Light source module structure and light tube rack using the same

A technology of light source module and lamp tube, which is applied in the direction of light source fixation, optics, nonlinear optics, etc., and can solve problems such as difficult alignment between reflector and frame, deformation of frame and reflector, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In a preferred embodiment, the present invention provides a light source module structure capable of effectively fixing the reflector on the frame and the lamp tube frame used therein. In a preferred embodiment, the structure of the light source module is used for the backlight module in the display device. For example, display devices include household televisions, screens of personal computers and laptop computers, display screens of mobile phones and digital cameras, and the like. However, in different embodiments, this light source module structure can also be applied to kanban and other devices that require light sources.

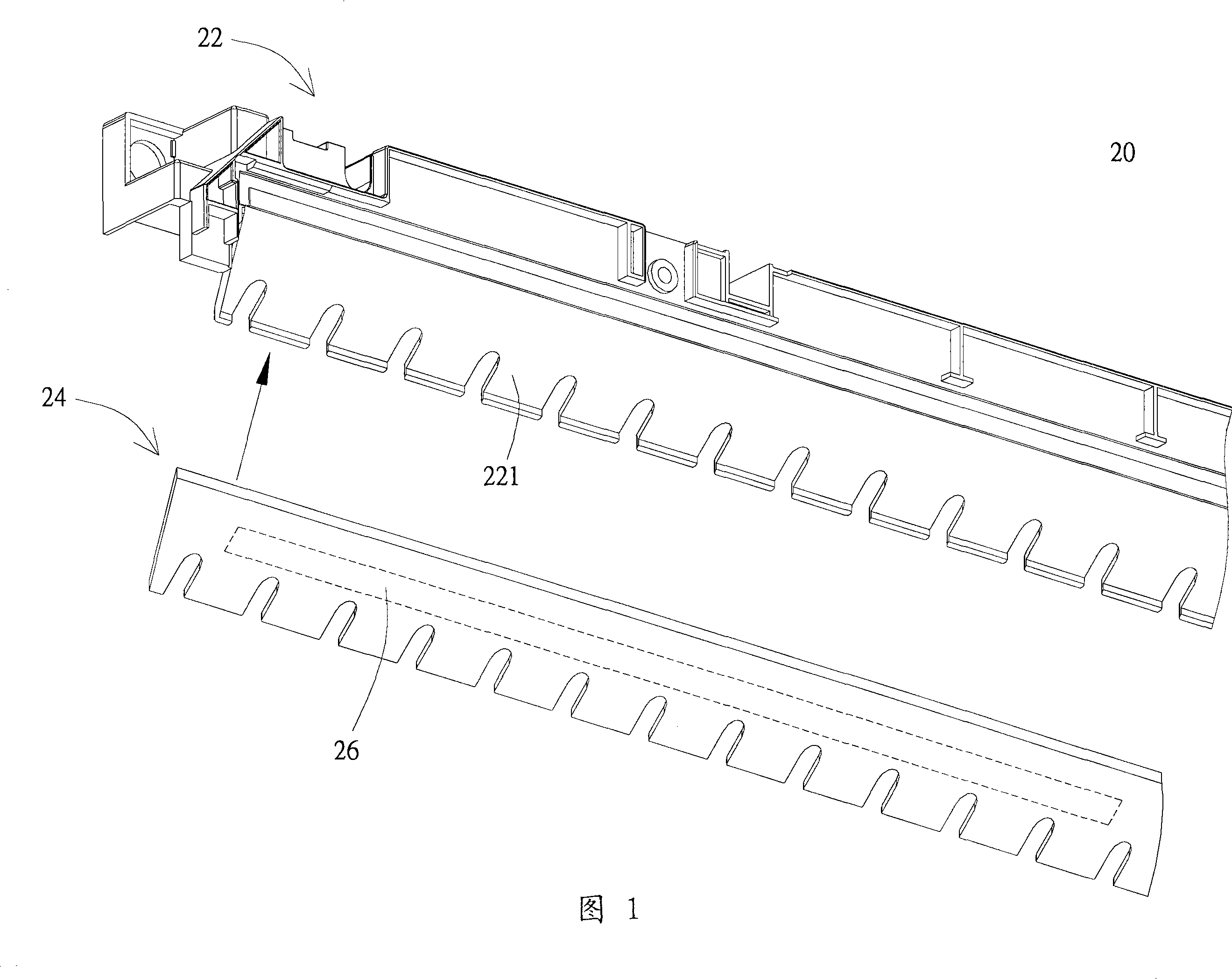

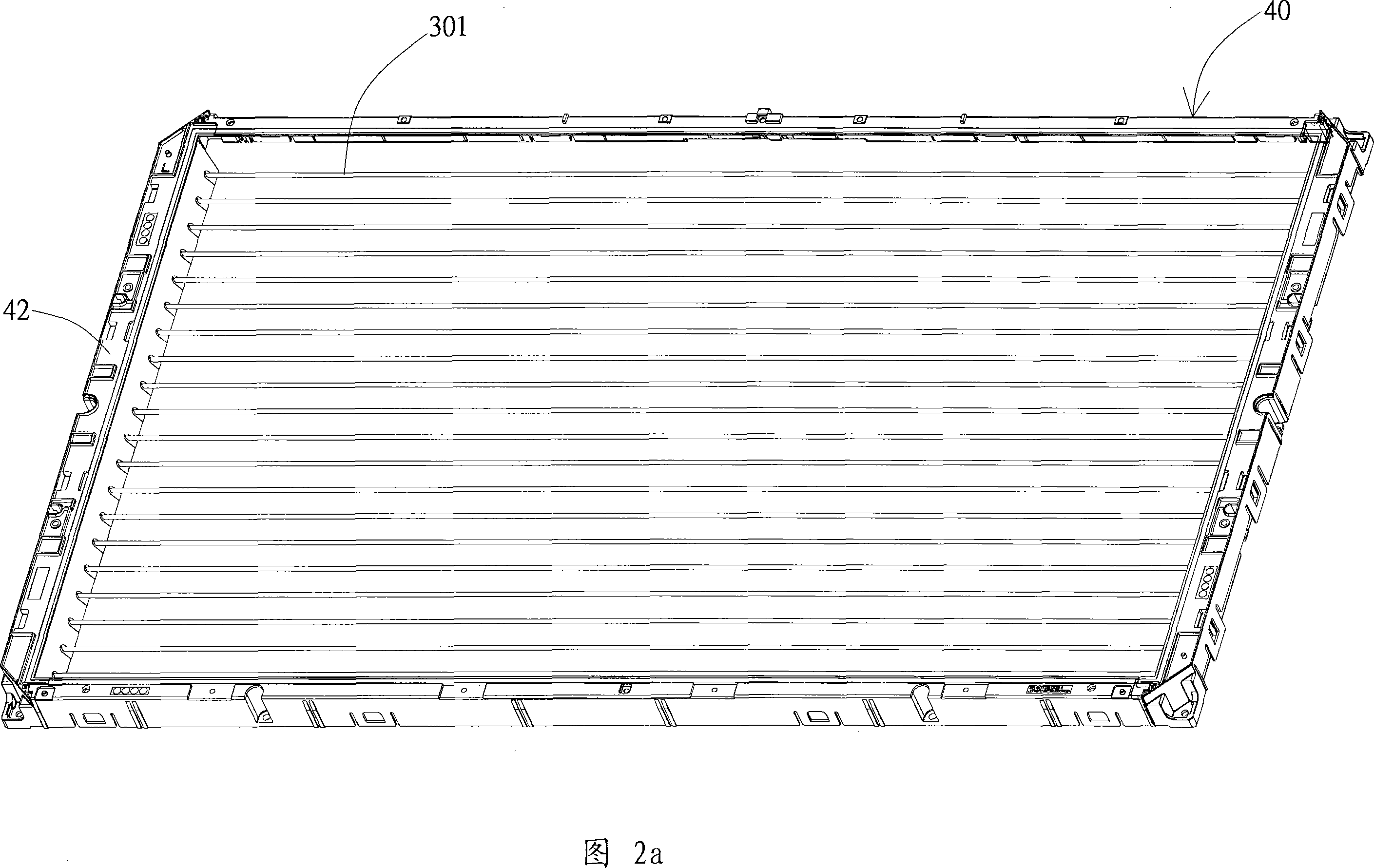

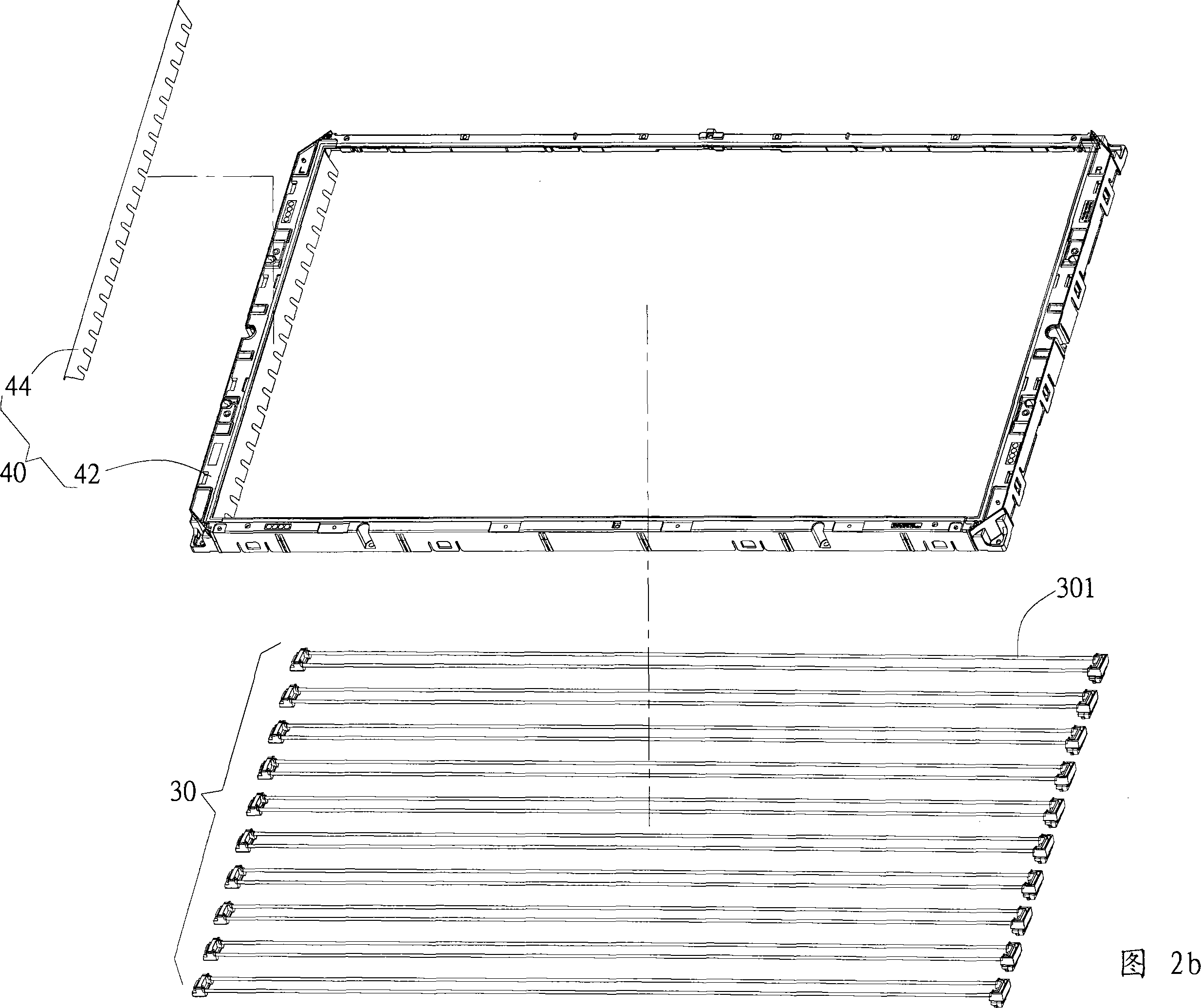

[0032] Fig. 2a is a schematic diagram showing the structure of a light source module according to an embodiment of the present invention. Figure 2b is an exploded view of Figure 2a. As shown in the figure, the light source module structure of this embodiment includes a light source module 30 and a lamp tube frame 40 . The lamp frame 40 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com