Method for measuring crane hoisting weight and counter weight and force moment controlling method and system

A technology of a control system and a measurement method, applied in the field of crane hoisting weight measurement and crane moment control system, can solve problems such as increasing crane cost, and achieve the effects of increasing cost, simple calculation process and good detection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

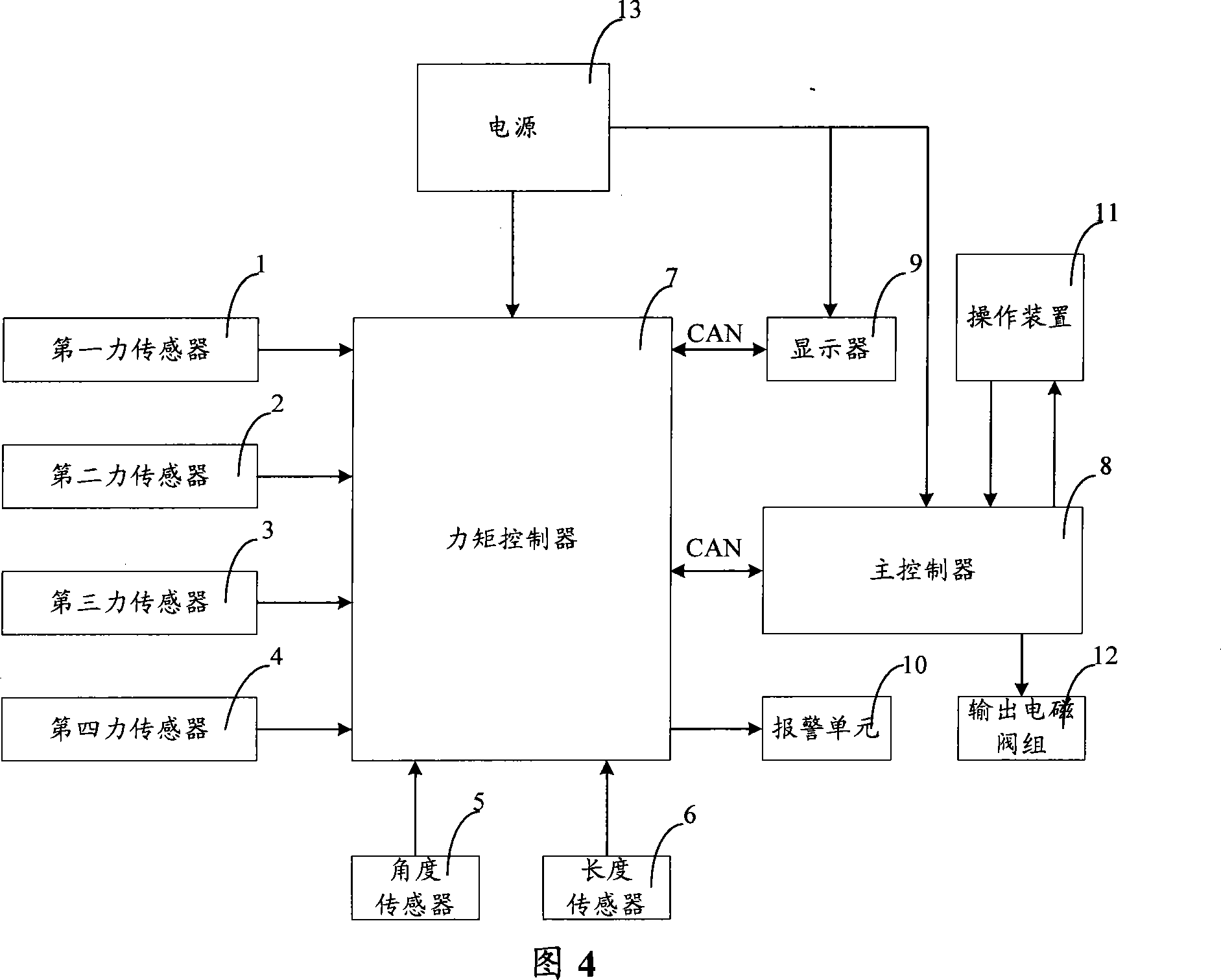

[0084] During the lifting process of the crane, in order to prevent accidents such as overturning or bending, it is necessary to estimate the lifting weight of the crane. In the prior art, the hoisting weight detection method adopted by the crane is to detect the boom length, the boom angle and