Mahjong and fabricating method thereof

A manufacturing method and mahjong technology, applied in sports accessories, indoor games and other directions, can solve the problems of uneven thermal expansion and cold contraction, monotonous and boring colors, etc., and achieve the effect of beautiful appearance, colorful colors, and avoidance of bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

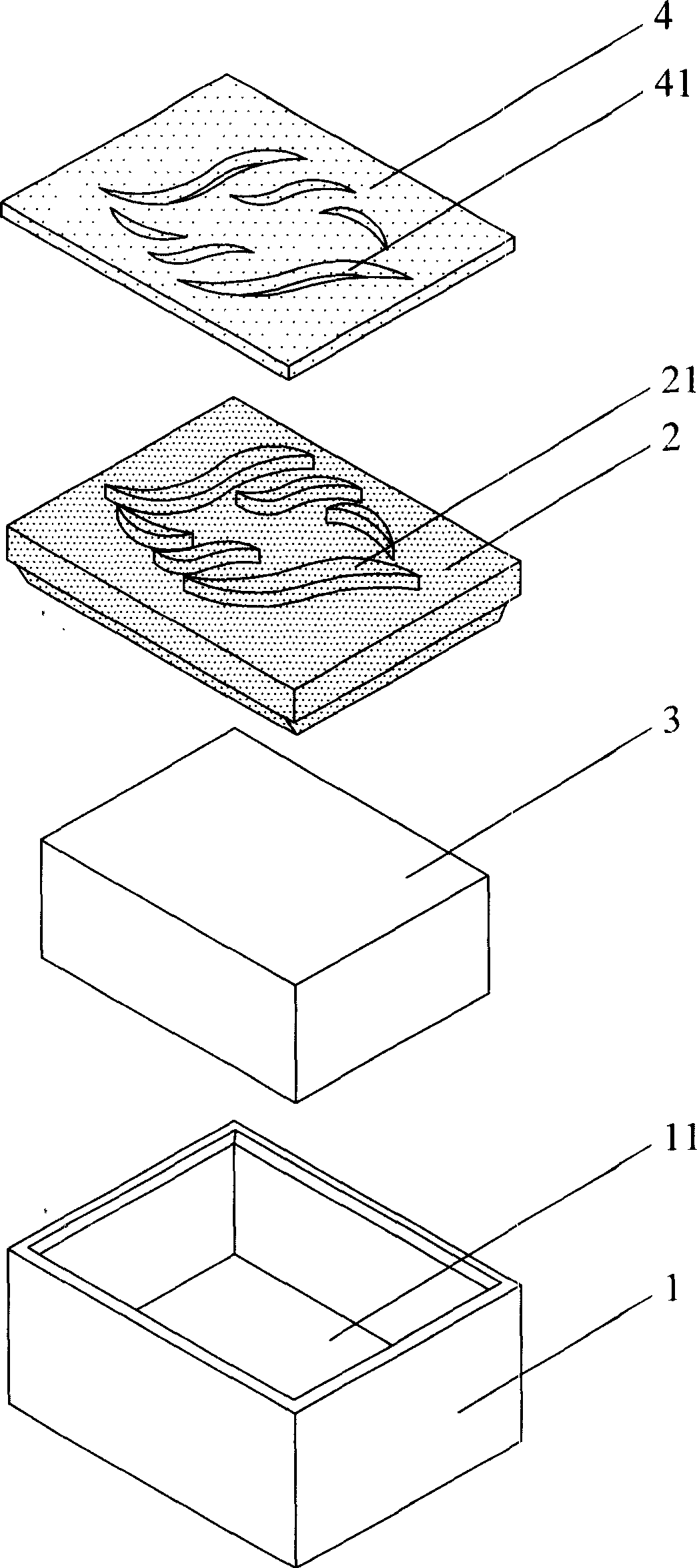

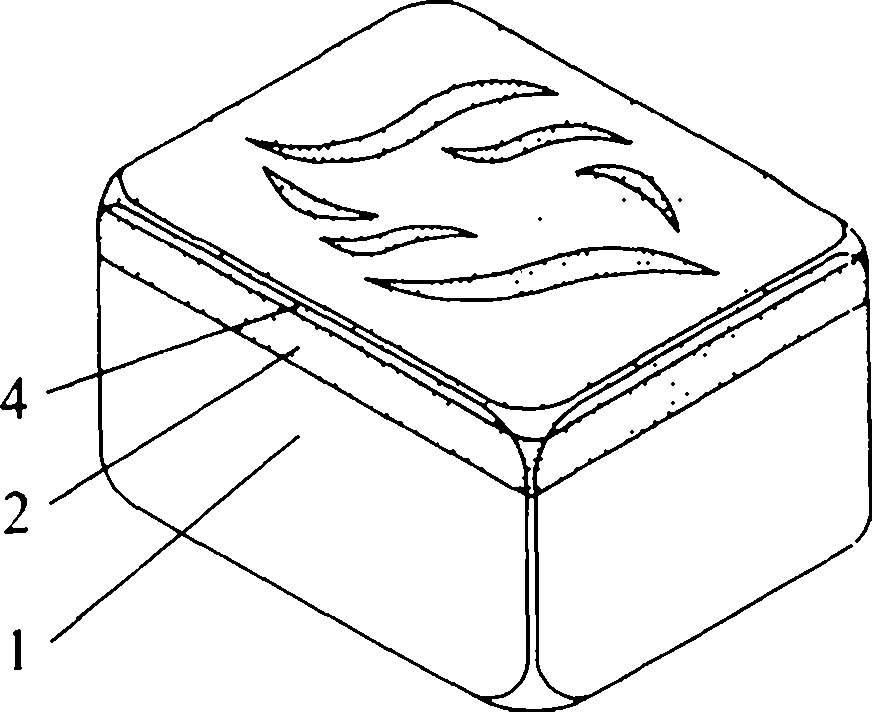

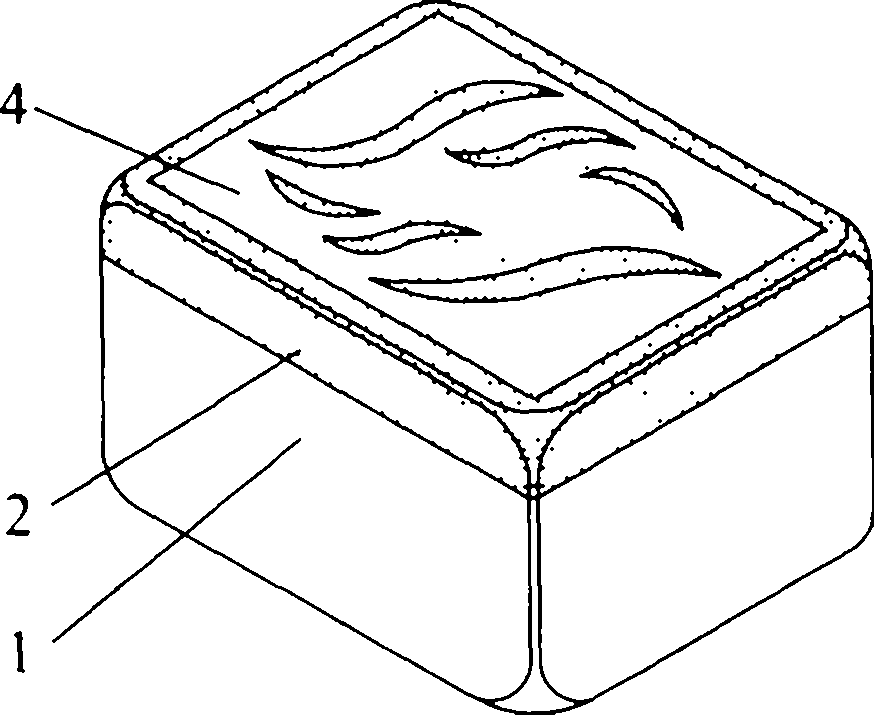

[0023] Mahjong of the present invention, as figure 1 As shown, it consists of a body layer 1 with a brand name on the front and a pattern layer 2 with a pattern on the back. The body layer 1 is provided with a cavity 11, and the cavity 11 is filled with a card core 3. The card core 3 is composed of the body layer 1 and the pattern. Layer 2 wrapping, wherein the pattern 21 of the card body pattern layer 2 protrudes outwards, the back of the card body is covered with a surface layer 4, and the surface layer 4 covers the periphery of the protruding pattern 21, that is, the surface layer 4 is formed with a pattern suitable for the protruding pattern 21. Matched through hole 41.

[0024] According to different designs, the thickness of the card body surface layer 4 can be equal to the protruding height of the card body pattern 21, so that the back of the mahjong is flush.

[0025] In order to increase the feel of the card body, the back of the mahjong can be designed in a concave-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com