Circuit board assembly structure and its guide wave device

A technology for assembling structures and circuit boards, which is applied in the direction of circuit layout, electrical components, magnetic field/electric field shielding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

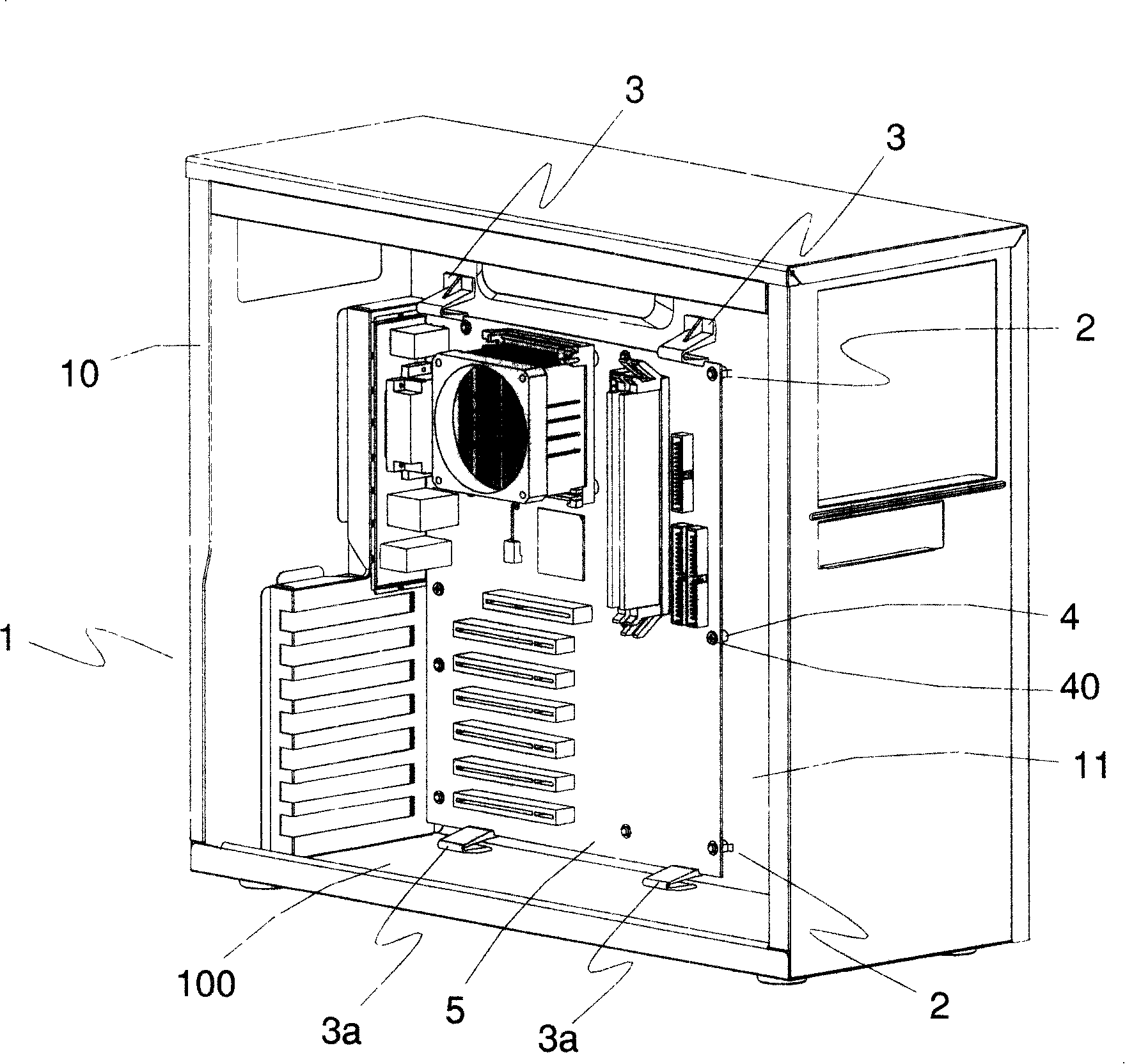

[0031] see figure 1 , figure 1 Disclose the circuit board assembly structure and its waveguide device described in the present invention, its structure includes:

