Liquid-jet head and liquid-jet apparatus having same

A liquid jet head, liquid technology, used in printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

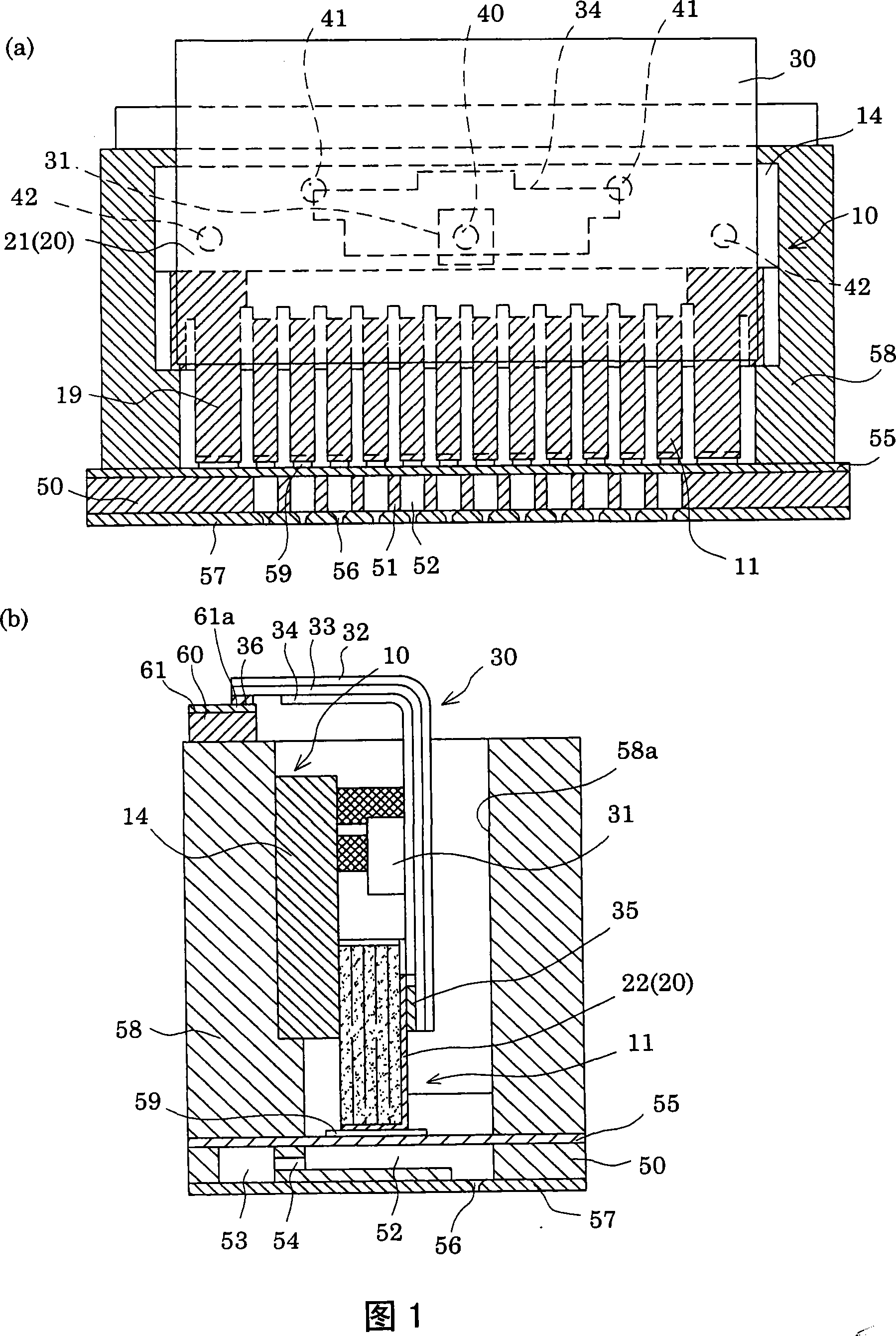

[0049] A head tank 58 having an ink supply path connected to a plurality of ink cartridges not shown is fixed to the vibrating plate 55 , and the piezoelectric element unit 10 is positioned and fixed with high precision in the head tank 58 . That is, the head box 58 is provided with a penetrating receiving portion 58a, and the piezoelectric element unit 10 is fixed on the inner surface of one side of the receiving portion 58a, and the front ends of each piezoelectric element 11 abut against the corresponding vibrating plate 55. Each island portion 59 on the area of each pressure generating chamber 52 on the upper side.

[0050] In the above-mentioned ink jet recording head, the displacement of the piezoelectric element 11 accompanying the supply of the drive signal causes a pressure fluctuation in the pressure generating chamber via the vibrating plate 55, and the pressure generation chamber is filled with the pressure fluctuation using the pressure fluctuation. Ink within c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com