End milling cutter

A technology of end mills and tool holders, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., and can solve problems such as difficult and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

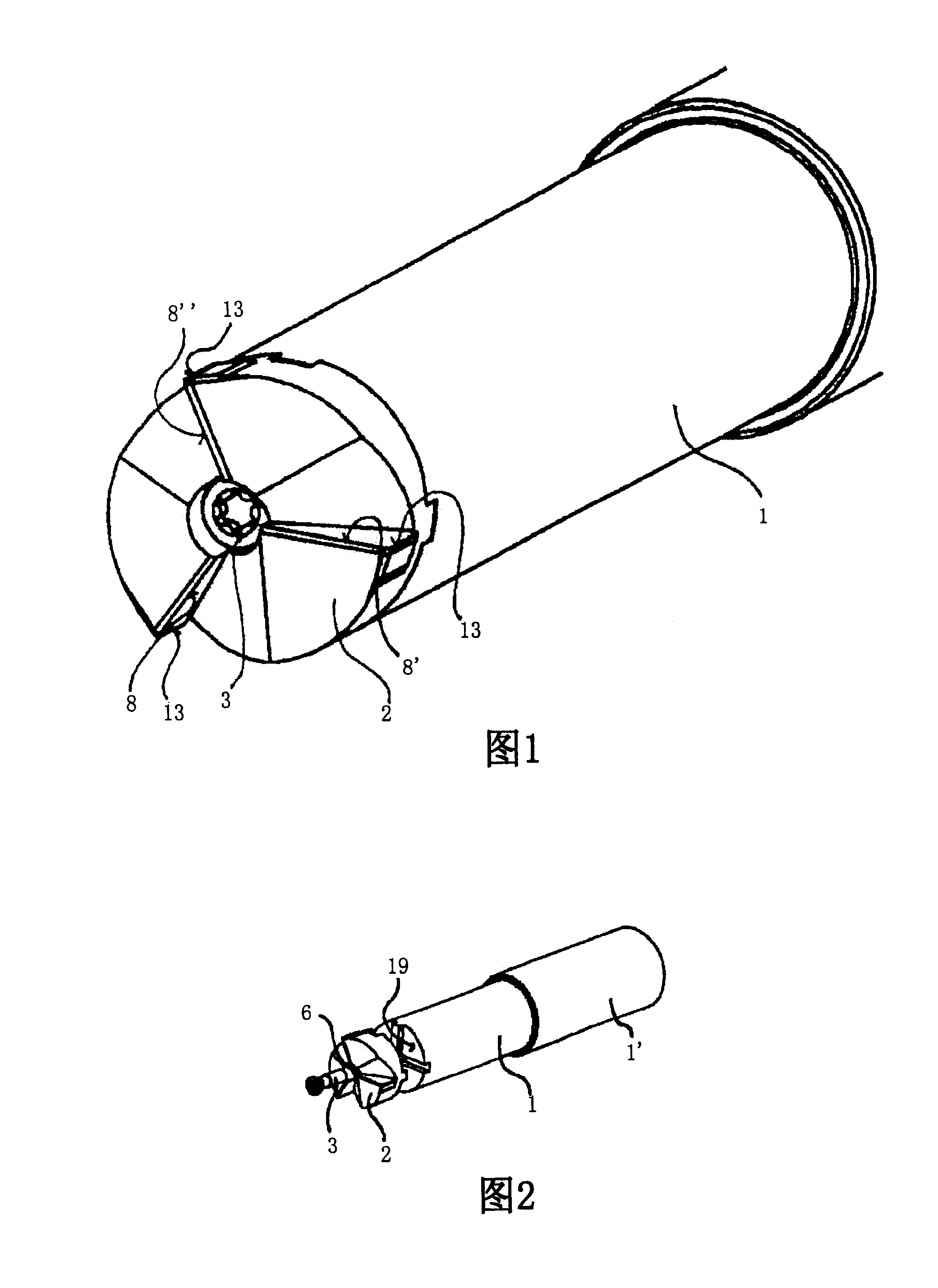

[0038] Referring to FIG. 1 , there is shown an end mill comprising a shank 1 and a cutting portion 2 which is integral and releasably secured to the end of the shank by a screw 3 . Figure 2 shows an exploded perspective view of the same end mill so that the three main components, namely the shank 1, the cutting part 2 and the screw 3, can be seen as separate parts which can be separated from each other and connected as a whole to form a stand A milling cutter which, in addition to the peripheral cutting edge 13, also has end cutting edges 8, 8', 8".

