Automobile transmission-gear box electromagnetic clutch

A technology of automobile gearbox and clutch, applied in the field of clutch, can solve the problems of high fuel consumption, inconvenient automatic control of clutch, complicated structure, etc., and achieve the effect of smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

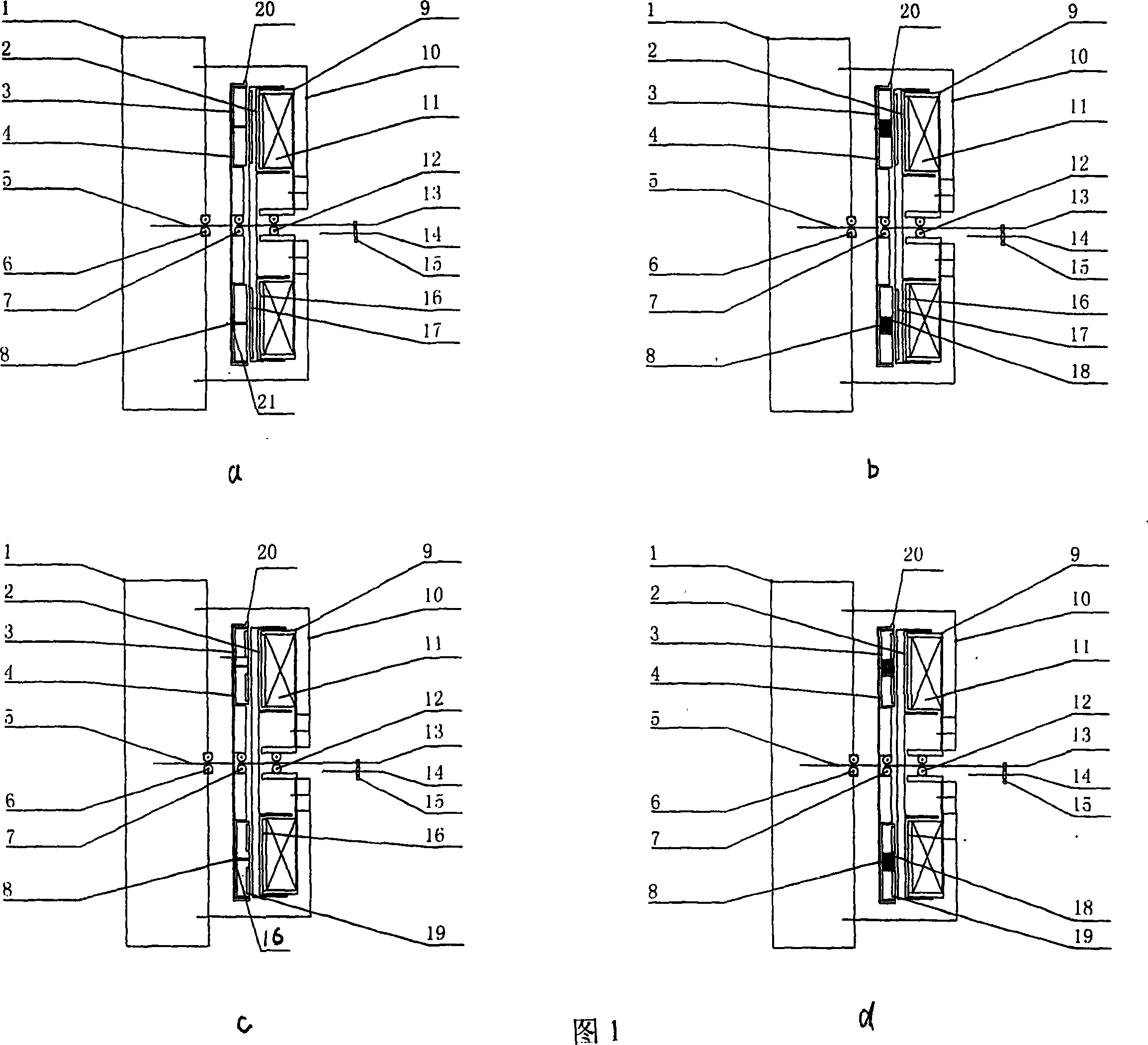

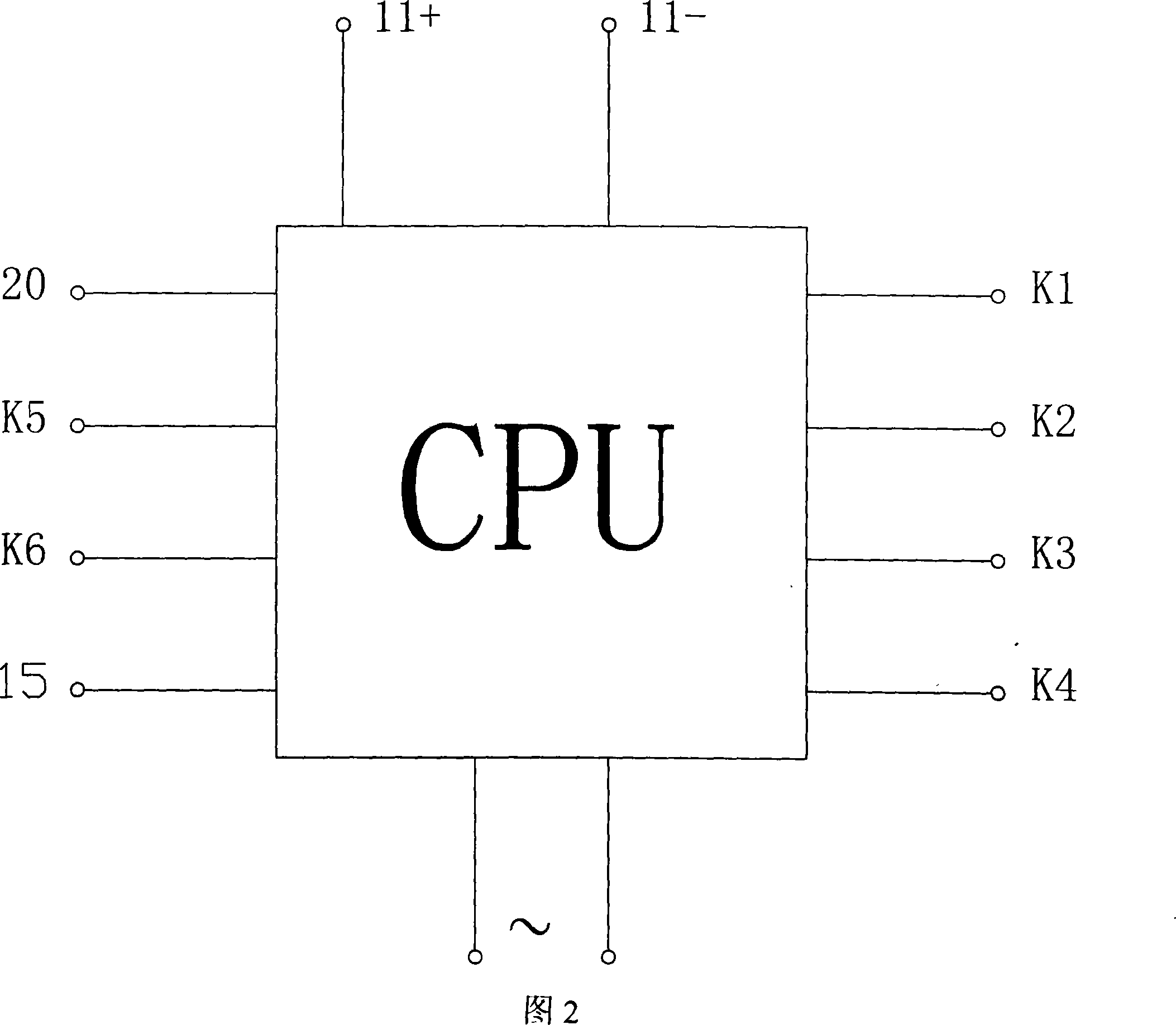

[0014] The clutch driven disc 2 of the present invention is fixed on the first shaft 13 of the gearbox, the wheel speed sensor 15 is housed on the second shaft 14 of the gearbox, the flywheel disc 4 is fixed on the engine crankshaft 5, and the flywheel driven disc 3 passes through the flywheel from The moving disc fixing pin 8 is installed on the flywheel disc 4 and slides axially on the flywheel disc 4, the engine crankshaft 5 is equipped with bearing bushes 6, bearings 7, etc., the coil 11 is fixed on the coil case 9, and the coil case 9 is fixed on the gearbox On the front end of the housing 10, the gearbox housing 10 is connected with the engine block 1, the concave part of the clutch driven disc 2 is wrapped on the protruding part of the coil cover 9, and the clutch driven disc and the coil cover are slidingly fitted, the gearbox The housing 10 is equipped with an engine speed sensor 20 . The flywheel driven disk 3 is fixed on the flywheel disk 4 by the flywheel driven di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com