Typing tip drive agency

A transmission mechanism and print head technology, applied in printing, transfer materials, power transmission devices, etc., can solve the problems of low efficiency and high processing requirements of the base, and achieve the effect of convenient tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

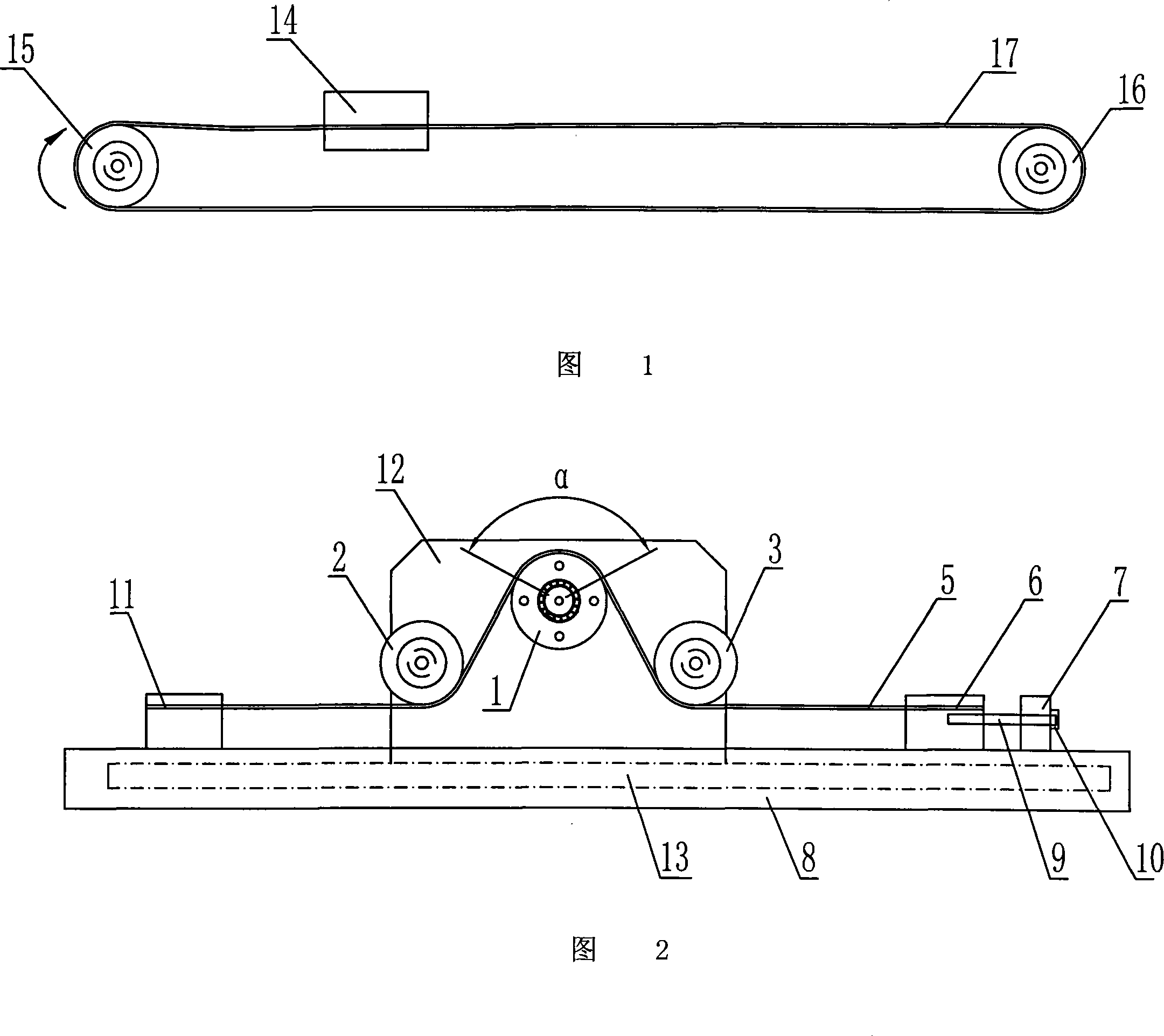

[0016] Referring to Fig. 1, in the prior art, the rotation of the pulley generally drives the spray head or print head to perform linear reciprocating motion. In this structure, the motion platform 14 with the print head installed is fixed on the tight side of the conveyor belt 17, and is driven by the drive motor. The reciprocating motion of the motion platform 14 is realized by driving the forward and reverse rotation of the pulley 15 and the pulley 16 .

[0017] Referring to Fig. 2, the printing head drive mechanism of the present invention comprises frame 8 with guide rail 13 and the moving platform 12 that is fixed with printing head, is provided with driving wheel 1, pinching wheel 2 and pinching wheel 3 on the moving platform 12, synchronously The belt 5 partially covers the driving wheel 1 under the limitation of the pressing wheel 2 and the pressing wheel 3, and the two ends of the synchronous belt 5 are fixed on the frame 8, and the driving wheel 1 drives the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com