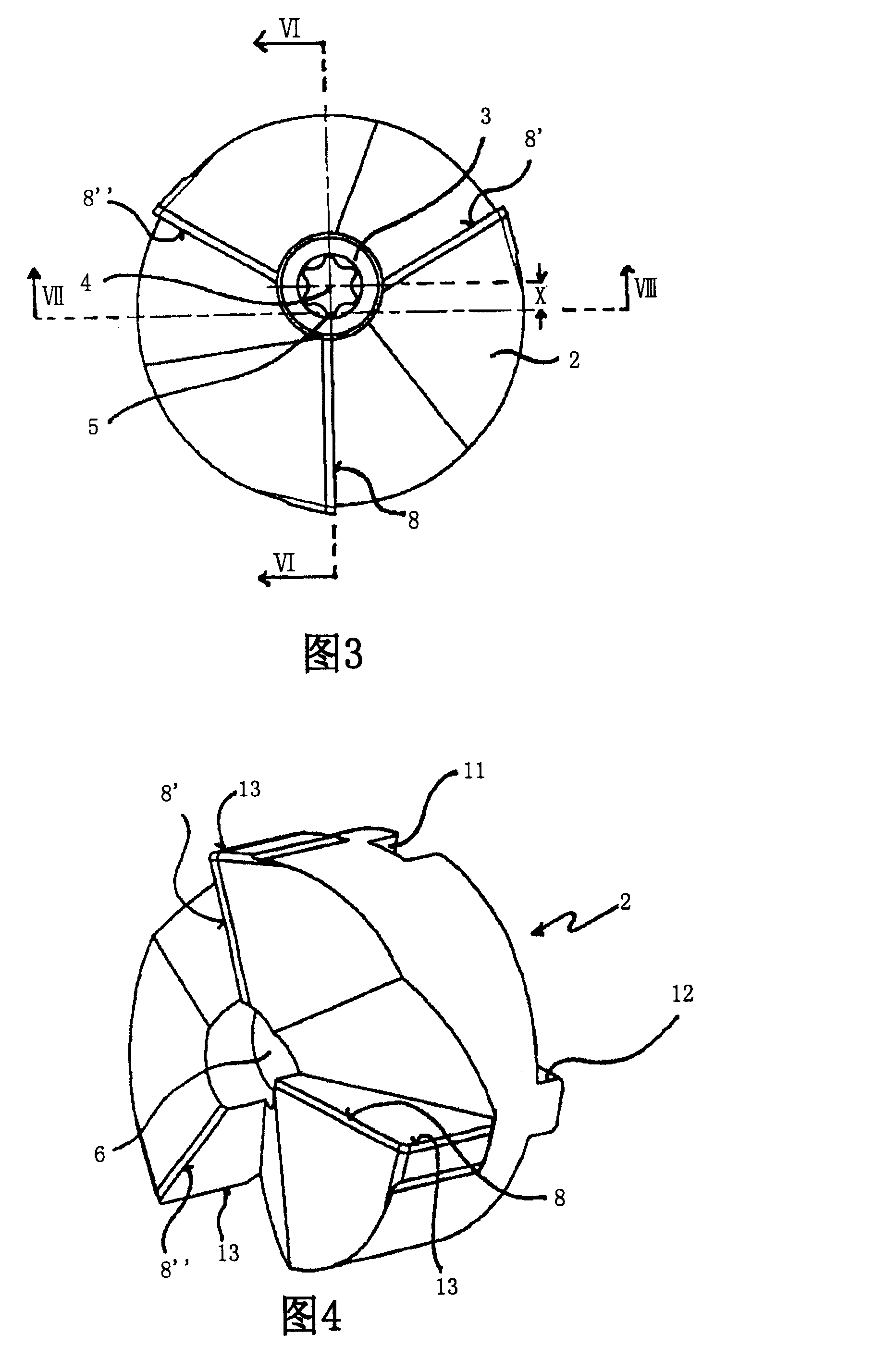

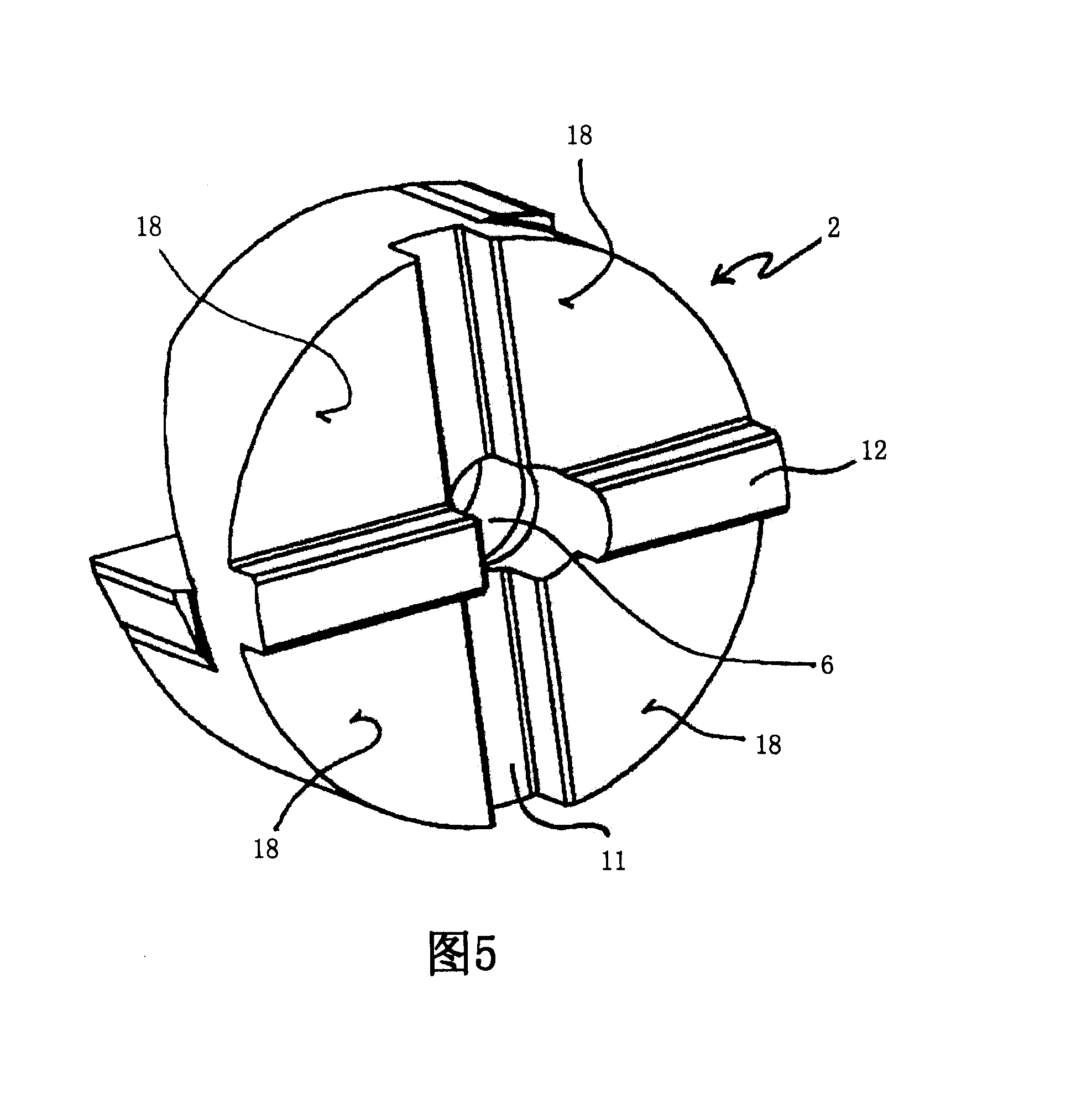

[0039] Further details will be apparent by reference to the enlarged views of FIGS. 3 to 8 .

[0040] The end view of the milling cutter shown in FIG. 3 mainly shows the end cutting part 2 and the fixing screw 3, which in this case has a so-called "Torx" drive, that is to say the fixing screw 3 has an opening, which adopts In the form of a hexagonal star with a rounded tip and a transition, a drive wrench of corresponding constr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap