Fixing device for parts combination

A technology for fixing devices and parts, applied in the direction of connecting components, threaded fasteners, locking fasteners, etc., can solve the problems of complex technical solutions, not suitable for large-scale promotion and use, etc., to improve performance and safety, The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

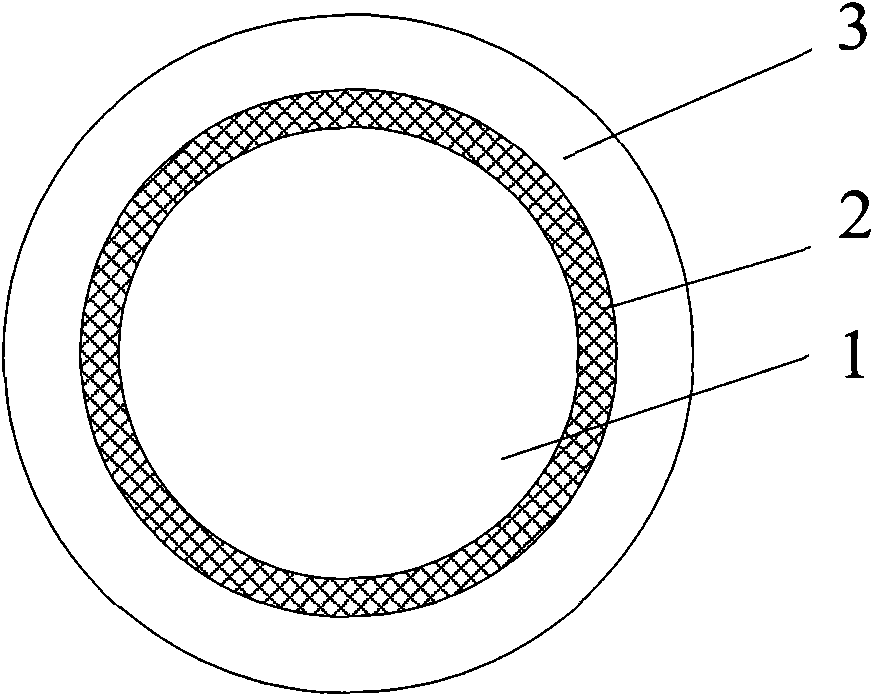

[0023] Such as figure 1 As shown, when the screw 1 and the nut 2 need to be closely combined, the filling layer 1 in liquid form can be added to the gap between the two parts. When the liquid is solidified, the parts can be tightly combined, and the air can also be prevented from entering, so as to realize the firm combination between the parts and achieve the purpose of safety and efficiency. The filling layer is in a liquid state when it is higher than normal temperature, and is solid in a normal temperature state. The cross section of the screw is circular. The inner diameter cross-section of the nut matches the screw. The outer diameter cross-section of the nut is circular.

