Member structure element temperature axial force measuring apparatus

A technology for structural components and measuring devices, which is applied in the field of temperature and axial force measuring devices for structural members of rod systems, can solve the problems of material nonlinearity, inaccurate calculation results, and non-reusability, etc., to achieve accurate measurement results and improve calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

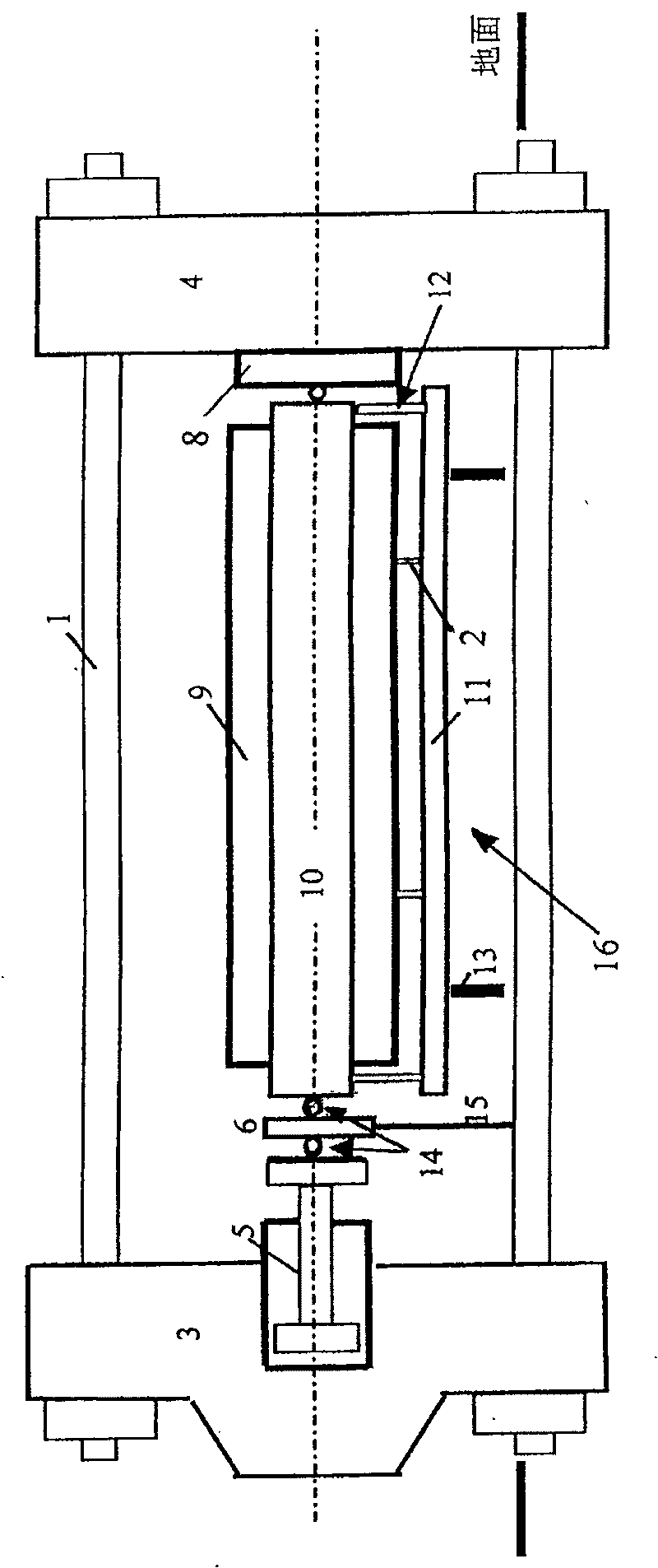

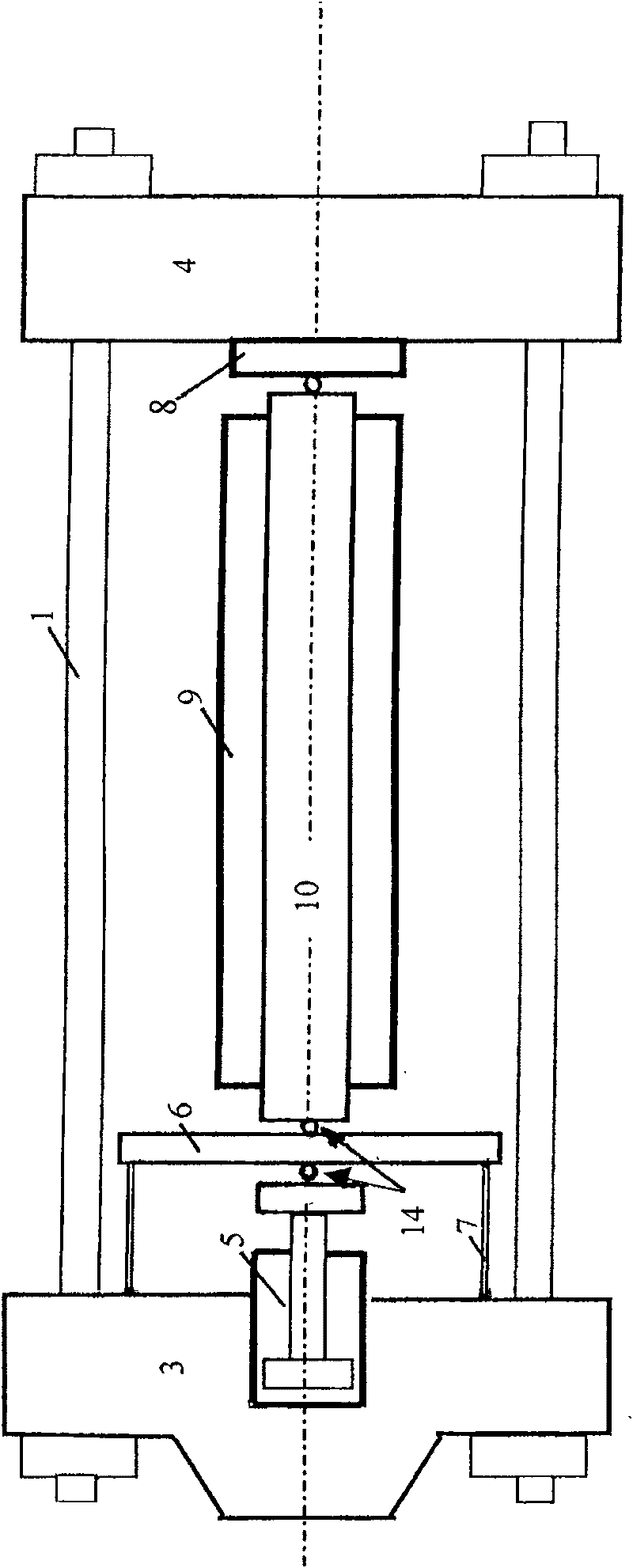

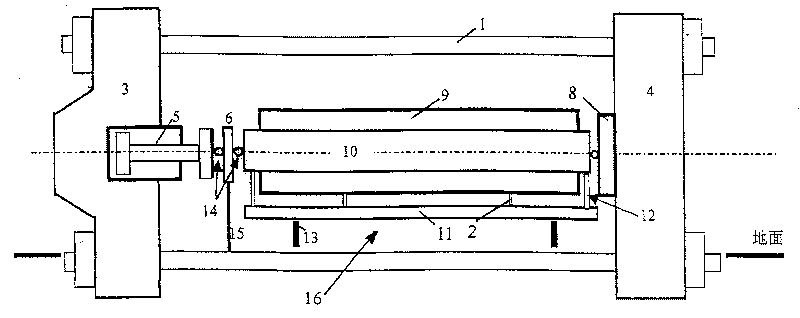

[0015] Embodiments of the device for measuring the temperature and axial force of the structural member of the rod system of the present invention will be described in detail below.

[0016] see figure 1 with figure 2 According to the present invention, the device for measuring the temperature and axial force of the structural member of the bar system includes a microcomputer-controlled electro-hydraulic servo pressure testing machine, a heating temperature control system, a restraining beam system, a pressure sensor 8 and a component positioning device 16 .

[0017] Microcomputer-controlled electro-hydraulic servo pressure testing machine is composed of reaction frame, loading cylinder and its control system. The reaction frame is composed of the left beam 3, the right beam 4 and the column 1, forming a rigid frame, providing space for the installation components and balancing various forces applied and generated during the test. The loading oil cylinder 5 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com