Rotating damper

A technology for rotating dampers and rotating shafts, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., and can solve the problems of large braking torque, large influence of braking torque, and non-rotating shafts, etc. To achieve the effect of reducing torque variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings.

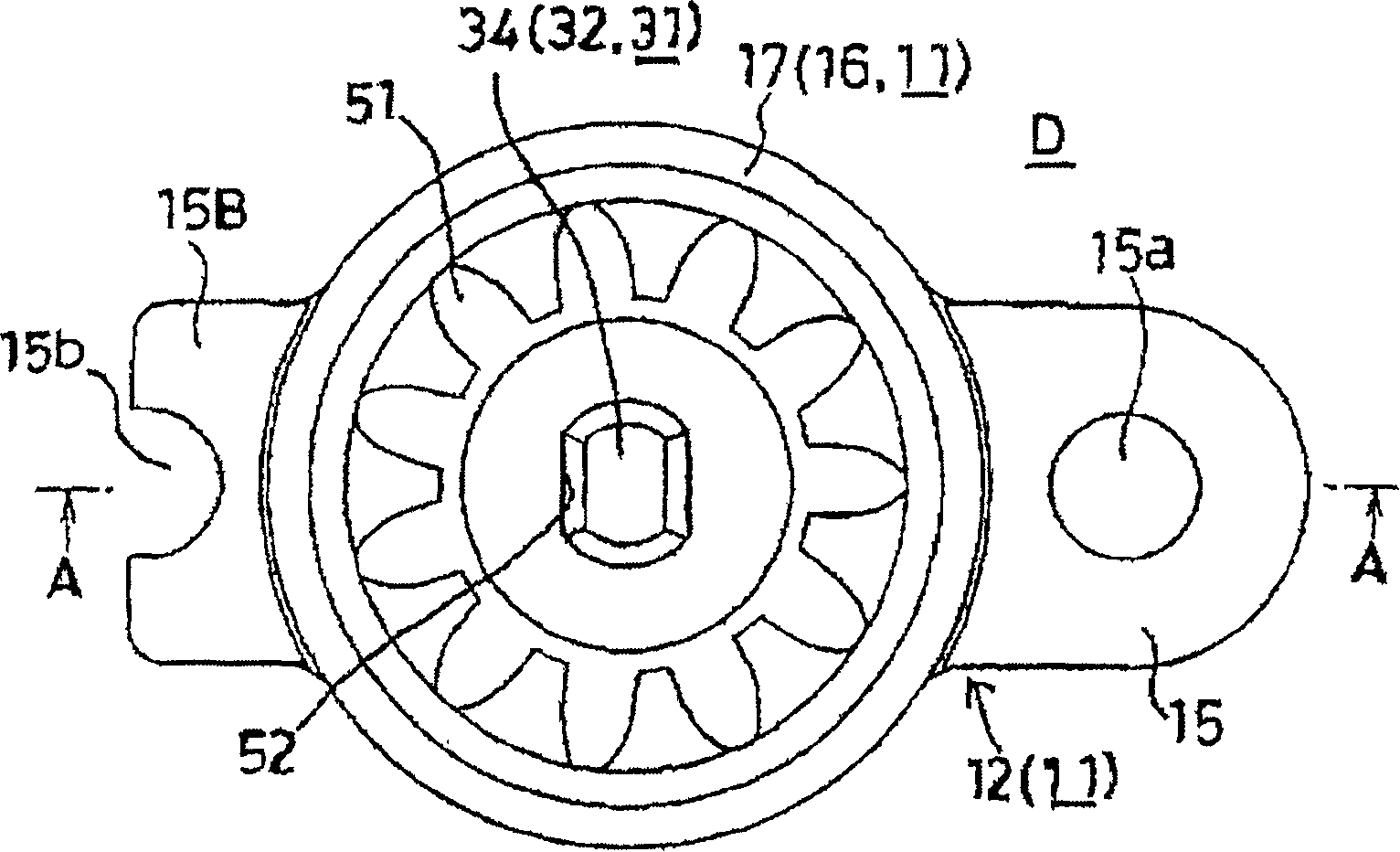

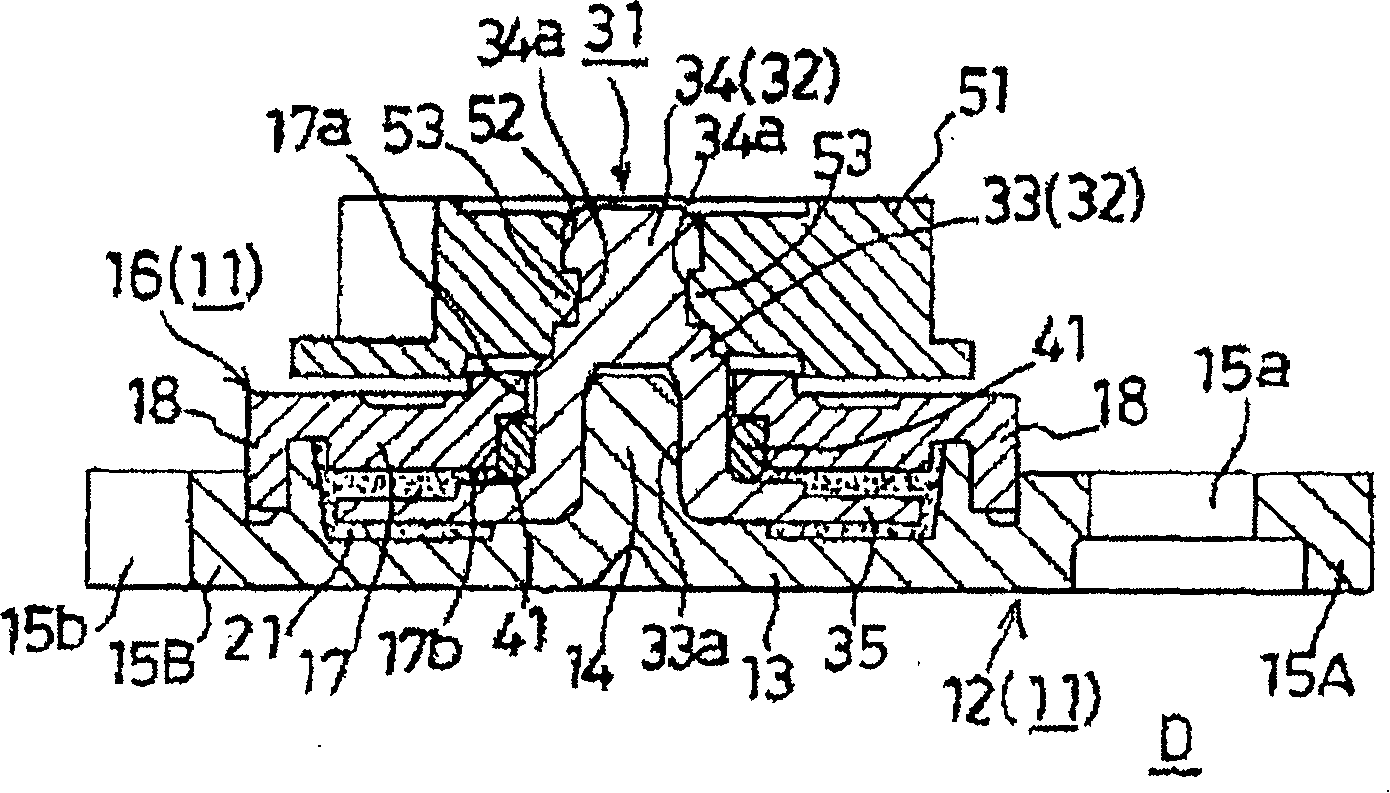

[0028] figure 1 is a plan view of a rotary damper as an embodiment of the present invention, figure 2 is along figure 1 Sectional view of line A-A.

[0029] In these figures, the composition of the rotary damper D includes: a casing 11; silicone oil 21 as a viscous fluid filled in the casing 11; a rotating shaft 32 having a part protruding from the casing 11; The rotor 31 of the rotor brake plate 35 is continuously arranged and rotatably accommodated in the housing 11; an O-ring as a sealing material is provided between the housing 11 and the rotating shaft 32 and prevents the silicon oil 21 from leaking out of the housing 11 41 ; the driven gear 51 installed on the portion of the rotating shaft 32 protruding from the housing 11 .

[0030] The housing 11 is composed of a housing main body 12 molded from synthetic resin and a cap 16 molded from synthetic resin.

[0031] M...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap