Backlight module and fixing structure thereof

A technology for fixing structures and backlight modules, which is applied in optics, nonlinear optics, lighting devices, etc., and can solve problems such as warping of optical sheets, inability to completely fix optical sheets, and glow lines on display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

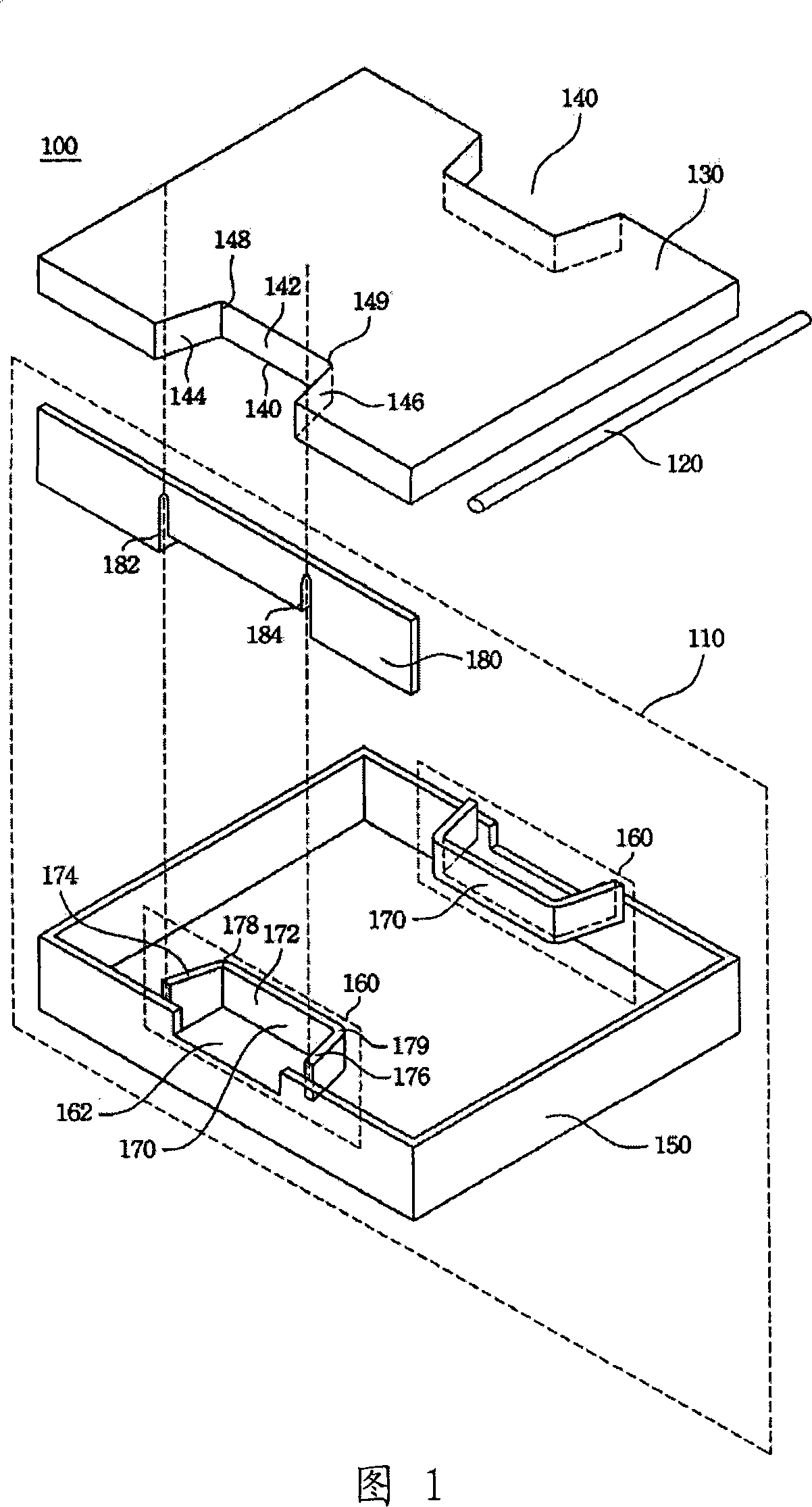

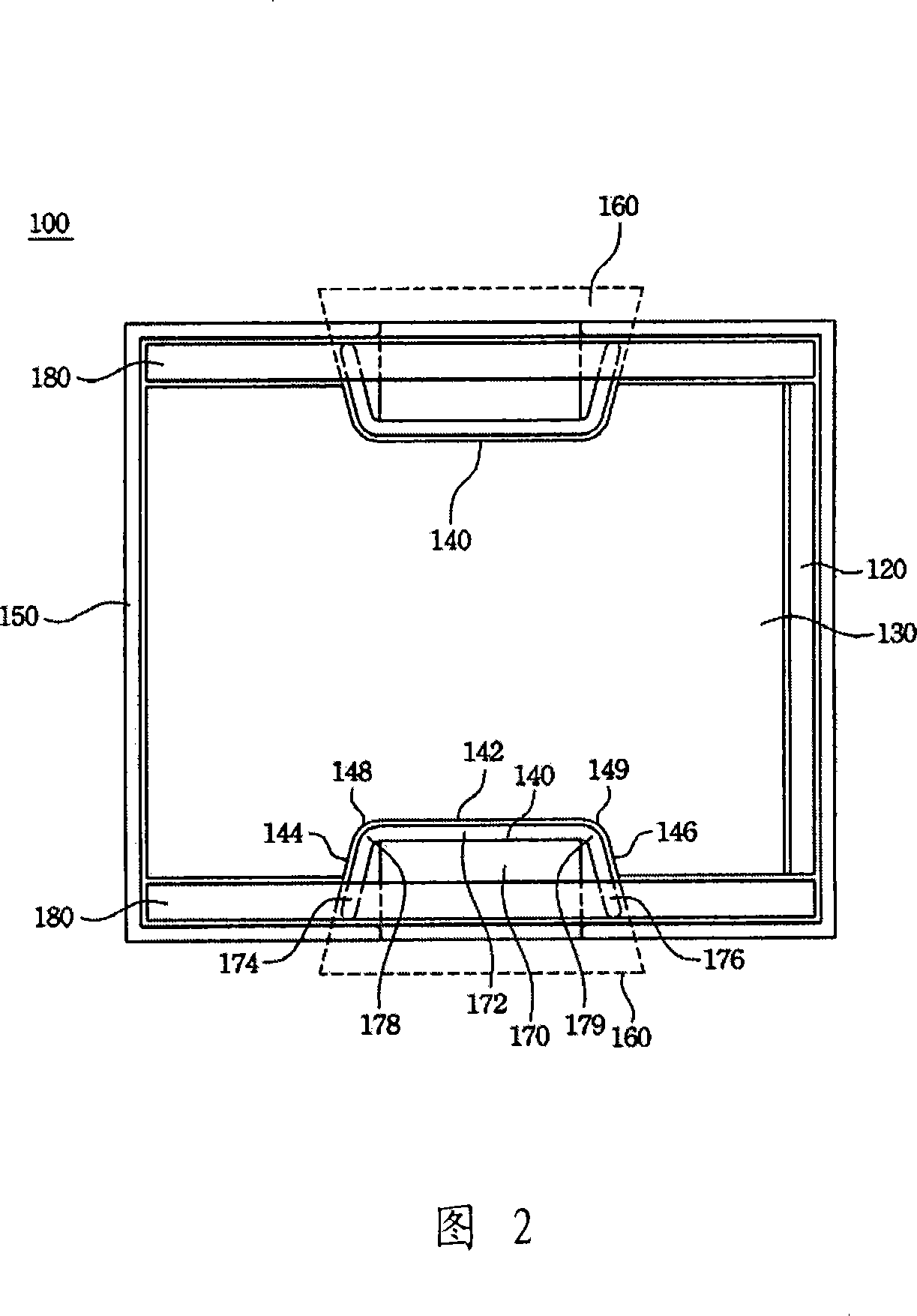

[0024] Please refer to FIG. 1 and FIG. 2 , which respectively illustrate an exploded view and a top view of a backlight module 100 according to an embodiment of the present invention. The backlight module 100 is used to supply uniform light to the liquid crystal display panel, and includes a light source 120 , a light guide plate 130 and a fixing structure 110 . The function of the light guide plate 130 is to guide the light from the light source 120 so that the light is evenly transmitted to the liquid crystal display panel. There is a groove 140 on the side of the light guide plate 130 , which cooperates with the fixing structure 110 to fix the light guide plate 130 .

[0025] The fixing structure 110 includes a frame 150 for accommodating the light guide plate 130 and the light source 120 . The frame 150 is connected to the positioning structure 160 and can engage the groove 140 so that the light guide plate 130 is fixed in the frame 150 , thereby fixing the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com