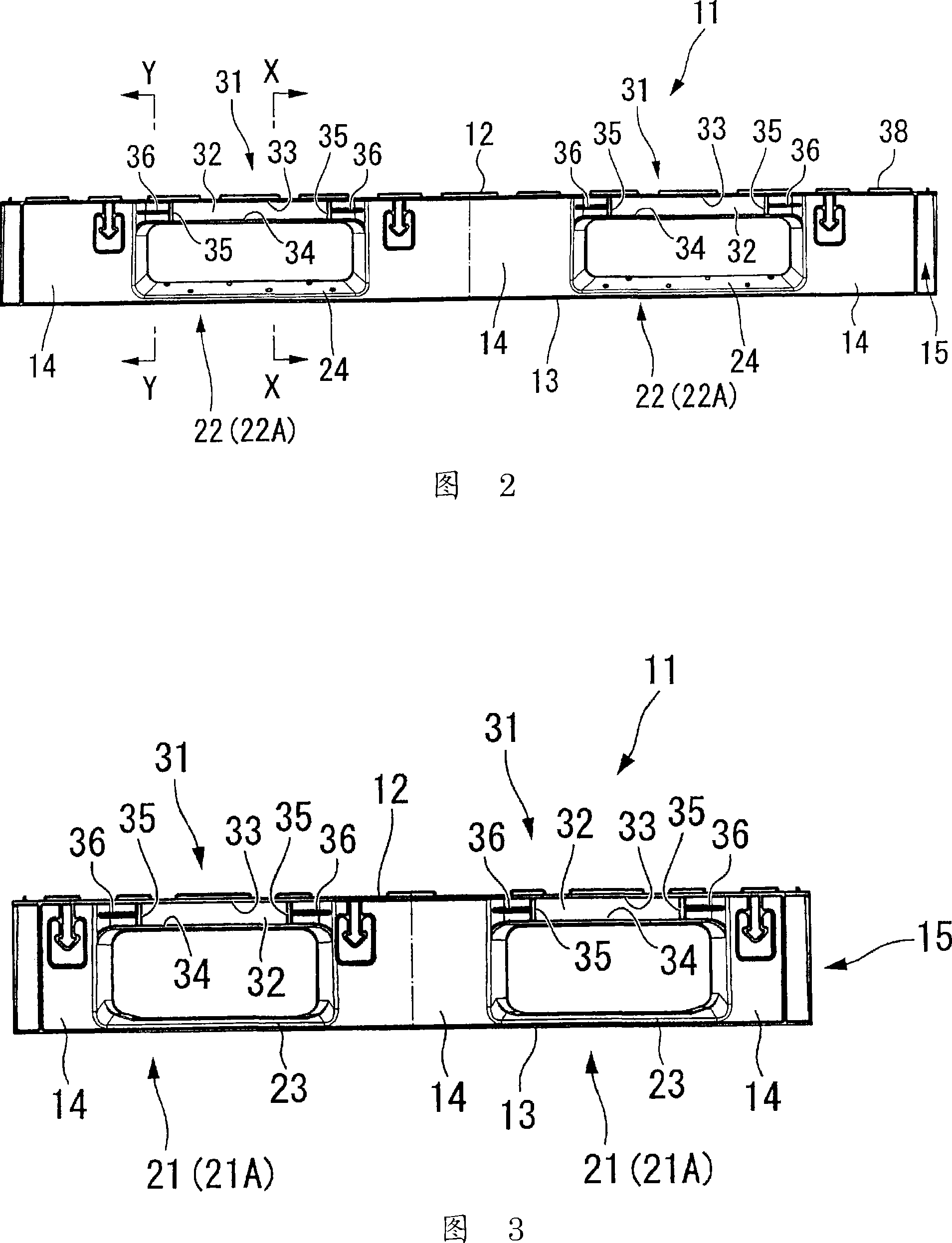

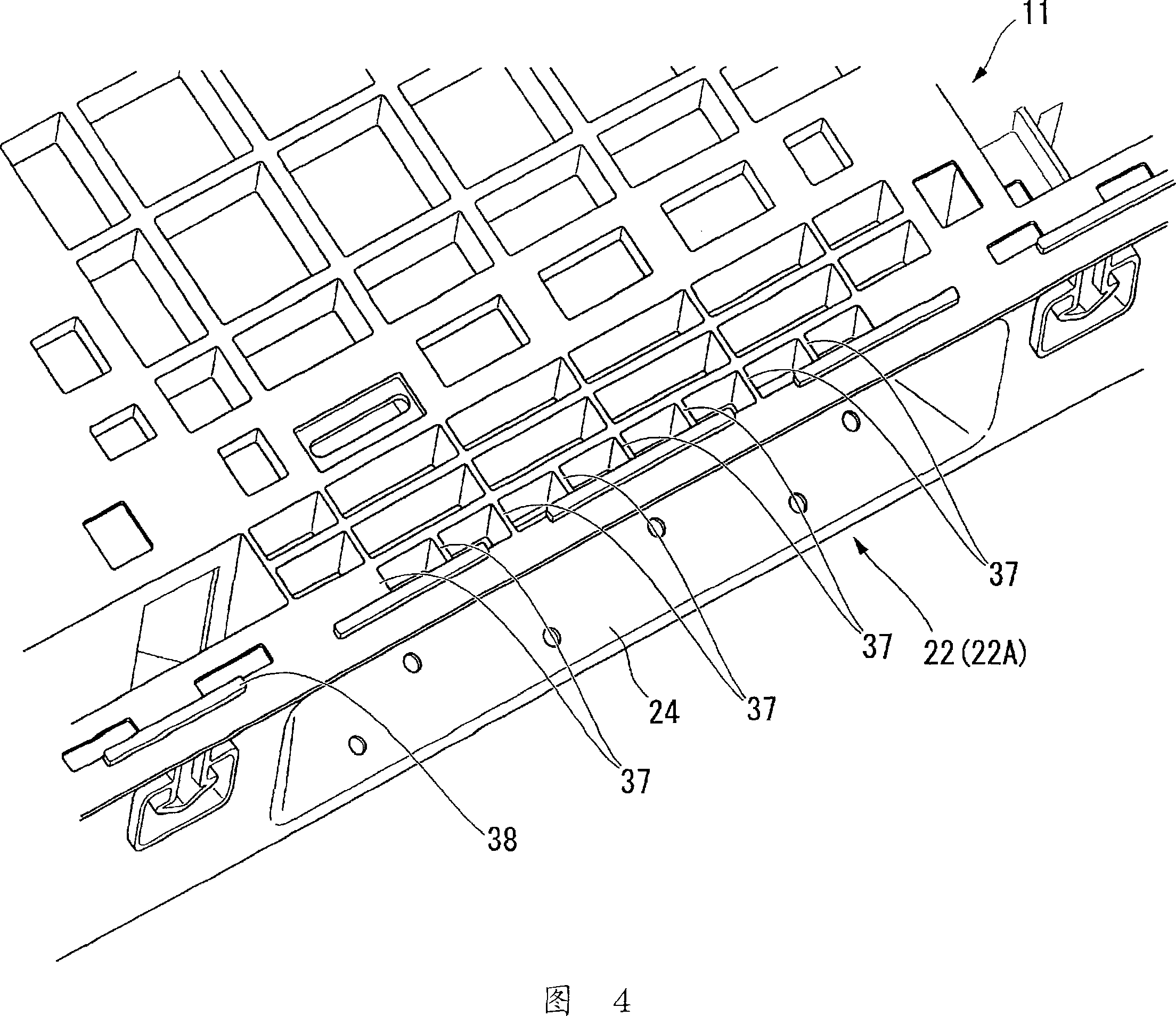

[0040] Hereinafter, a synthetic resin tray according to an embodiment of the present invention will be described with reference to the drawings.

[0041] 1 to 6 show a synthetic resin tray according to an embodiment of the present invention.

[0042] As shown in FIG. 1 , the synthetic resin tray 11 is formed in a rectangular box shape as a whole, and has an upper surface plate portion 12 forming the upper surface of the synthetic resin tray 11 and a lower surface plate forming the lower surface of the synthetic resin tray 11. Shaped portion 13, and beam portion 14 connecting the upper surface plate portion 12 and the lower surface plate portion 13 to each other. As shown in FIGS. 2 and 3 , the upper plate-like portion 12 and the lower plate-like portion 13 are arranged substantially in parallel.

[0043] Two pairs of fork insertion holes 21, 21 or 22, 22 for inserting forks of a forklift or pallet truck are formed between the beams 14 of the synthetic resin pallet 11 having t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com