Modular switching equipment

A switchgear and modular technology, applied in the direction of electric switches, protection switches, components of protection switches, etc., can solve the problem of not being able to obtain detachable fixation of functional modules, and achieve the effect of simple replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

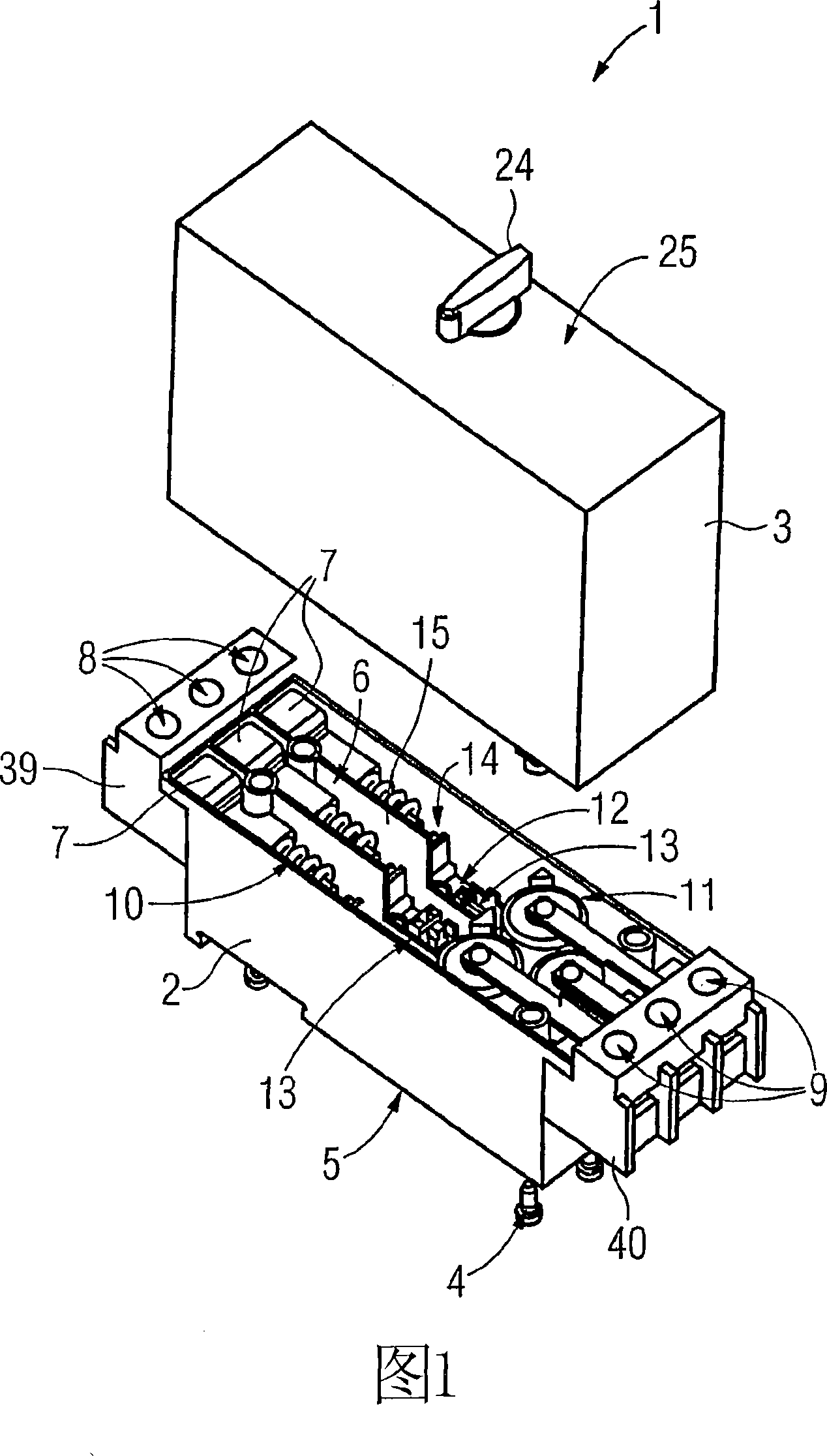

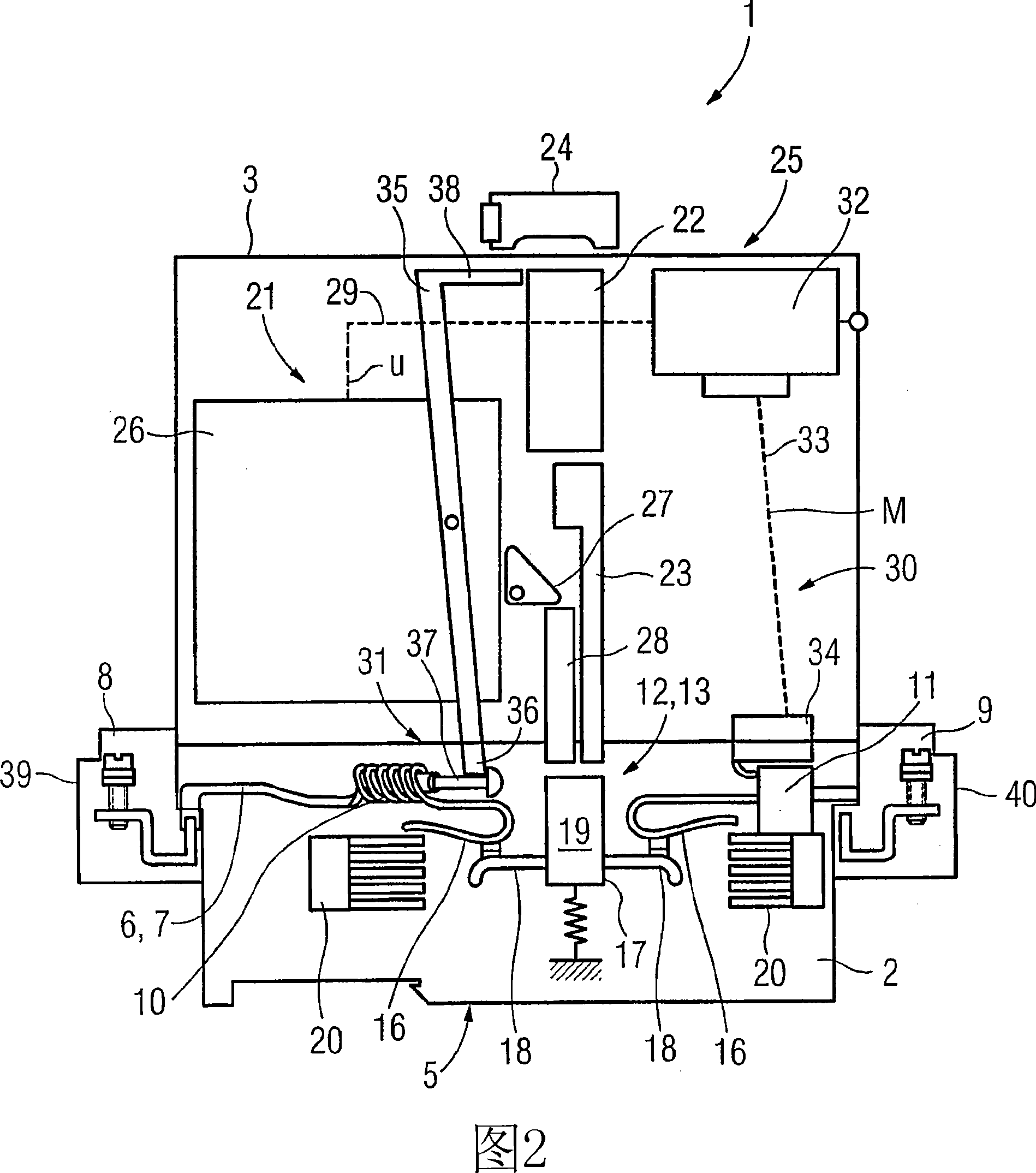

[0018] Like parts and quantities are indicated by like reference symbols in the various figures.

[0019] The switchgear 1 shown in FIG. 1 comprises a switch box 2 and a base module 3 which can be plugged into the switch box. Wherein, the switch box 2 and the basic module 3 can be fixed together by fastening screws 4, and the fastening screws 4 can be operated from the switch box 2 away from the bottom surface 5 of the basic module 3, wherein, when the switch box 2 needs to be replaced, it can be The screw connection is released in a destructive manner, so as to continue to use the basic module 3 after replacing the switch box 2 .

[0020] The switching device 1 is implemented as a three-pole switching device and comprises a main circuit 6 which is divided into three individual lines 7 corresponding to the number of poles. Each single line 7 serves to conduct current between a first connection terminal 8 and a second connection terminal 9 . Inside each individual line 7 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com