Apparatus and method for measuring optical system parameter

A technology of measuring device and optical system, which is applied in the direction of measuring device, adopting optical device, exposure device of photographic plate-making process, etc., can solve problems such as inability to measure, achieve error elimination, high measurement accuracy, and improve the effect of eccentricity measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

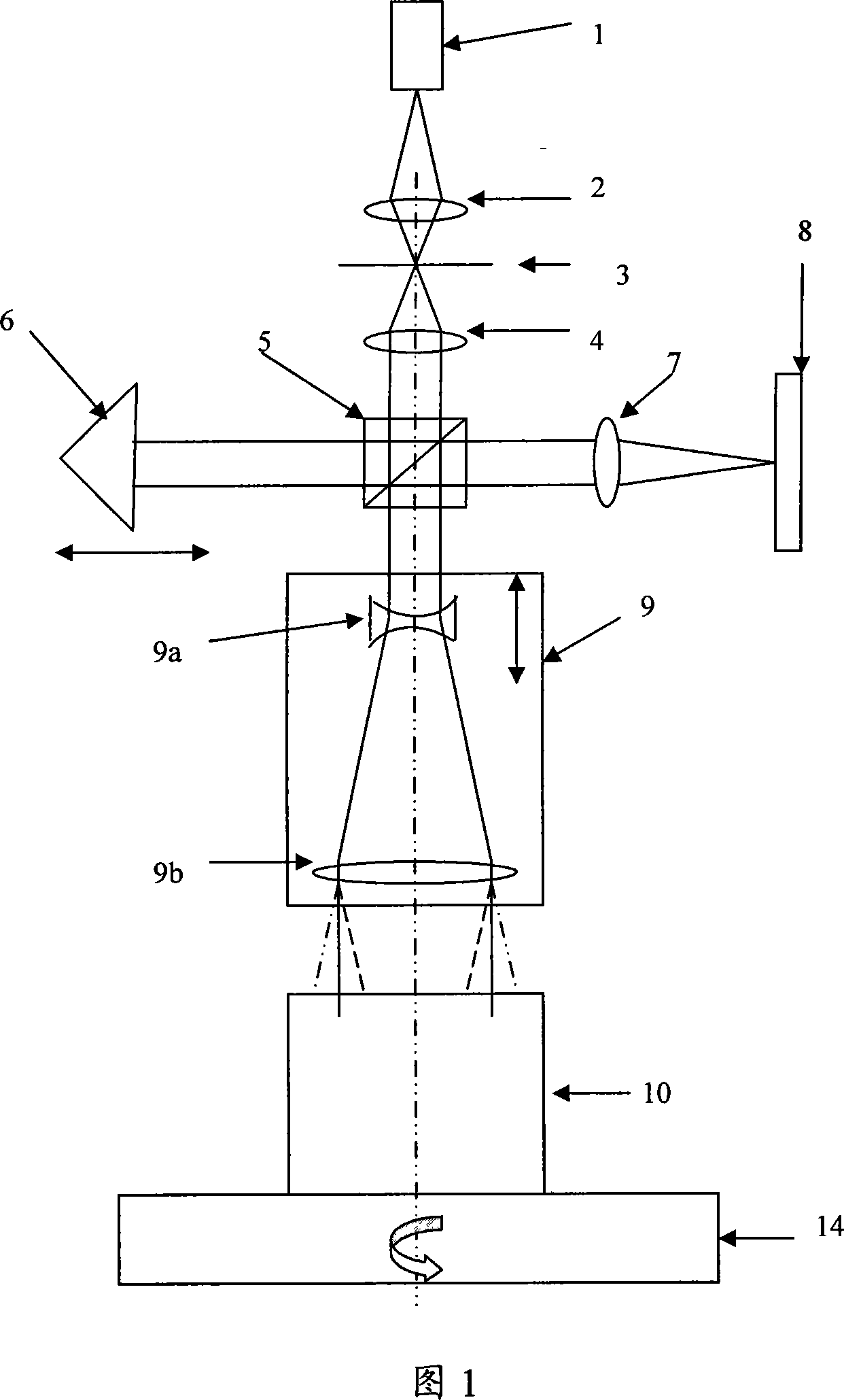

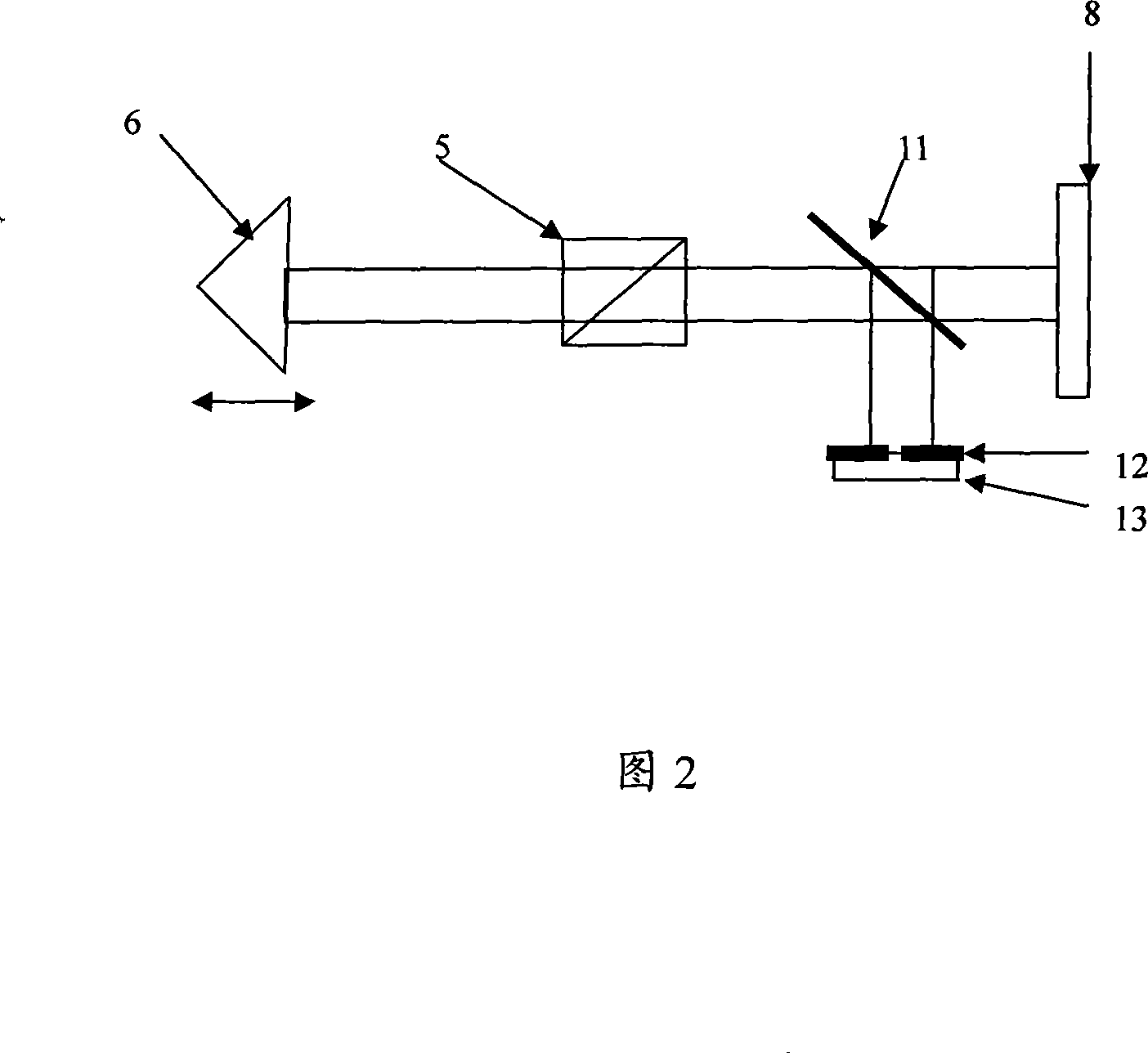

[0054] As shown in Figure 1, the present invention provides a kind of measuring device for measuring optical system parameters, comprising:

[0055] Light source 1, described light source 1 is short-coherent light source, usually adopts short coherence length light-emitting diode (LED), and it has good spatial coherence and poor time coherence shape, and coherence length is about 20um;

[0056] The focusing mirror 2 is located under the light source 1;

[0057] The pinhole 3 is located at the lower focal length of the focusing mirror 2;

[0058] The collimating lens 4 is located below the pinhole 3, and the collimating lens has a good ability to eliminate spherical aberration;

[0059] The beam splitter 5 is located below the collimating lens 4;

[0060] The one-dimensional mobile stage (not shown in the figure) is horizontally arranged on one side of the beam splitter 5, and is jointly composed of mechanical coarse displacement and PZT (piezoelectric ceramics) fine displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com