Expansion reel mandrel

A movement, axial technology used in the field of fixing/clamping spreader segments and/or locking slats to solve problems such as production interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

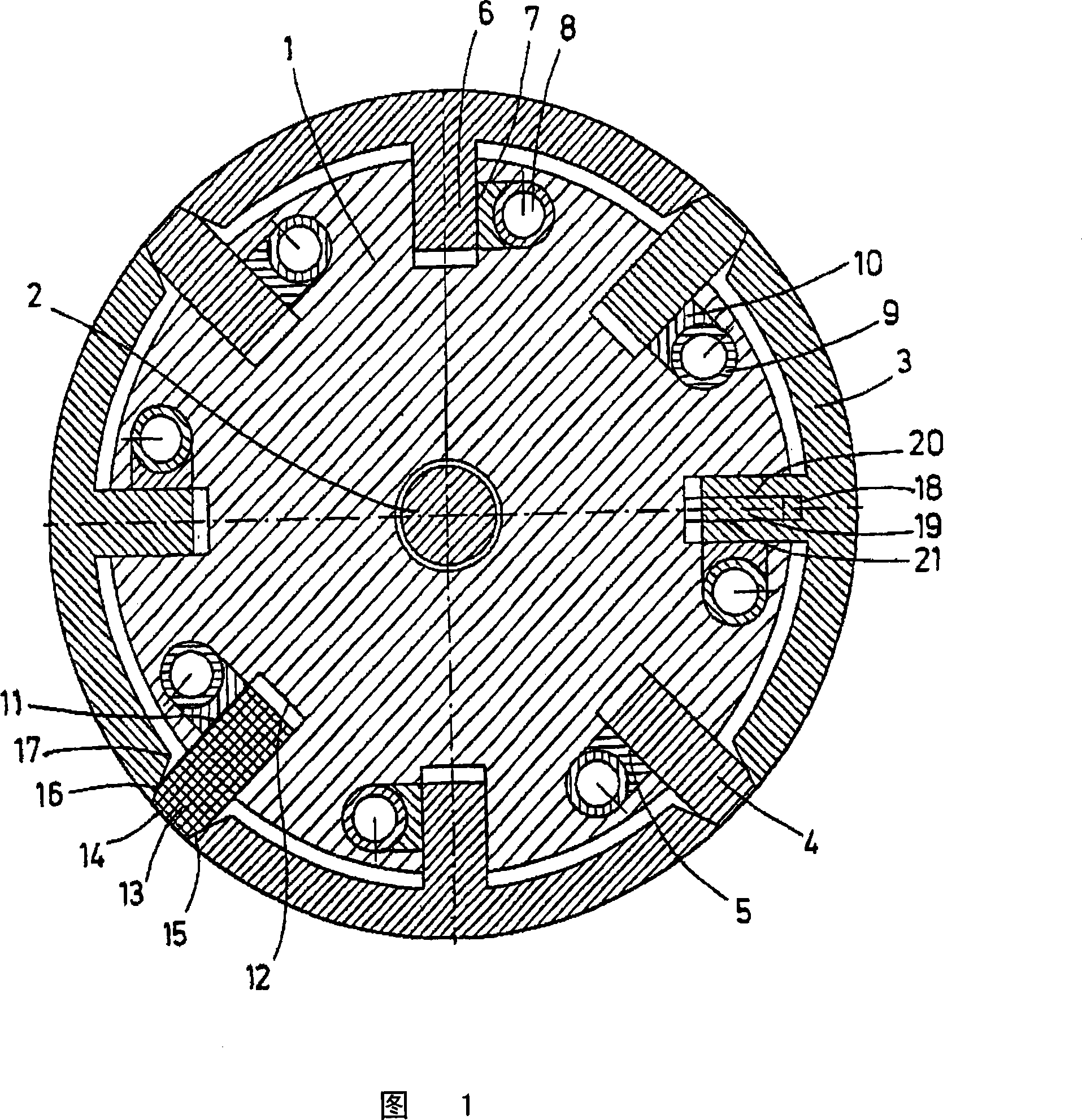

[0022] The single figure shows a cross-section of a coiler mandrel 1 which has an operating lever 2 in its central bore. The expansion segment 3 and the locking strip 4 are positioned radially in the guide groove 5 by means of the operating lever 2 . In this case, the expansion segments 3 and the locking strips 4 form a closed circle in the radially outer position. In the radially inner position, a gap is produced between the expansion segments 3 because the locking strips 4 are positioned radially further inward.

[0023] Each expansion segment 3 is held and guided in the guide groove 5 by means of a web 6 . In the side wall 7 of the guide groove 5, an axially extending hole 8 is incorporated. This hole 8 opens towards the guide groove 5 . Put the hose 9 into this hole 8 . In the embodiment shown, a clamping piece 10 is arranged between the hose 9 and the connecting piece 6 . In another embodiment, the hose 9 is in direct contact with the connecting piece 6 (not shown). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com