Cylinder type workpiece code word machine

A type code machine, cylindrical technology, applied in the field of code type machines for cylindrical workpieces, can solve the problems of heavy maintenance workload, difficult hydraulic system troubleshooting, poor practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

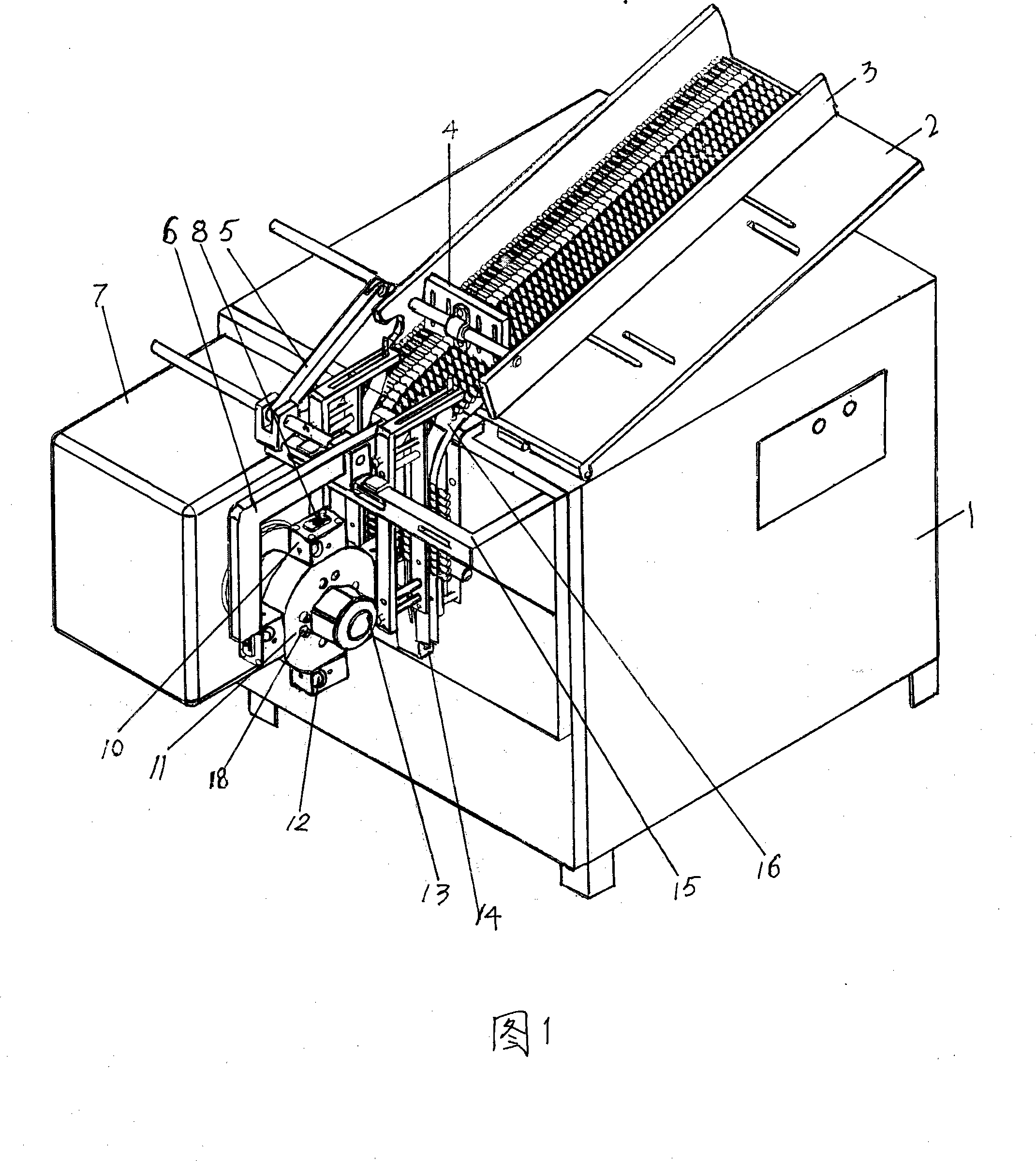

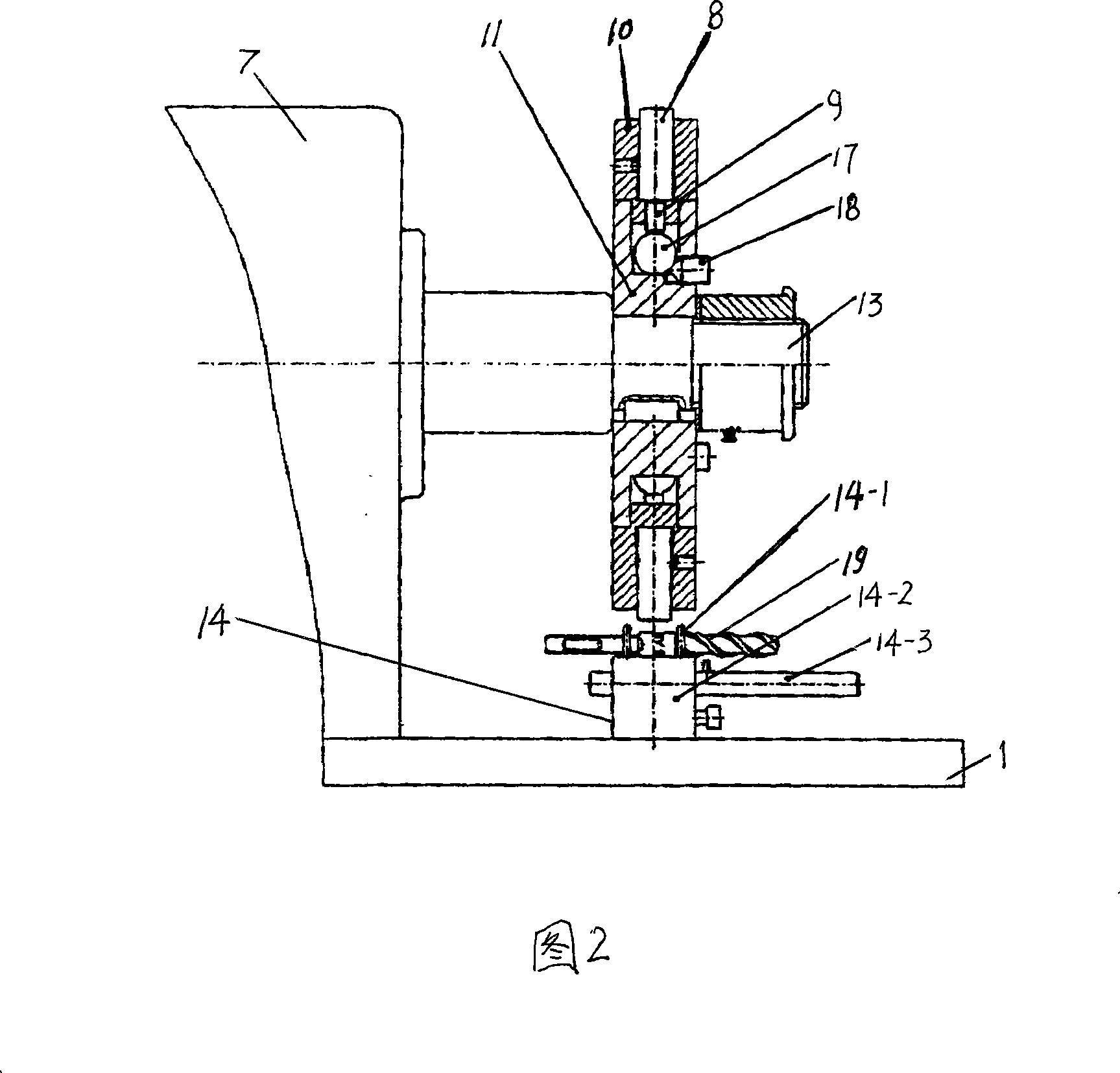

[0010] Referring to Fig. 1, a cylindrical workpiece coding machine, the body 1 has a built-in motor and its gearbox, the body 1 is obliquely mounted with an adjustable bracket 2, and the width-adjustable hopper 3 is mounted on the adjustable bracket 2, and the width can be adjusted. The front of the seasoning hopper 3 is connected to the curved material channel 16, and the front end of the width-adjustable hopper 3 is provided with a material pulling mechanism 4. The main shaft box 7 is fixed on one side of the front side of the fuselage 1, and the main shaft box 7 supports the main shaft 13. The gearbox drives the main shaft 13, and the front end of the main shaft 13 Fixed roller 11, at least one font box 10 is fixed around the roller 11, letter pattern mold 8 is embedded in the font box 10, cam 12 is equipped with on one side of font box 10, and specia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com