Mine underground storage tank can

A mine and oil truck technology, which is applied in the field of oil storage trucks, can solve the problems of time-wasting oil, rough oiling methods, time-consuming and labor-intensive, etc., and achieve the effects of saving time, reducing oil loss, and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

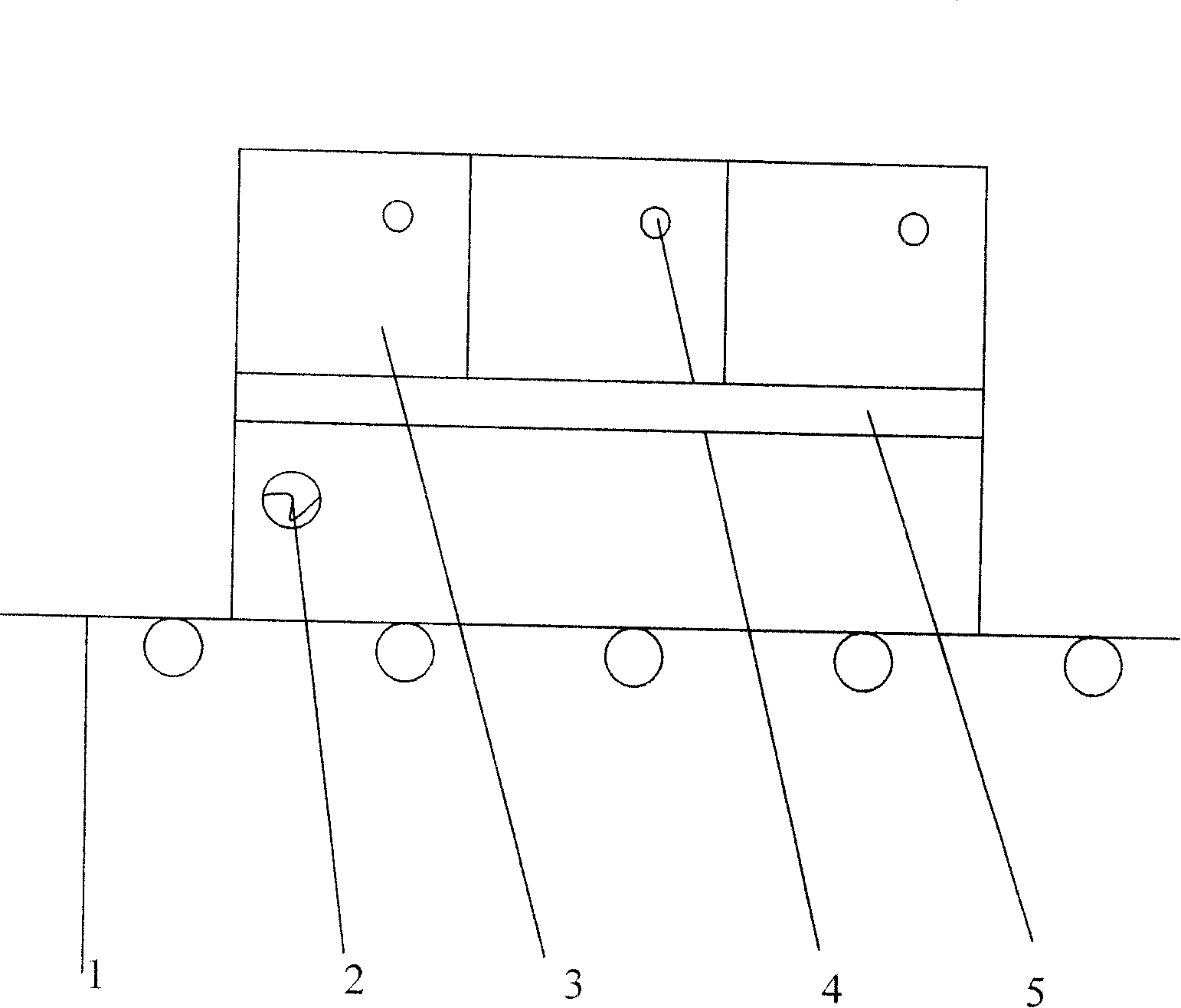

[0012] The oil storage vehicle used in underground mines of the present invention is provided with an oil storage cavity 3 inside the vehicle 1, and a hand pump 2 is arranged outside the oil storage cavity 3, and the oil storage cavity 1 is connected with a rotatable oil nozzle 4.

[0013] A retractable oil receiving box 5 is arranged directly below the rotatable oil nozzle 4 .

[0014] Described oil storage chamber 3 is three chambers.

[0015] The three chambers are respectively filled with gear oil, emulsified oil and anti-wear oil.

[0016] The oil storage car 1 is arranged on the flat mine car 1, and moves forward with the advancement of the working face together with the substation train on the working face.

[0017] When taking oil, shake the handle of the hand pump 2, and the oil will flow into the plastic oil barrel at a constant speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com