Wound roll offset machine with changeable printing format

A technology of offset printing machine and format, applied in printing machine, rotary printing machine, lithographic rotary printing machine, etc., can solve the problems of increasing printing cost, incompatibility, increasing label printing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

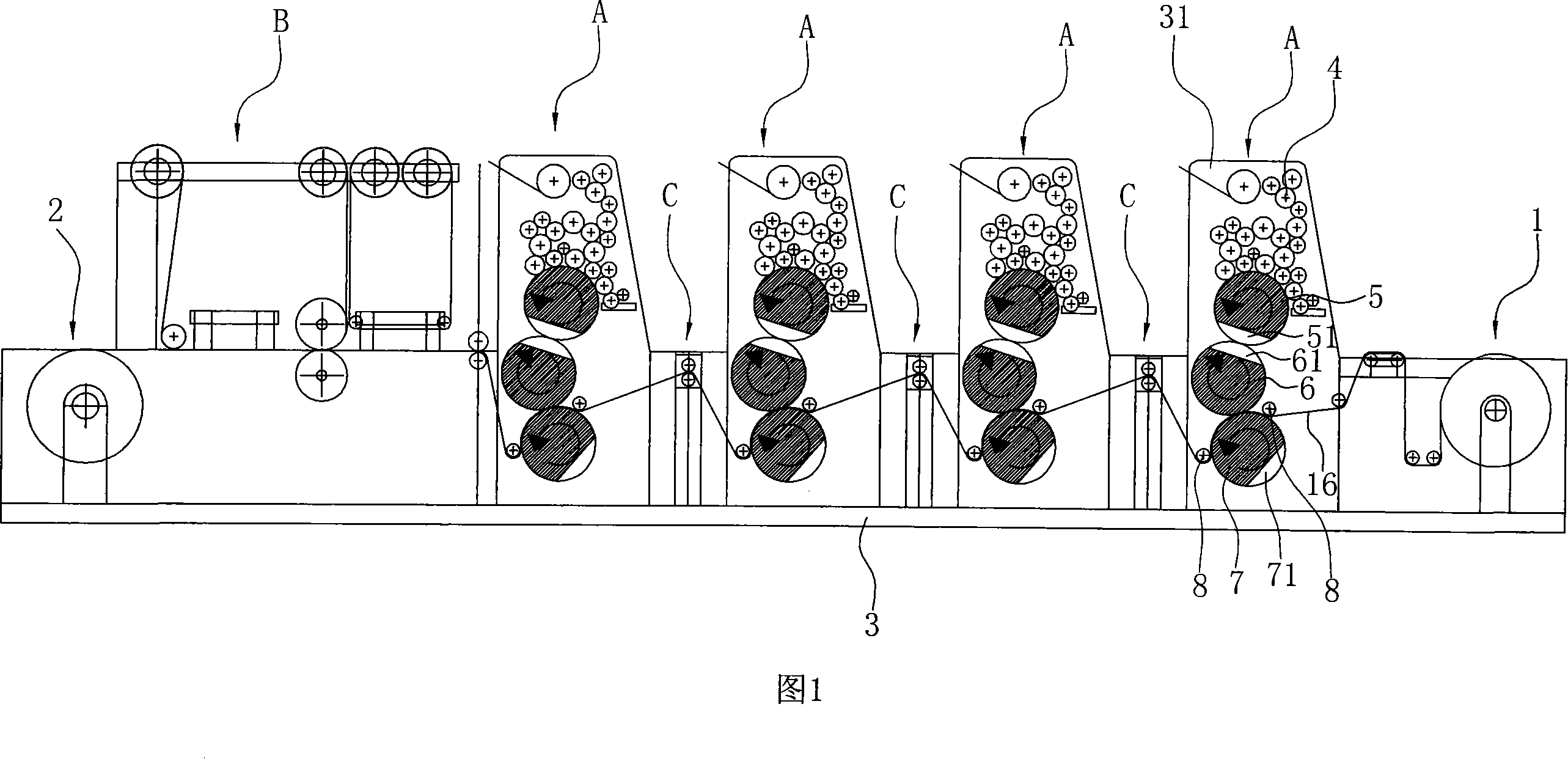

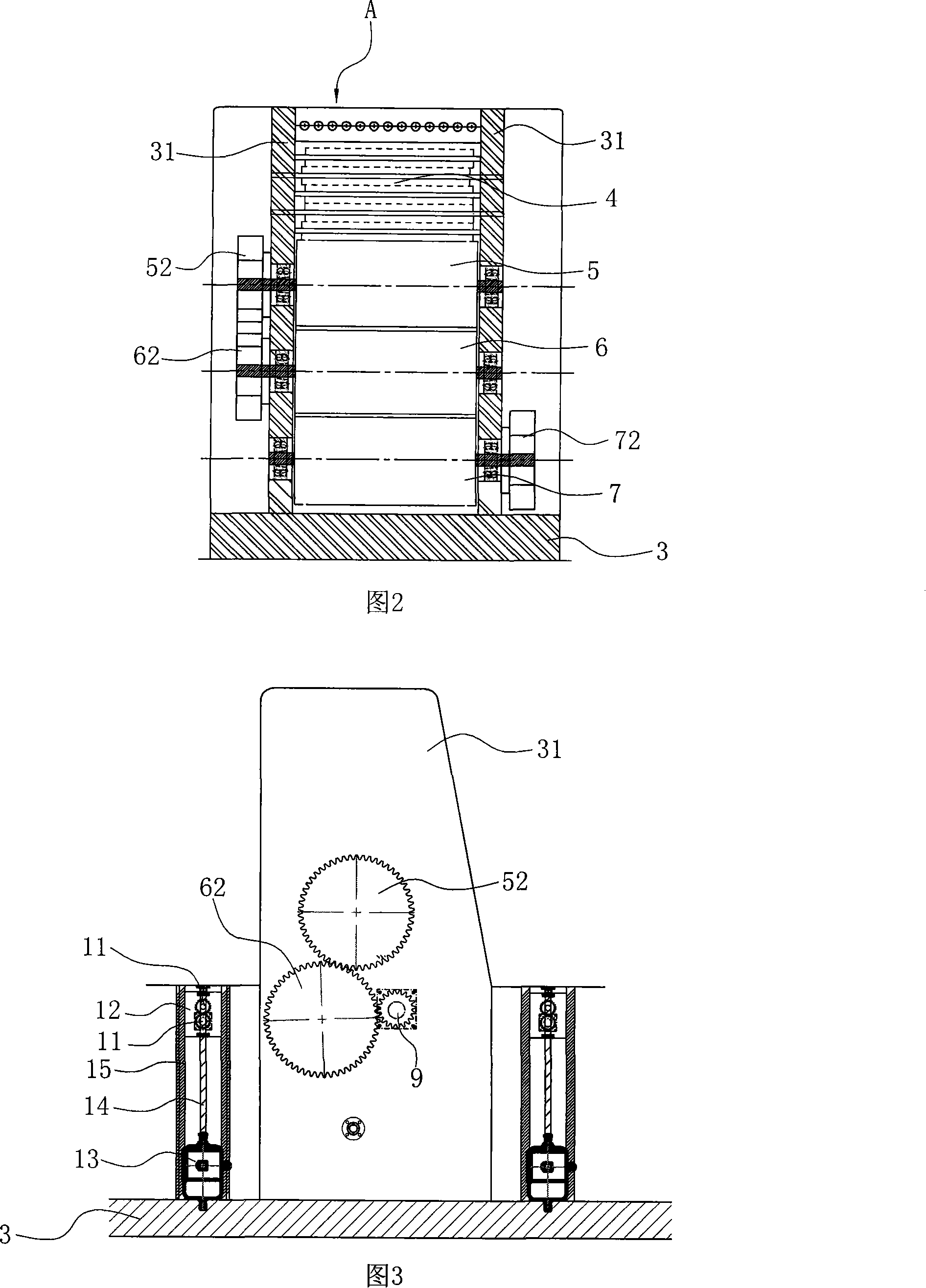

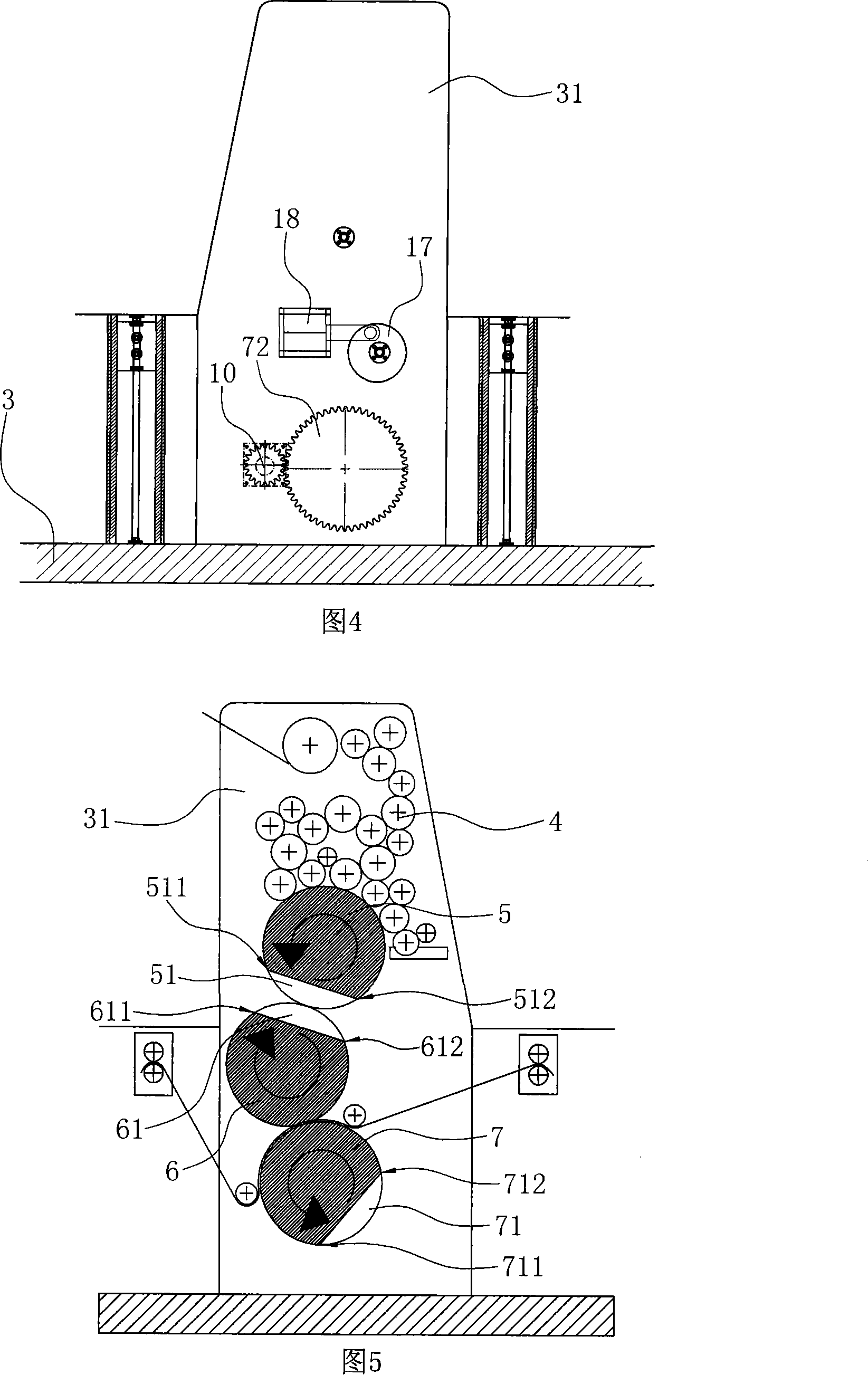

[0025] A preferred embodiment of the present invention is shown in Figures 1-6.

[0026] An offset printing machine that can change the printing format, mainly composed of a paper feeding mechanism 1, a paper delivery mechanism 2, four sets of printing units A, a frame 3, and a post-press processing mechanism B, and the post-press processing mechanism B is set in the last printing unit The rear part of A forms an assembly line, and the post-press processing mechanism B is an auxiliary mechanism. Among them, the paper feeding mechanism 1, the paper delivery mechanism 2, and the post-press processing mechanism B are conventional technologies, and the feeding mechanism used in various existing web offset printing machines can be adopted. The paper mechanism and the delivery mechanism will not be elaborated here.

[0027] The four groups of print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com