Microwave stirrer support for wave-rotating furnace

A technology of agitator and rotary wave furnace, which is used in household stoves/stoves, household heating, heating fuels, etc., can solve the problems of complicated production methods and installation processes, wear and tear, etc., and achieve the effect of saving raw materials and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The basic structure of the furnace body that is the same as that in the background art will not be repeated here.

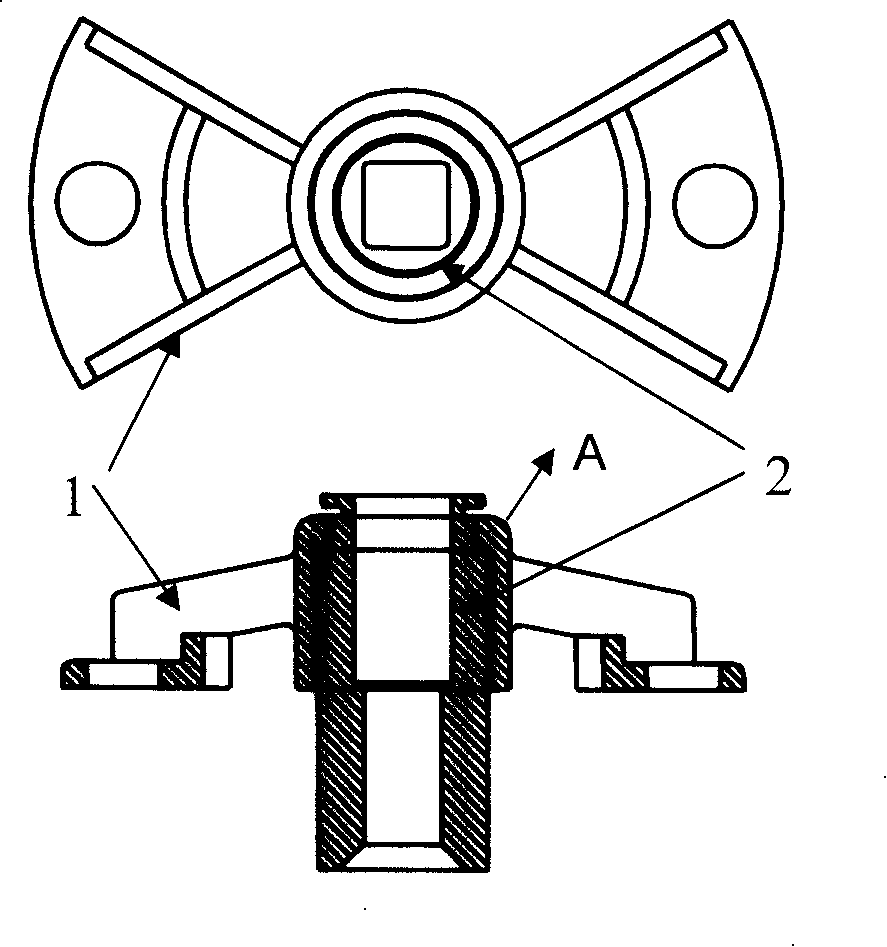

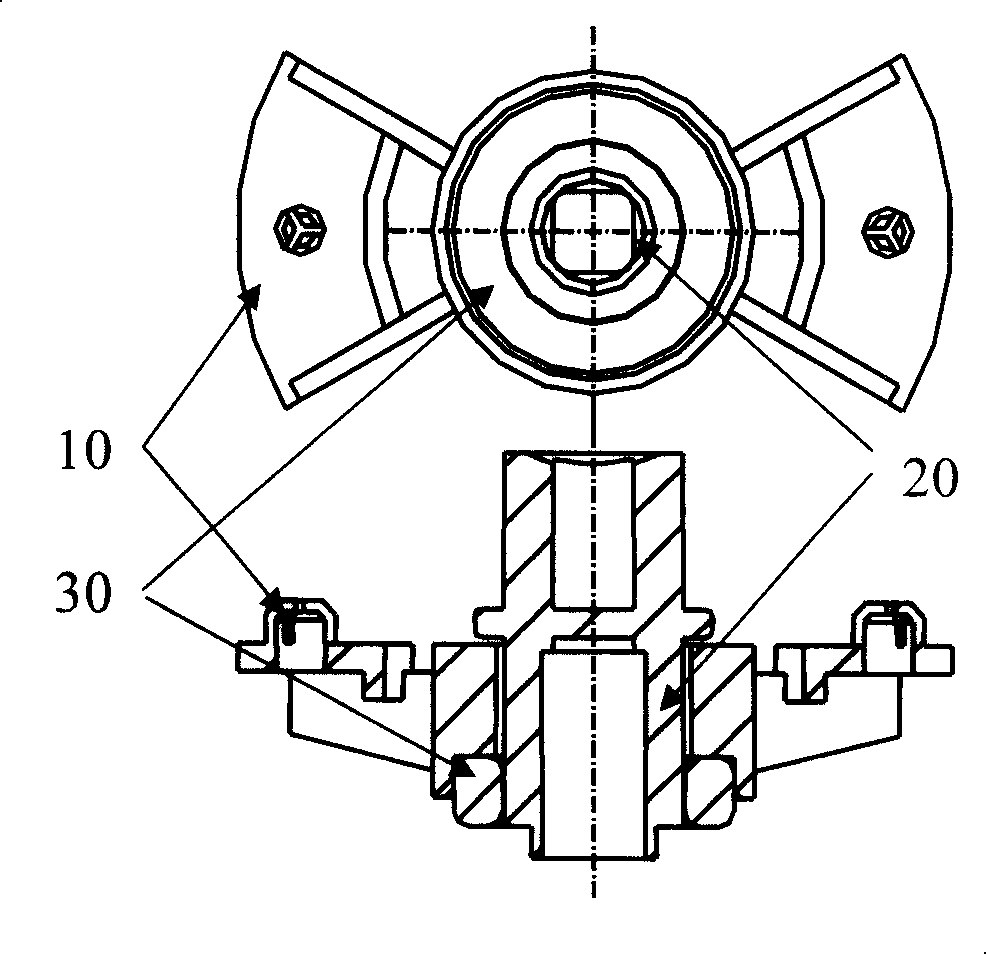

[0017] figure 2 It is a front view and a bottom view of the structure of the stirrer support of the present invention.

[0018] Such as figure 2 As shown, the microwave stirrer bracket of the rotary wave furnace includes a bracket 10, a shaft sleeve 20 and an "O" ring 30; each of the components is a separate component and assembled, and the "O" ring 30 Half of the ring is sunken in the bracket, the outer peripheral surface of the "O" ring 30 is matched with the bracket 10, and the inner peripheral surface of the "O" ring 30 is matched with the shaft sleeve 20, and the fit is interference fit. The "O" ring 30 is made of Teflon material, which has good wear resistance and certain elasticity; a circular groove that can accommodate the "O" ring 30 is formed between the upper part of the bracket 10 and the shaft sleeve 20, The upper surface of the "O" ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com