Method and device for detaching reclaimed liquid crystal display

A technology of liquid crystal display and cutting device, which is applied to the accessories of shearing machine, shearing device, recycling of electronic waste, etc., can solve the problem that LCD panel is not easy to disassemble quickly, and achieve the effect of saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

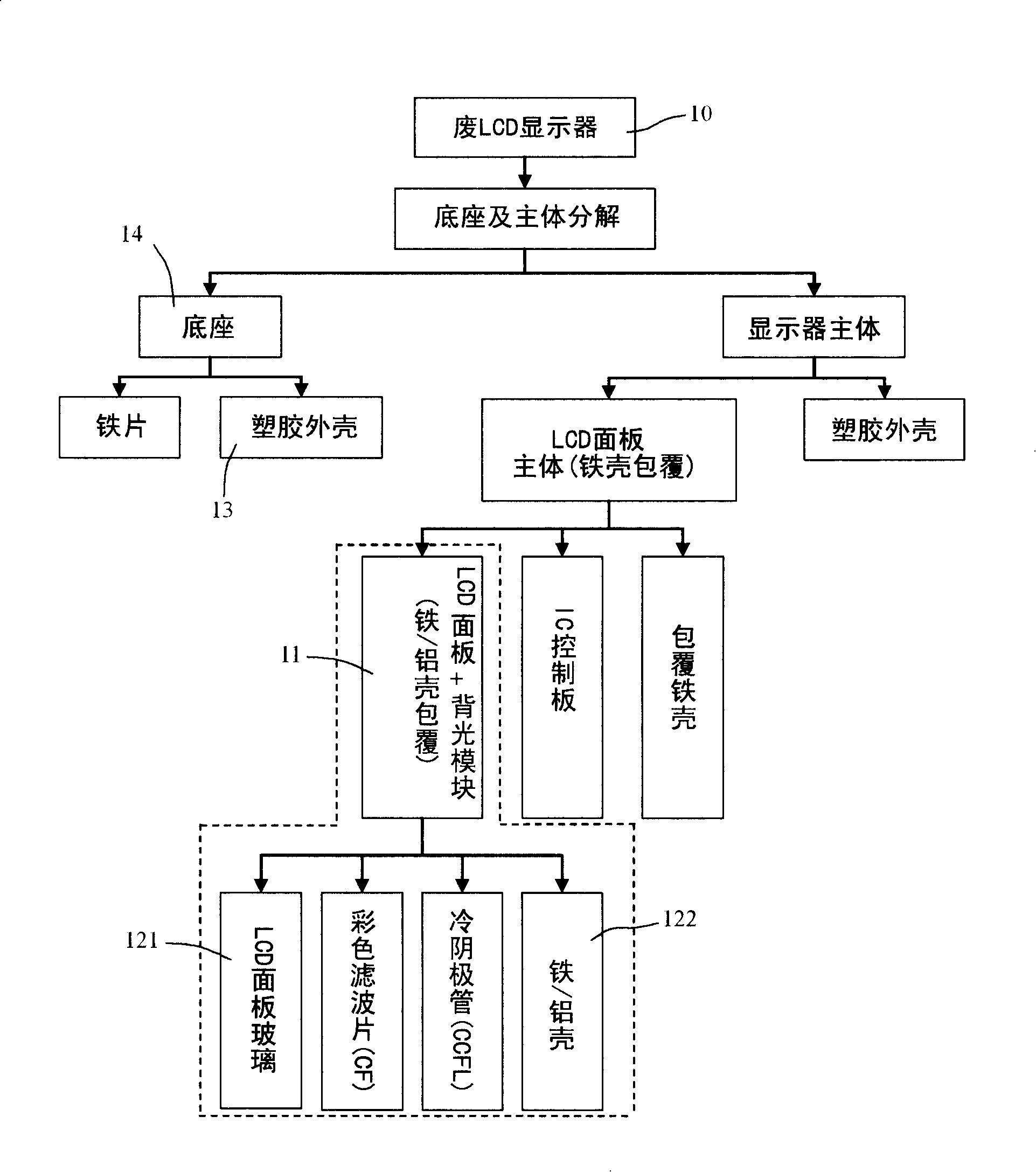

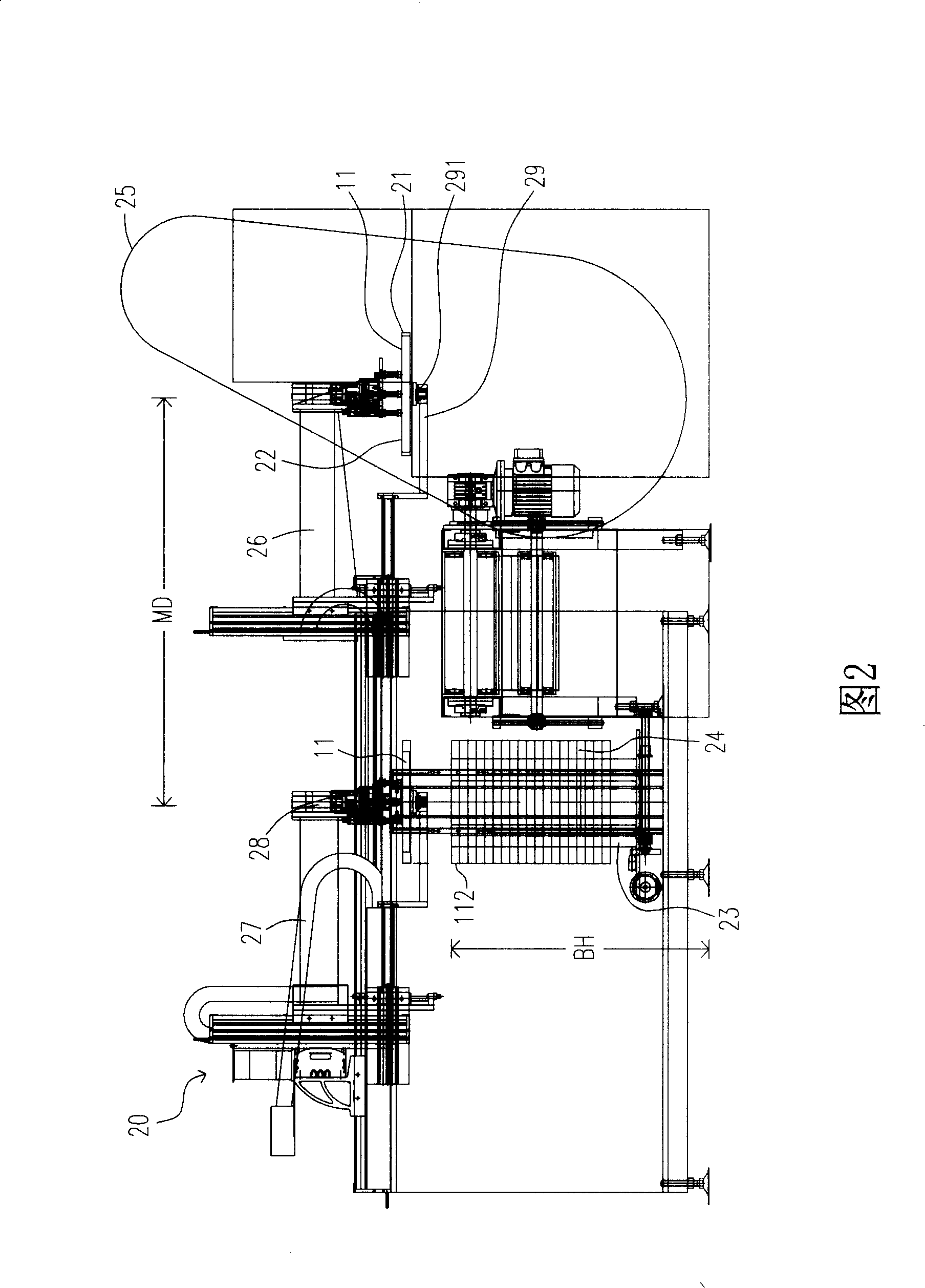

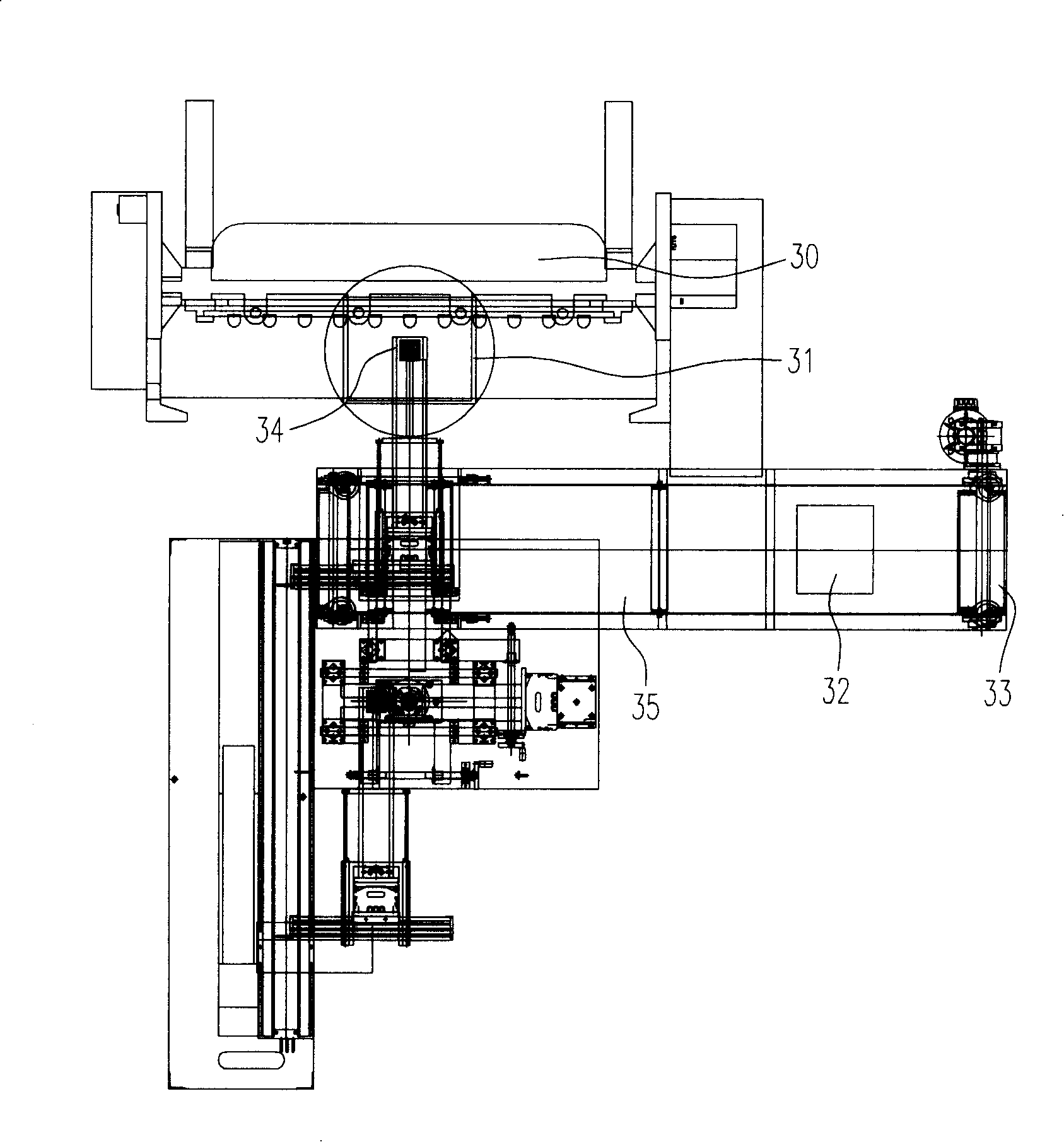

[0059] see figure 1 , showing the processing flow of the dismantling mode of the present invention, which is a dismantling method for reclaiming a liquid crystal display (LCD), the steps of which include providing the panel 11 of the liquid crystal display 10, positioning the panel 11 as shown in Figure 2 One side 21 , cutting the first side 21 , performing the first rotation of the panel 11 , and cutting the second side 22 of the panel 11 , so as to facilitate sorting the first material 121 and the second material 122 of the panel 11 .

[0060] see again figure 1 , taking the LCD display 10 that is common and out of function on the market as an object, the method also includes firstly using an electric screwdriver (not shown in the figure) to remove the screws on the periphery of the LCD display 10 to remove the plastic shell 13 and the base 14, and then Adjust the accommodating space 24 of the feeding platform 23 as shown in Figure 2 to place the panel 11, and then position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com