the pressure value of the amplitude oil cylinder, and then calculate the hoisting weight of the crane based on the above values. The problems of the above-mentioned hoisting weight measurement method have been explained in the background technology. At first, the present invention provides a crane hoisting weight measurement method, which provides the basic premise for the crane moment control method described later and constitutes its main difference from the prior art. technical characteristics.

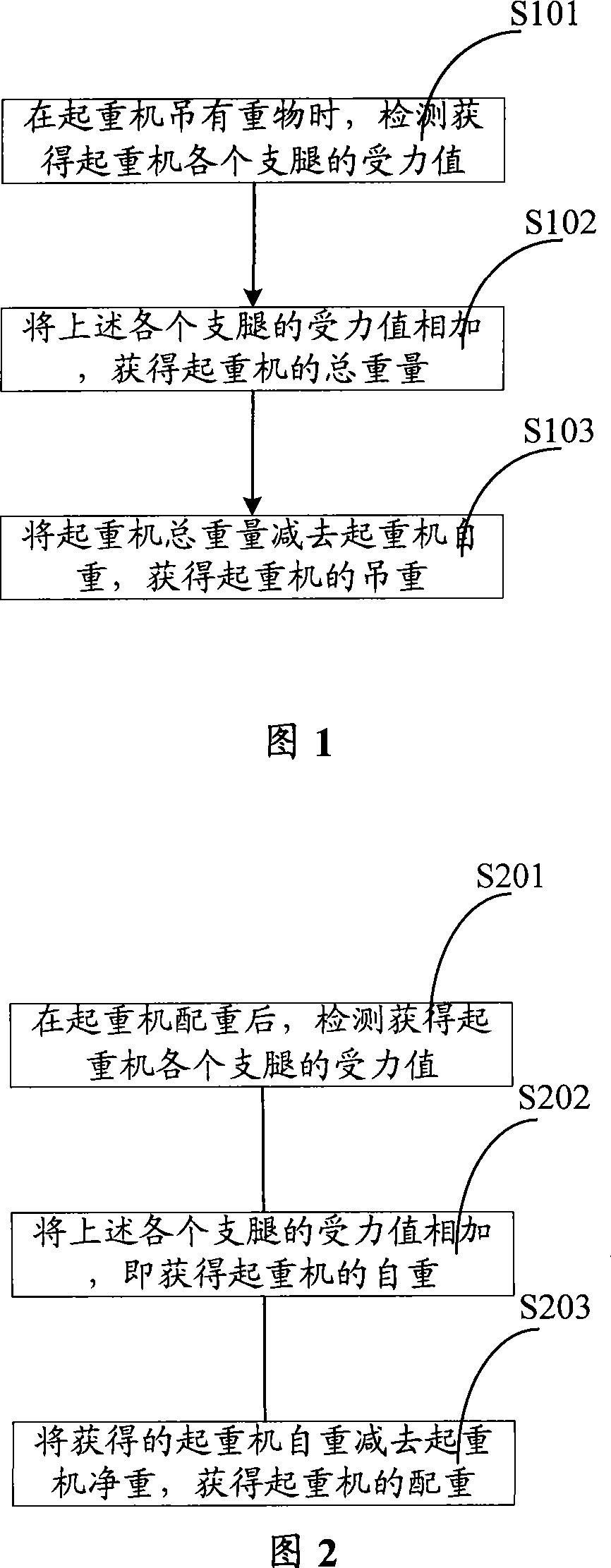

[0085] Please refer to FIG. 1 , which is a flow chart of the method for measuring the hoisting weight of a crane provided by the first embodiment of the present invention. This example will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com