Insulation type general use illumination LED driving circuit

An LED driving and isolated technology, applied in the electronic field, can solve the problems of large peak voltage, poor reliability of non-isolated LED driving circuit, low power utilization rate of LED driving circuit, etc., to save peripheral circuits, small size, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

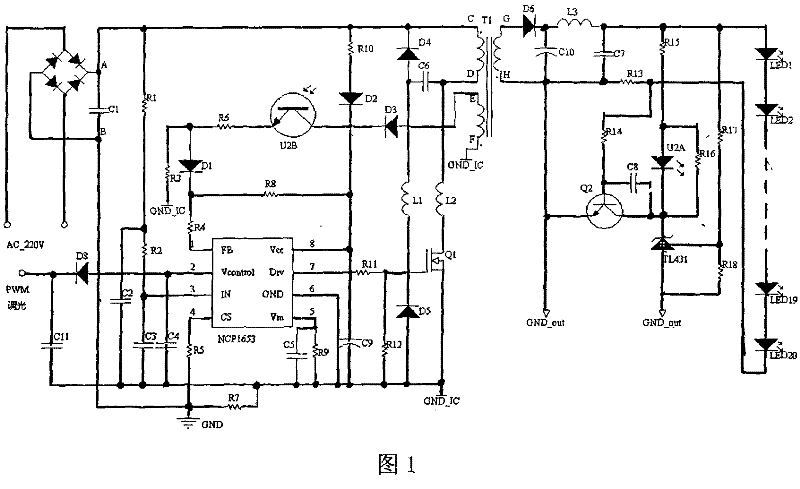

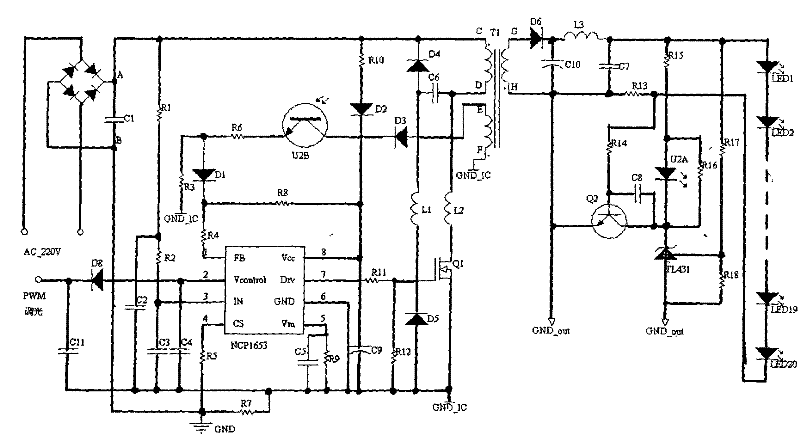

[0017] As shown in Figure 2, the circuit is mainly composed of NCP1653, isolated switching transformer T1, surge absorbing circuit (diode D4, D5, capacitor C6, inductor L1, L2), optocoupler isolator (U2A, U2B) and resistors, capacitors, NCP1653 The CS pin (the 4th pin) detects the current of the branch to change the pulse width to realize PFC. The diode D4, D4, D5, inductor L1, and capacitor C6 absorb the peak voltage generated at the moment the switch tube is turned off, and the inductor L2 absorbs The inrush current generated at the moment the switch tube is turned on, the FB pin (the first pin) of the NCP1653 detects the feedback signal of the optocoupler isolator to realize the output overcurrent and LED open circuit protection functions, the V of the NCP1653 control The pin (the second pin) is connected to the PWM control signal through the diode D8 to realize the LED dimming function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com