Manufacturing device and method of polishing wheel

A manufacturing method and polishing wheel technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of polishing wheel imbalance, large vibration, low efficiency, etc., and achieve uniform spacing and simple and reasonable structure , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

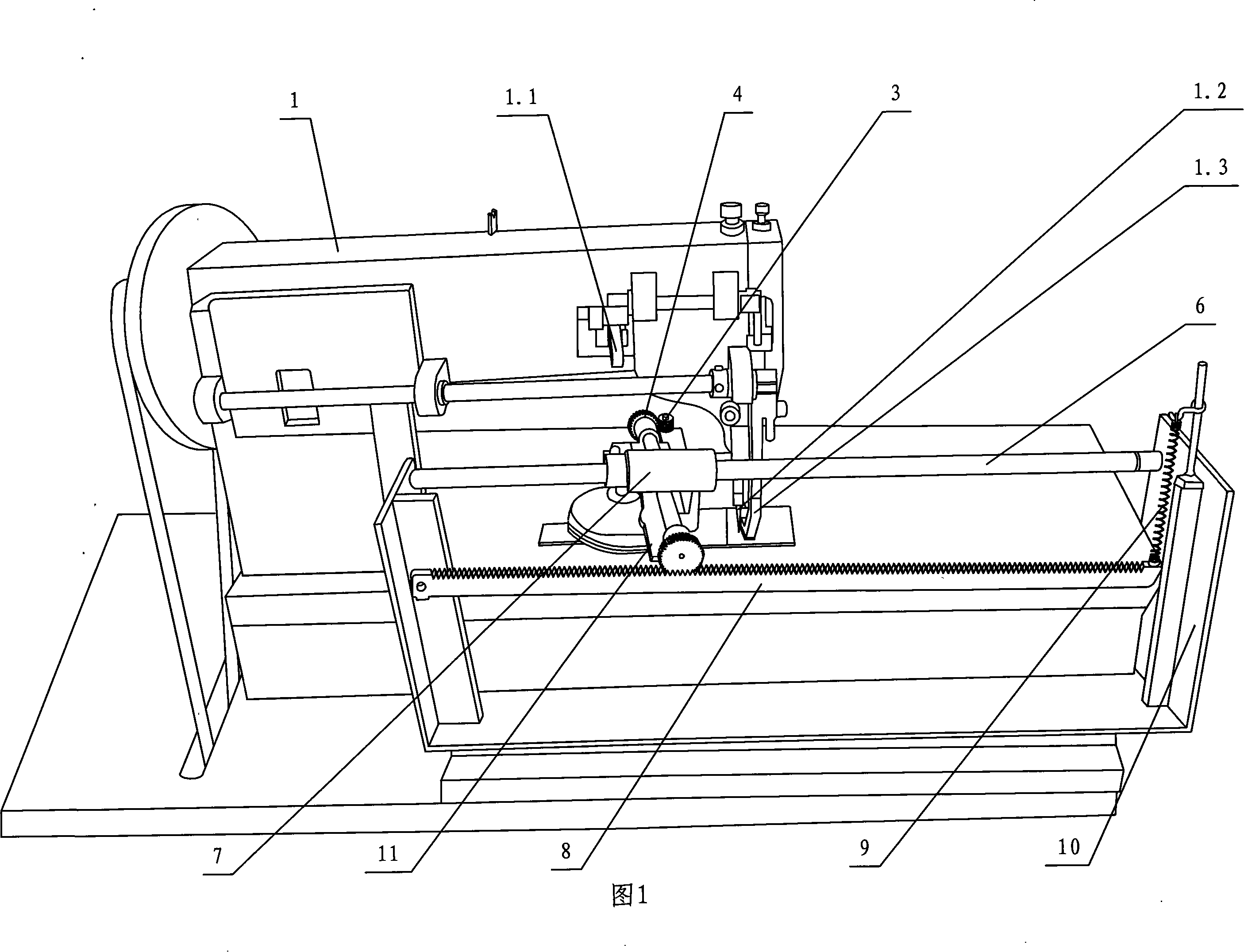

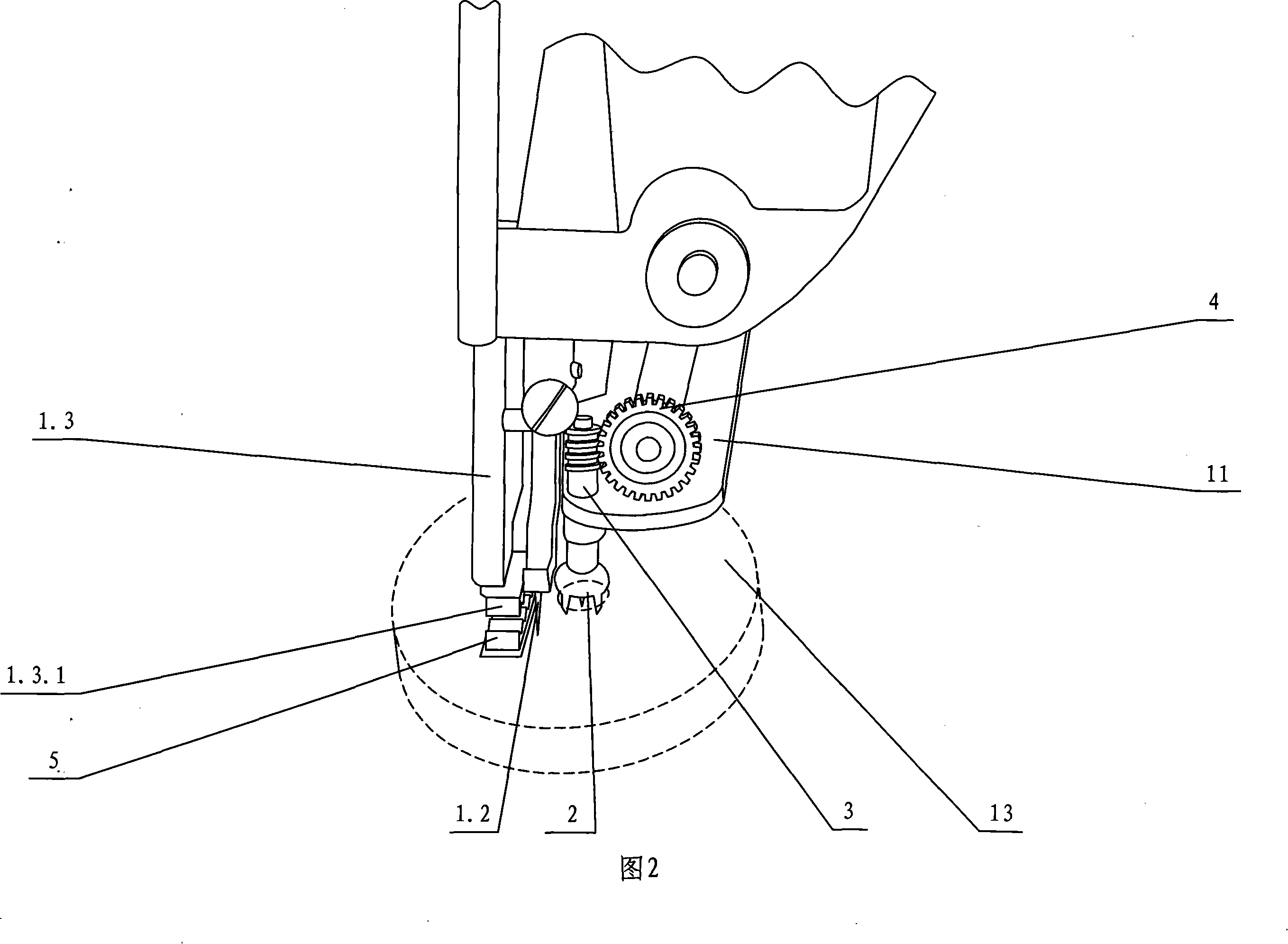

[0020] Referring to Fig. 1-Fig. 2, the manufacturing equipment of this buffing wheel comprises sewing machine 1 and buffing wheel driving mechanism, and this driving mechanism comprises claw 2, and its one end joins with the wheel core 13 center hole of buffing wheel, and the other end is connected with transmission One end of the rod 3 is connected, the other end of the transmission rod is meshed with one end of the worm wheel 4 through the worm, the other end of the worm wheel is meshed with the rack 8, the rack is set on the bracket 10, the bracket is set next to the sewing machine, and the transmission rod and the worm gear are respectively worn. On the mounting plate 11, the worm wheel 4 and the mounting plate 11 are crimped on the rack. The mounting plate 11 is connected to the guide rod 6 through the connecting sleeve 7 , and the guide rod is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com