A device comprising a sensor module

A sensor module and sensor technology, applied in the direction of radiation control devices, semiconductor devices, electric solid devices, etc., can solve problems such as difficulties, unfavorable devices, expensive, etc., and achieve the effects of saving packaging, low cost, and precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

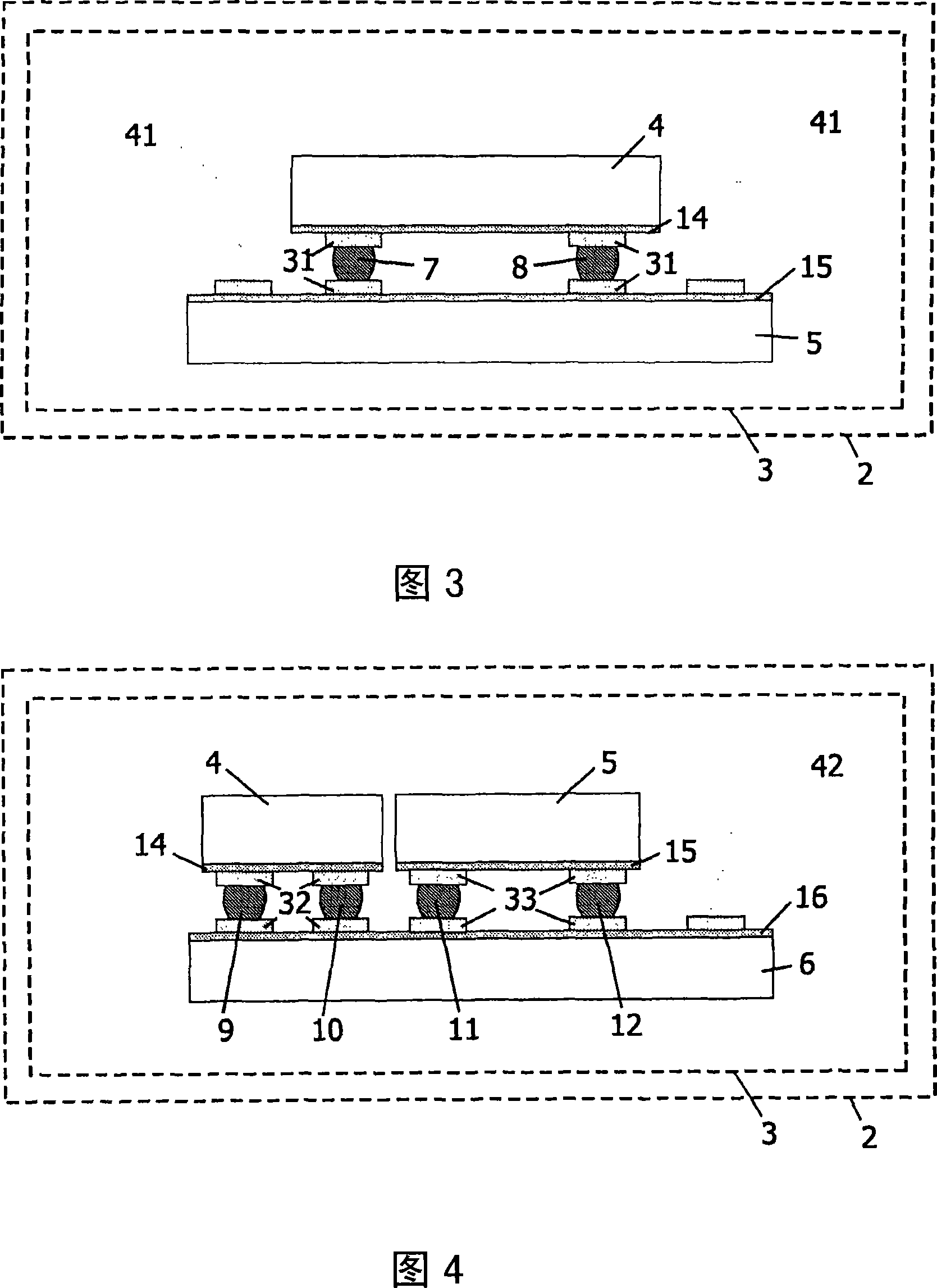

[0046] The sectional view (first option) of FIG. 3 represents a first embodiment of a sensor module according to the invention, which discloses a sensor module 2 comprising a package 3 . The package 3 comprises a first substrate 4 with a first functional layer 14 . The package 3 comprises a second substrate 5 with a second functional layer 15 . One of the functional layers 14, 15 comprises sensors not shown, while the other functional layer 14, 15 comprises active silicon which in a way provides an Application Specific Integrated Circuit (ASIC) function. A first number of pads 7 , 8 are connected to the two functional layers 14 , 15 via first bonding elements 31 , the other bonding elements being connected to leads 41 for electrical connection with a circuit not shown.

[0047] A method of monolithic integration of functional layers comprising at least one-dimensional sensors for sensing fields in at least one direction is disclosed, the sensors having an application specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com