Embodiment 2

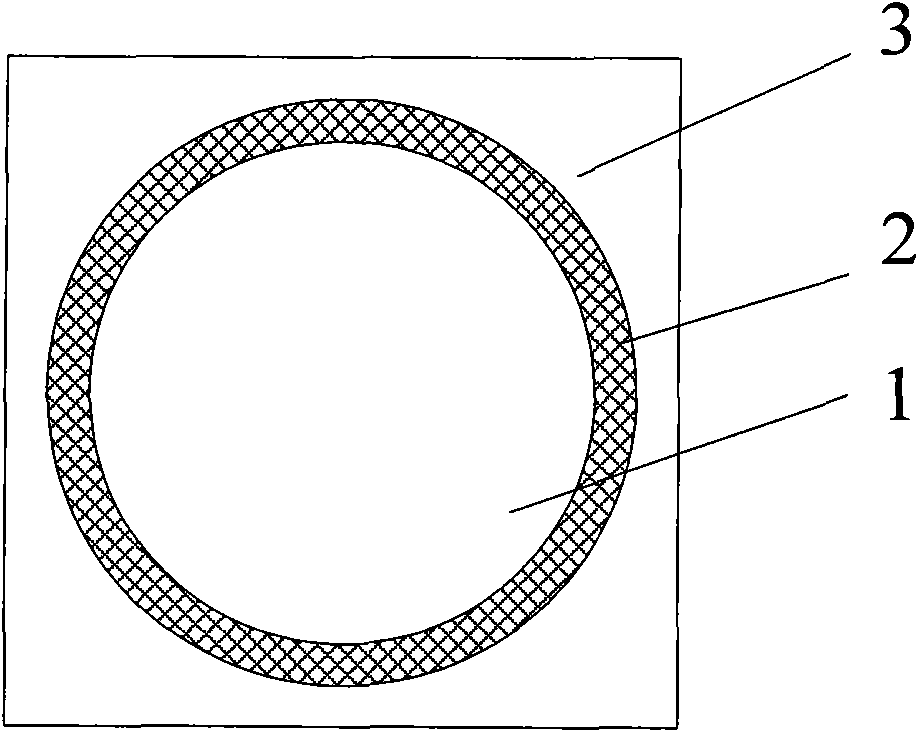

[0025] Such as figure 2 As shown, when the screw 1 and the nut 2 need to be closely combined, the filling layer 1 in liquid form can be added to the gap between the two parts. When the liquid is solidified, the parts can be tightly combined, and the air can also be prevented from entering, so as to realize the firm combination between the parts and achieve the purpose of safety and efficiency. The filling layer is in a liquid state when it is higher than normal temperature, and is solid in a normal temperature state. The cross section of the screw is circular. The inner diameter cross-section of the nut matches the screw. The outer diameter cross-section of the nut is square.

Embodiment 3

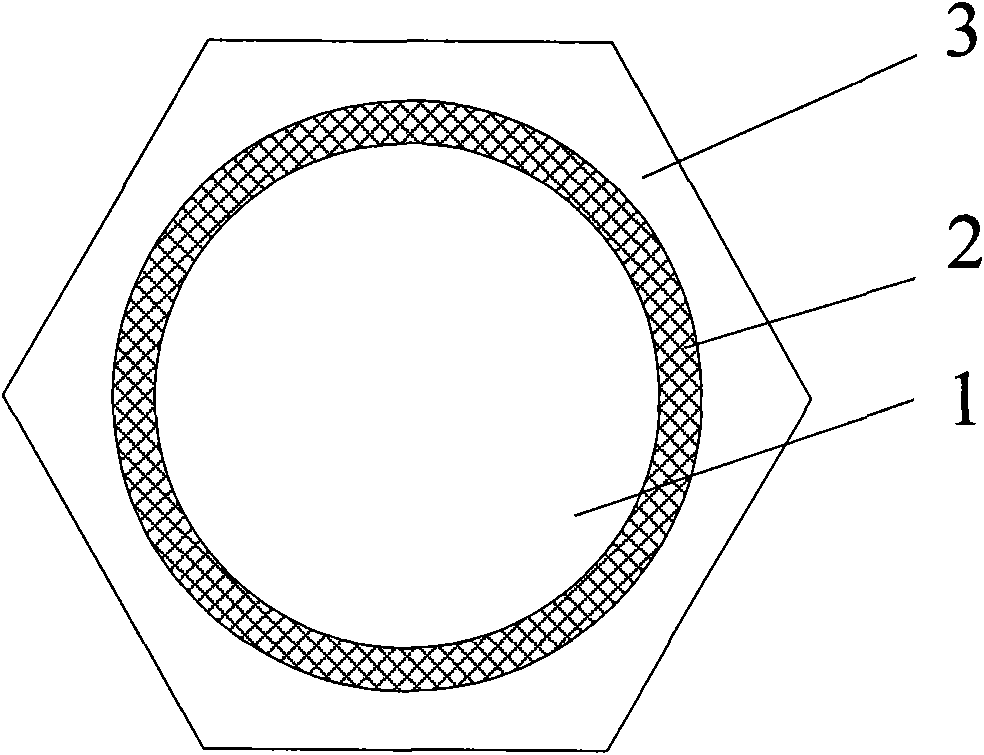

[0027] Such as image 3 As shown, when the screw 1 and the nut 2 need to be closely combined, the filling layer 1 in liquid form can be added to the gap between the two parts. When the liquid is solidified, the parts can be tightly combined, and the air can also be prevented from entering, so as to realize the firm combination between the parts and achieve the purpose of safety and efficiency. The filling layer is in a liquid state when it is higher than normal temperature, and is solid in a normal temperature state. The cross section of the screw is circular. The inner diameter cross-section of the nut matches the screw. The outer diameter cross-section of the nut is a regular hexagon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com