[0032] A carrier 1 is a conductive material; in this embodiment, the carrier 1 includes a computer case 10 and a seat board 11, the seat board 11 is assembled on the computer case 10, and the computer case 10 has a shell The wall 100 is perpendicular to the seat plate 11;

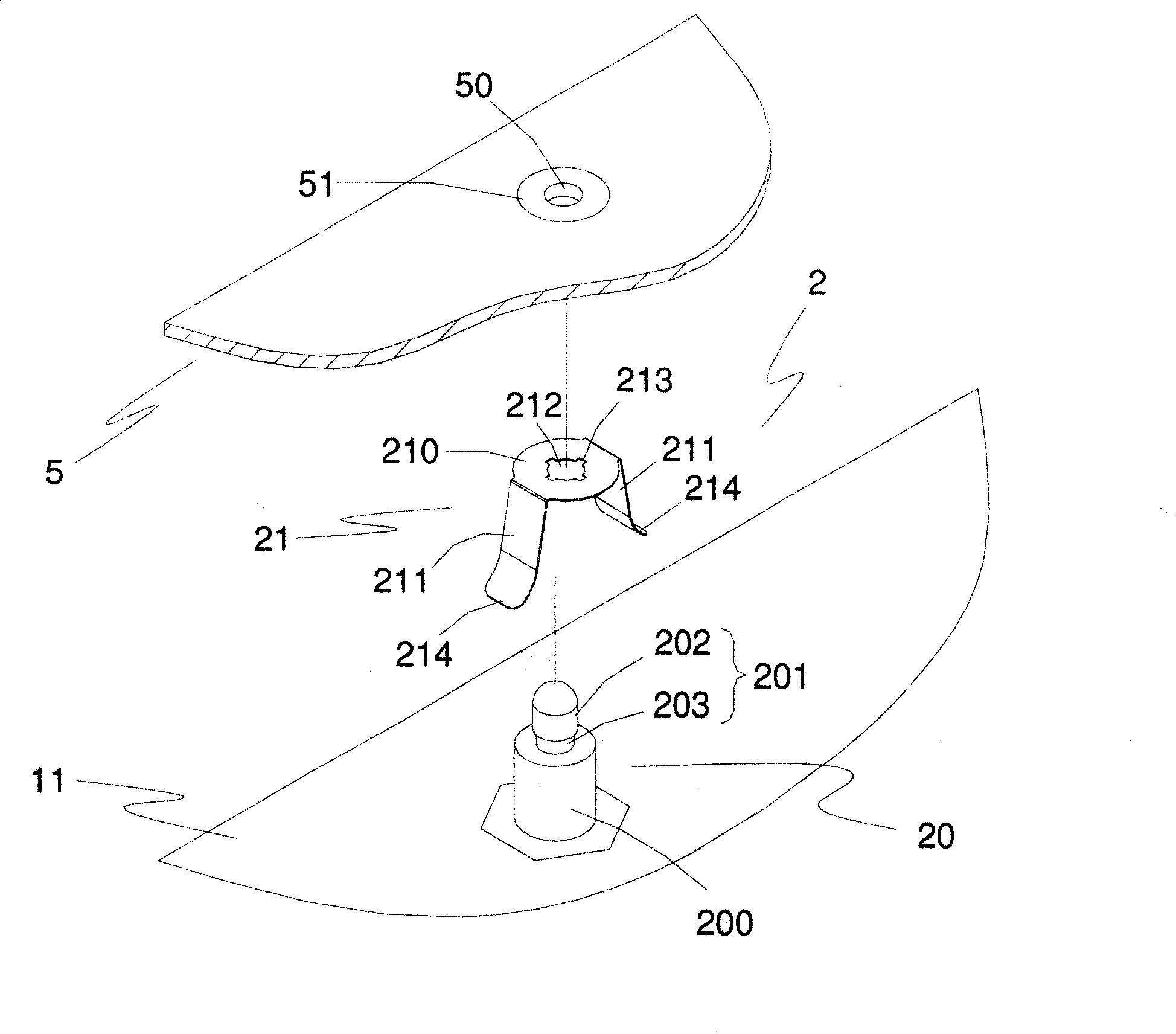

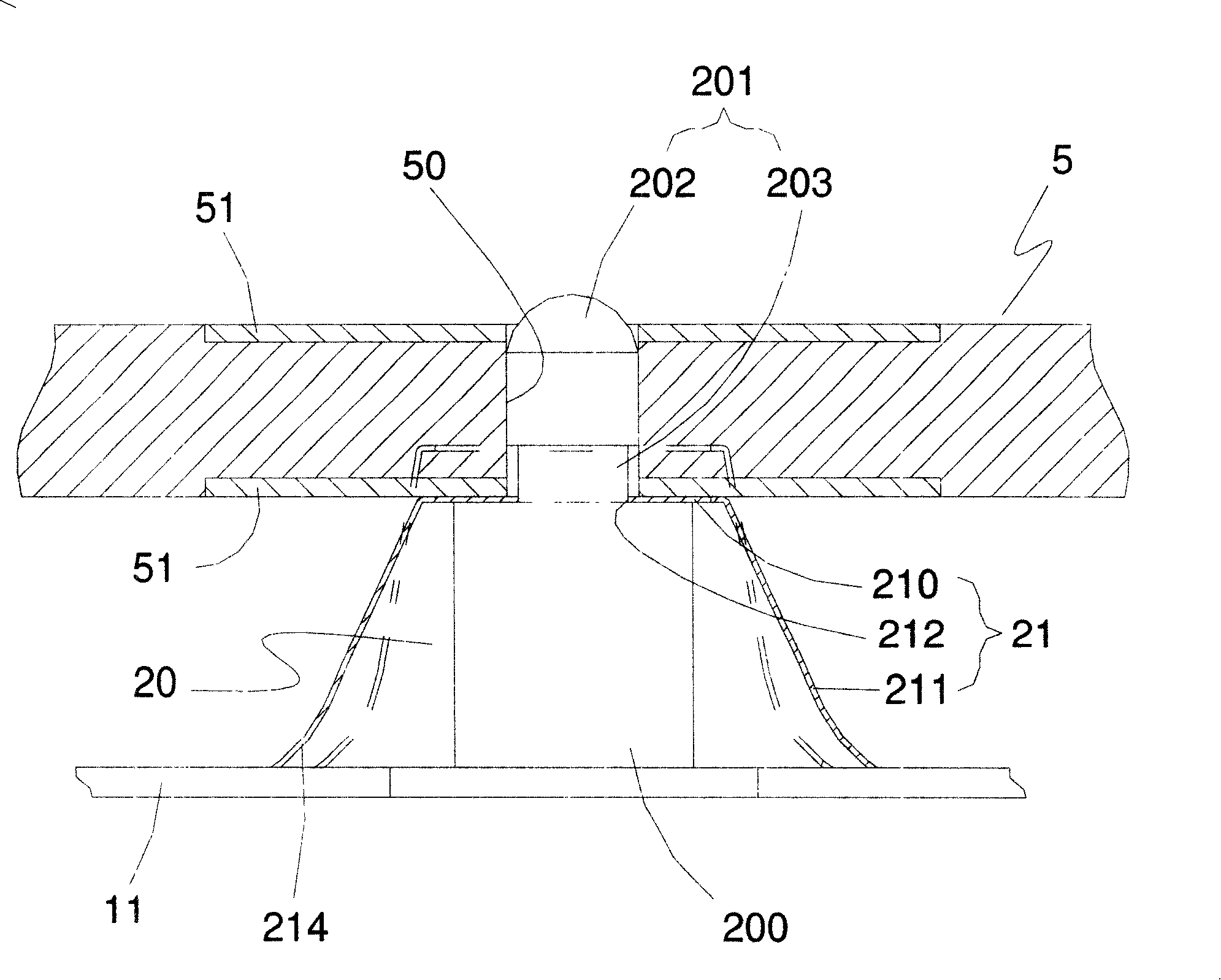

[0033] Several waveguide devices 2 are arranged on the carrier 1 and are used to support the circuit board 5 at an appropriate height and prevent the circuit board 5 from moving laterally, and can be electrically connected to the circuit board 5 and the carrier 1 for The electromagnetic wave leaked from the circuit board 5 is guided to the housing wall 100 to reduce electromagnetic interference (EMI). In this embodiment, there are eight sets of waveguide devices 2, all of which are arranged on the seat board 11, and the circuit board 5 is a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com