Passively rephasing piston

A piston and piston body technology, applied in the field of passive re-phasing pistons, can solve problems such as unsatisfied and achieve reliable re-phasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

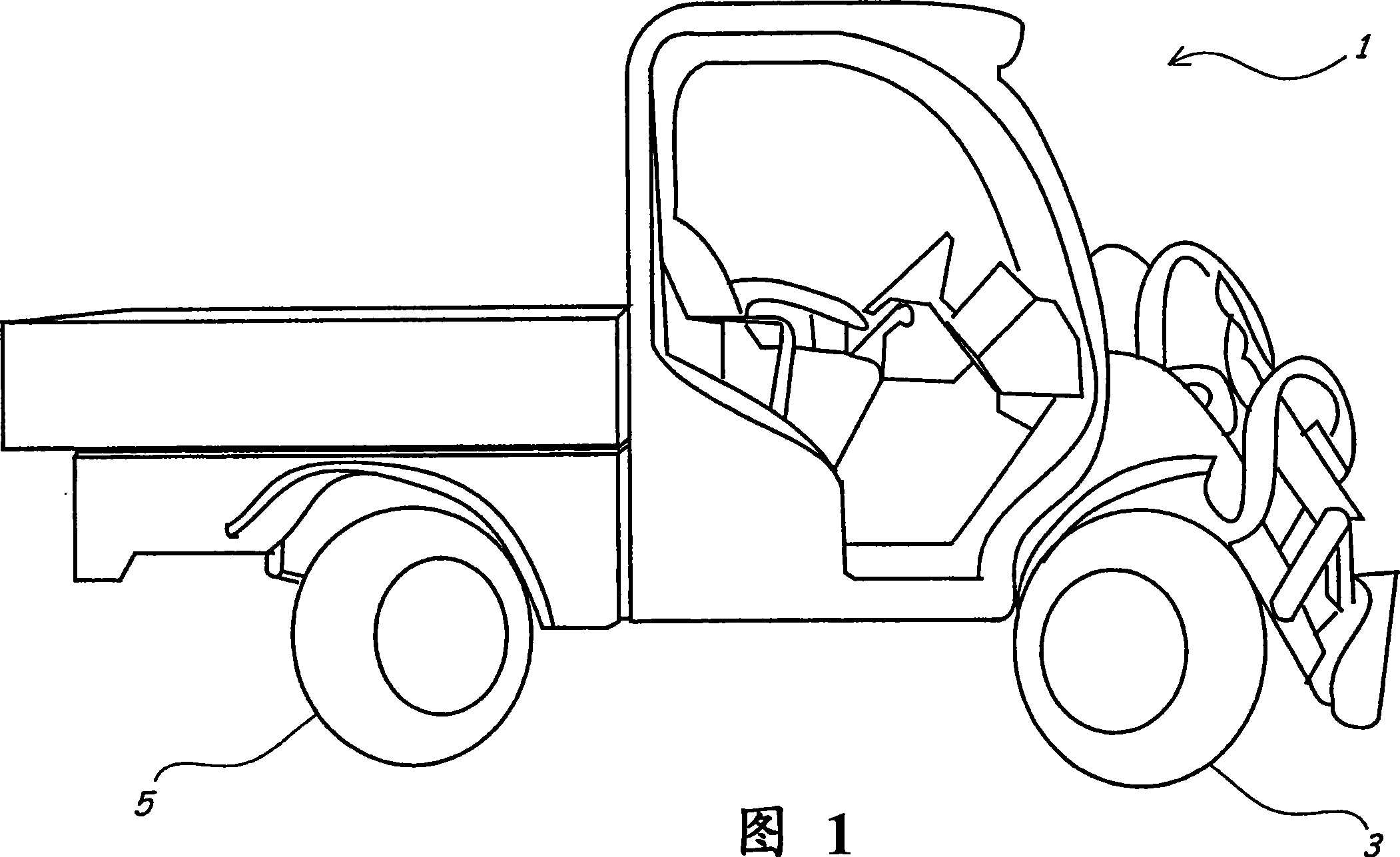

[0018] figure 1 A four wheel steerable vehicle 1 that may employ the fluid system of the present invention is described. The vehicle 1 comprises a pair of front steering wheels and a pair of rear steering wheels. The front steering wheel is controlled by the front rudder hydraulic cylinder, and one of the front steering wheels is wheel 3 as seen in the figure. The rear steering wheel is controlled by the rear rudder hydraulic cylinder, and one of the rear steering wheels is the visible wheel 5 among the figures. When controlling vehicle 1 to turn left, the front wheels will turn left while the rear wheels turn right. vice versa. Vehicle 1 is controlled to turn right, with the front wheels turning right and the rear wheels turning left. The four-wheel steering vehicle 1 has a smaller turning radius and other advantages compared with other vehicles that only use front or rear wheels for steering. The four wheel steer vehicle 1 is but one example of a wide variety of applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com