Toughness excellent steel plate of welding heat influence part in ultra-high heat input welding

A welding heat-affected and ultra-high heat technology, applied in the field of steel plates, can solve the problems of insufficient synergistic effect and insufficient HAZ toughness improvement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

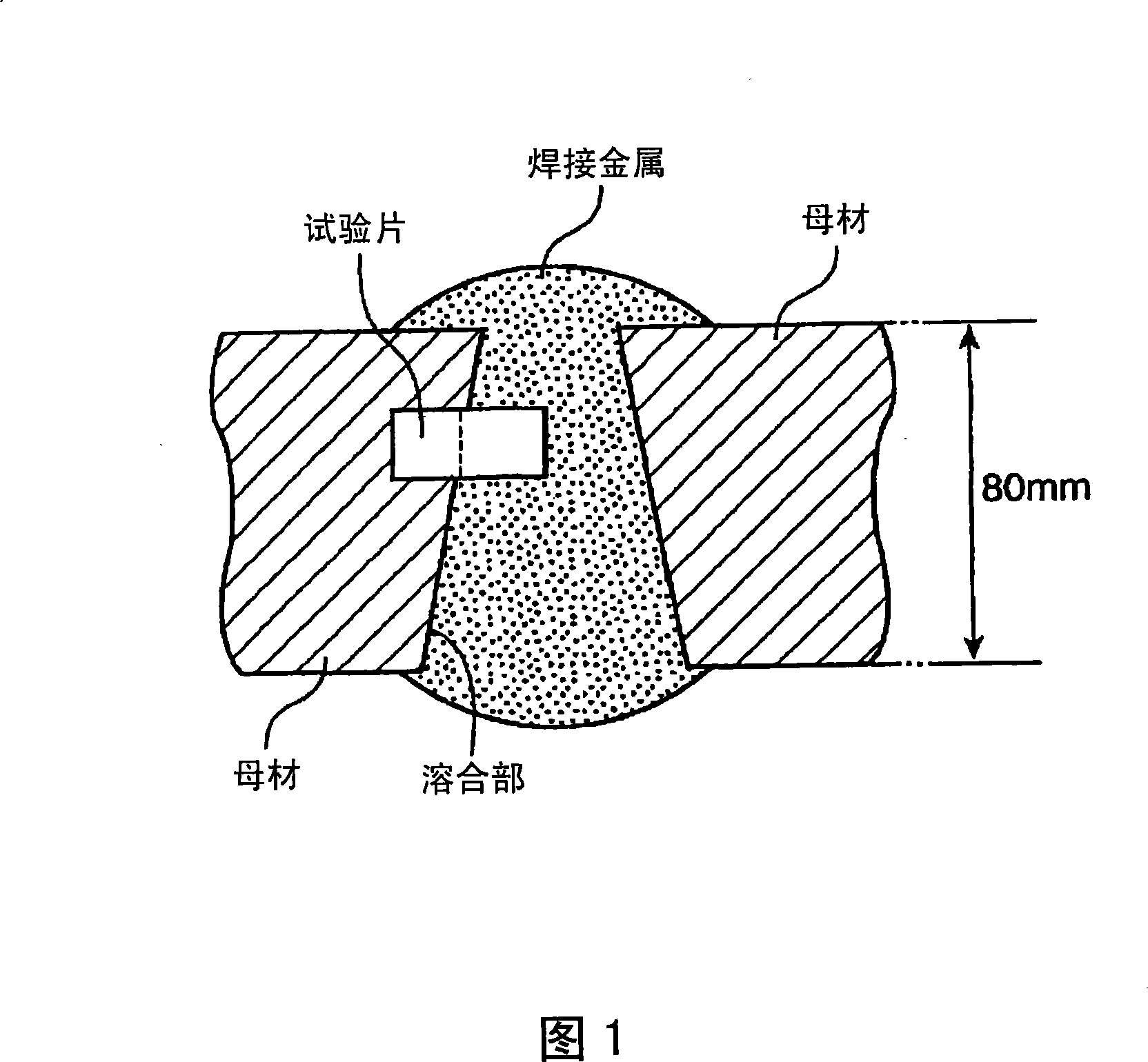

[0033] In order to achieve the above-mentioned problems, the inventors of the present invention have repeatedly studied factors affecting HAZ toughness during ultra-high heat input welding from various angles. As a result, it was concluded that the HAZ toughness of the steel plate is largely affected by the formation of embrittlement structures, and that the formation of embrittlement structures can be achieved by suppressing the coarsening of austenite in the high-temperature heating region and during cooling. It is prevented by finely dispersing the transformation nuclei that promote ferrite transformation. Previously, it was considered that the HAZ toughness could not be stabilized well because these factors were insufficient.

[0034] Therefore, the inventors of the present invention have made further studies on the assumption that CaS and TiN in the solidification stage during casting and MnS produced as nuclei are effectively utilized in order to finely disperse ferrite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com