Alternating current frequency conversion tyre crane

A tire crane, AC frequency conversion technology, applied to cranes and other directions, can solve the problems of high cost of DC motors, troublesome maintenance, and limited use of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

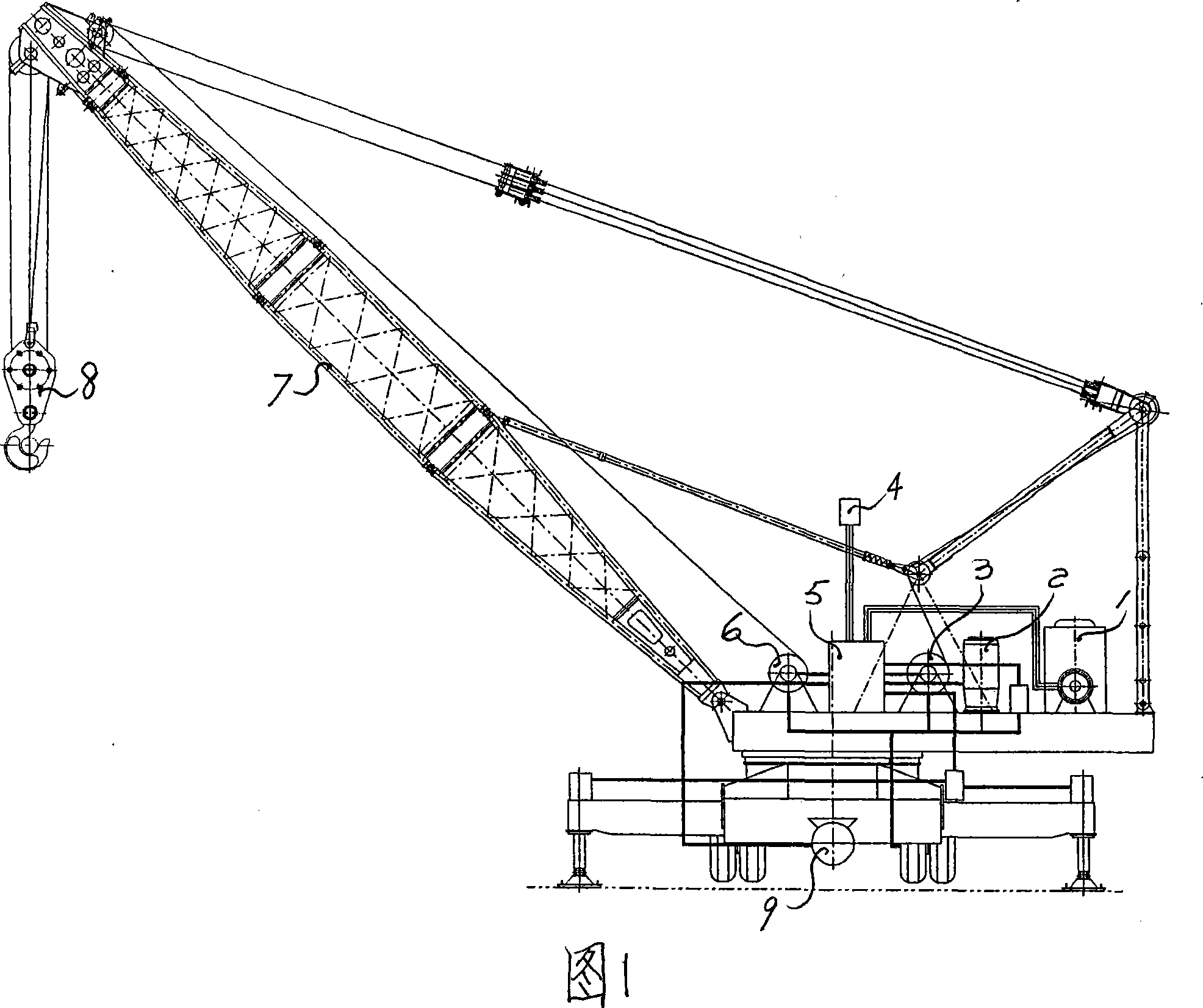

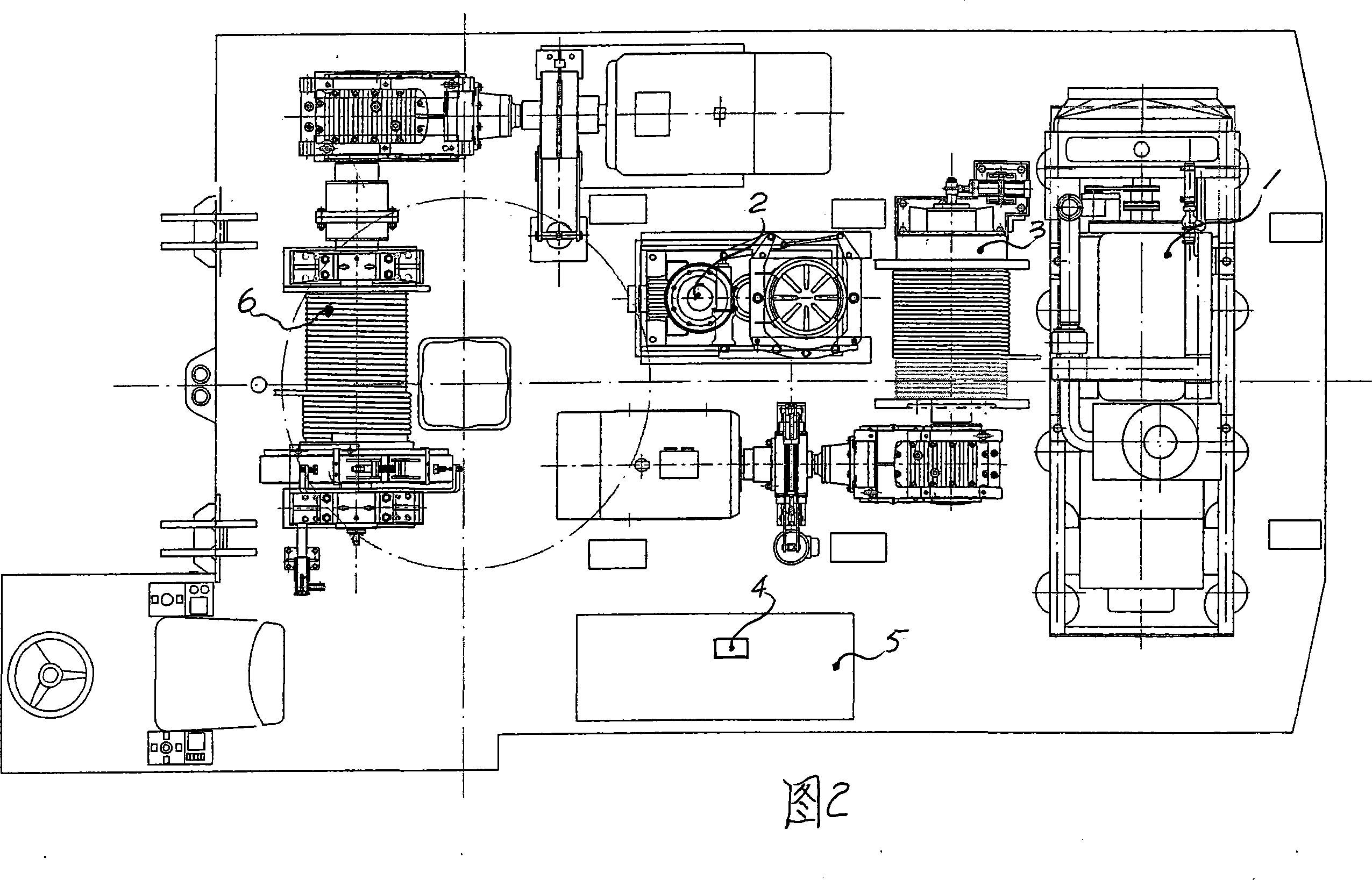

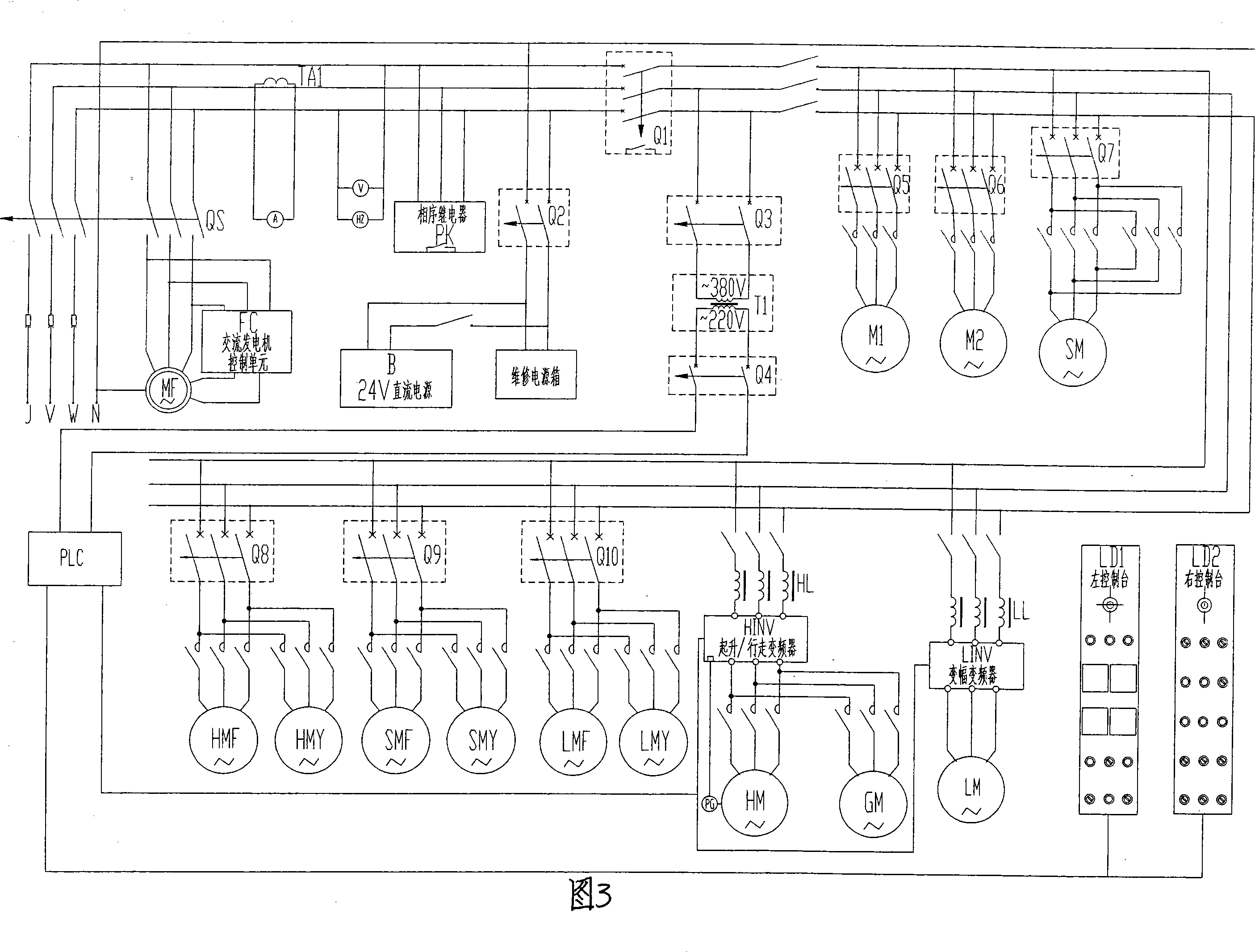

[0005] The present invention solves the high cost and inconvenient maintenance of DC motors and their speed regulating systems used in the hoisting, turning, driving, and jib luffing of existing port tire cranes, and the inability to use the existing AC power sources in ports, resulting in energy Waste and environmental pollution problems. For this reason, the present invention changes DC generator into AC generator and the DC motor of hoisting, turning, driving and boom luffing becomes AC motor. By adopting the AC motor, the stepless speed regulation can be realized conveniently with the existing frequency conversion technology. The present invention will be further described in conjunction with the above accompanying drawings. , the luffing mechanism 3, the hoisting mechanism 6, the boom 7 and the hook 8 are the same, and the changed part is to change the DC generator driven by the diesel engine into an AC generator to form a diesel AC generator set 1, and the resulting 380 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com