Method for operating internal combustion engine

A technology for internal combustion engines and fuels, applied in mechanical equipment, engine control, machines/engines, etc., can solve the problems of reducing the proportion of fresh air, increasing fuel consumption, and deteriorating thermal characteristics of fuel-air mixture, so as to reduce fuel consumption and optimize fuel consumption The effects of simplification and reduction of the remaining gas fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

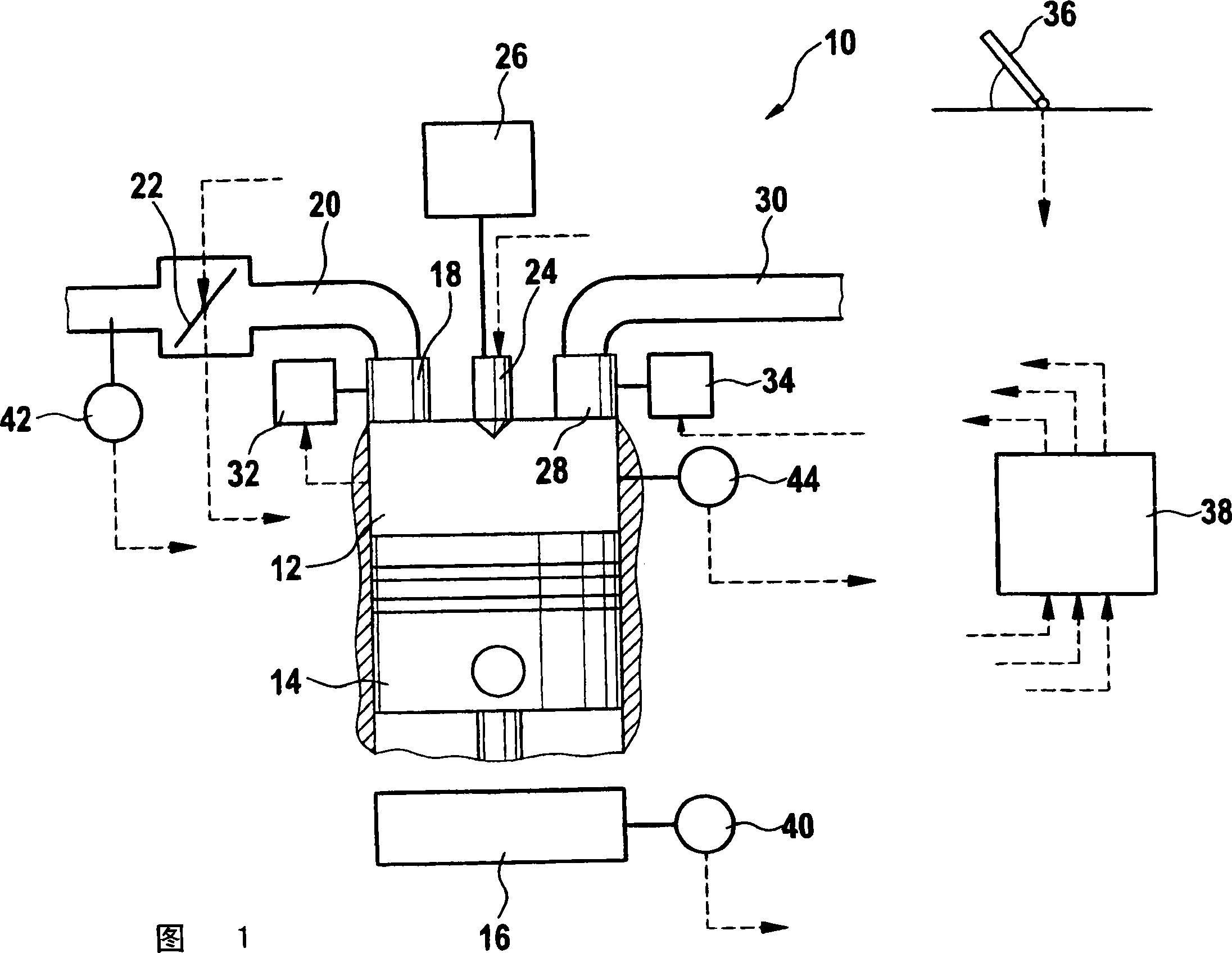

[0023] In FIG. 1 , the entire internal combustion engine is indicated by reference numeral 10 . This internal combustion engine is preferably used to drive a motor vehicle (not shown). Internal combustion engine 10 includes a plurality of cylinders, a cylinder with a combustion chamber 12 and a piston 14 being shown as an example in FIG. 1 . Piston 14 is connected to crankshaft 16 . Combustion air passes through intake valve 18 and intake passage 20 to combustion chamber 12 . The intake duct 20 has a throttle valve 22 for regulating the mass flow of fresh air. This fresh air mass flow is delivered to combustion chamber 12 via intake duct 20 .

[0024] Fuel is injected directly into combustion chamber 12 through injector 24 . The injector is fueled on its side by a high pressure fuel system 26 . The direct injection of fuel into combustion chamber 12 enables a more targeted influence of the HCCI-based operating mode of internal combustion engine 10 than a port injection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com