Crimping machine for different crimping and pressing processes, in particular for cable assembly

A technology of crimping tools and cables, applied in the direction of line/collector parts, connections, electrical components, etc., which can solve the problems of orientation and fixation, the impact of device operation quality, and the unrestricted supply of contact materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

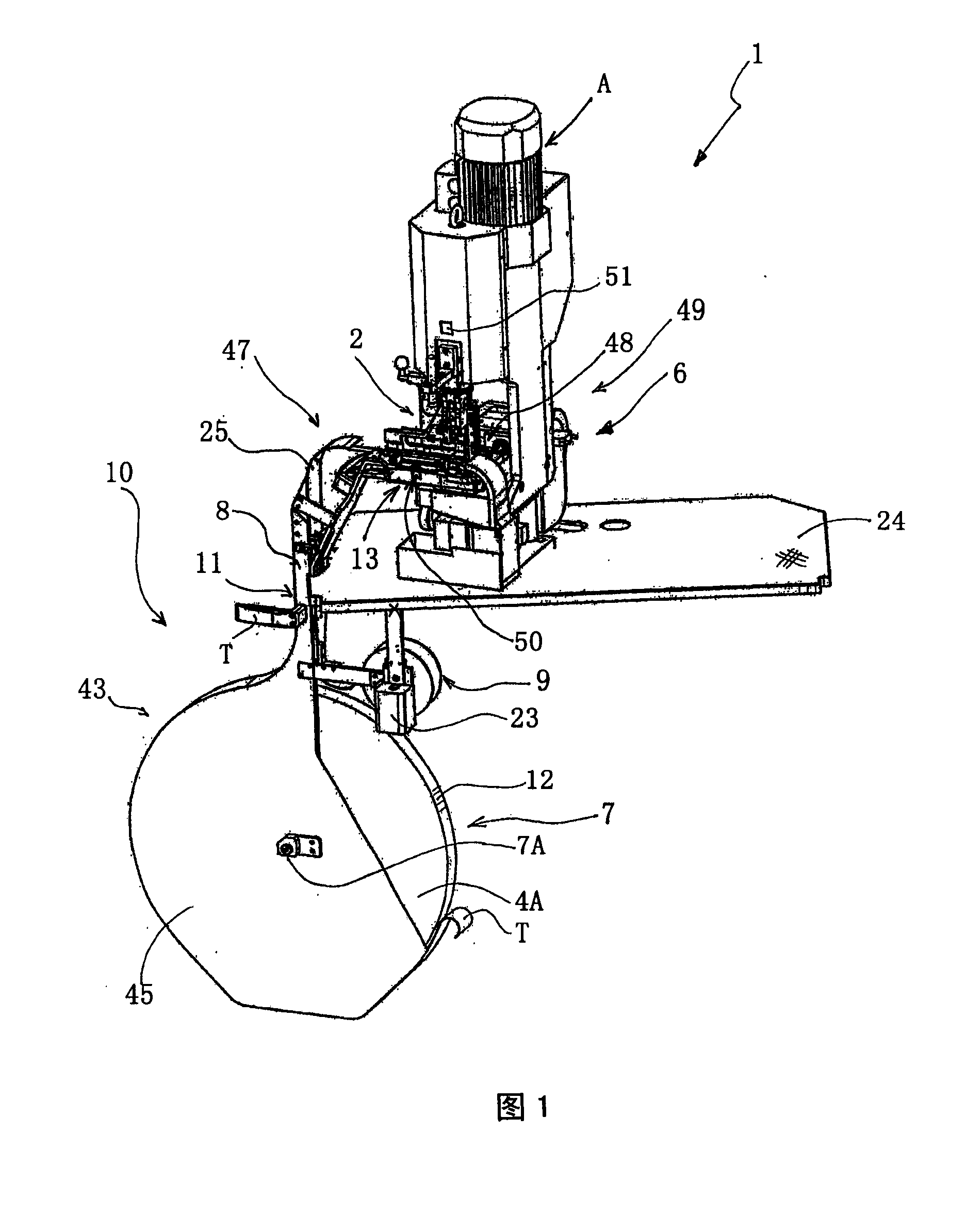

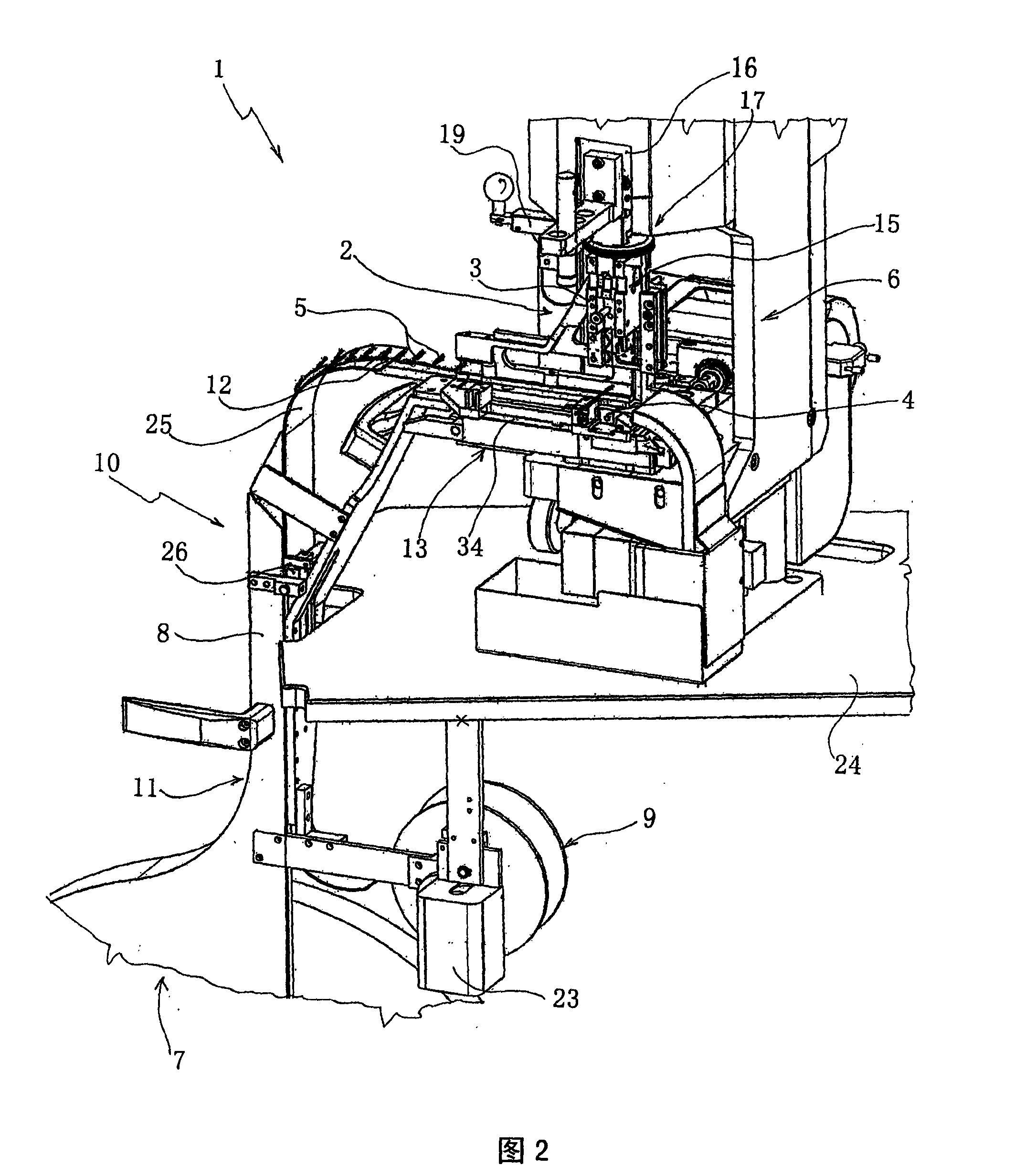

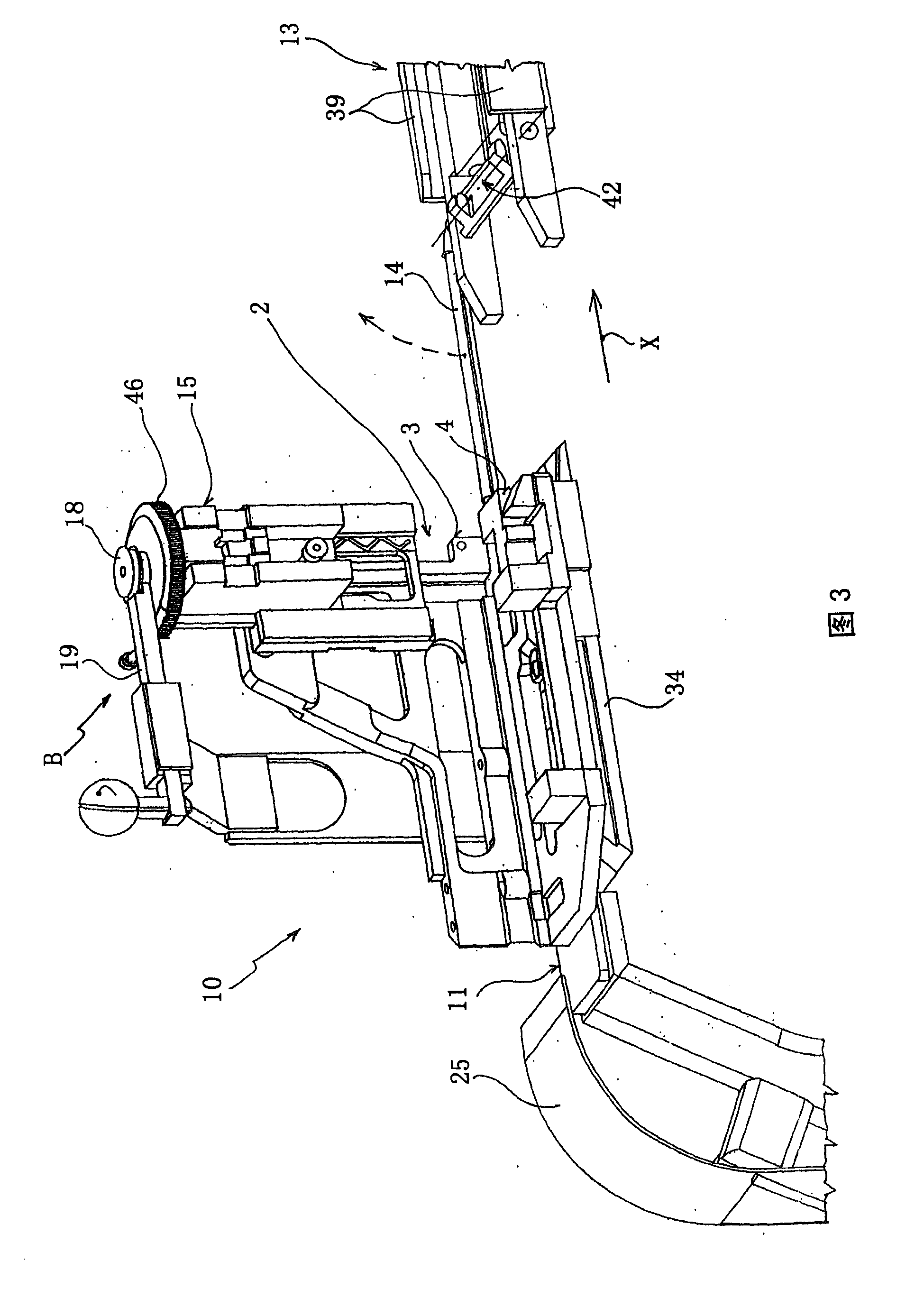

[0079] Figures 1 and 2 show a working example of a crimping machine 1 according to the invention provided with a transverse contact supply 47 (the known supply of cables with strip-shaped ends is not shown). This crimping machine 1 can be used for different crimping and pressing processes, such as cable assemblies, and is provided with a two-part crimping tool 2 and a tool holder 48 and a movable upper tool 3 of the crimping tool 2, by which relative movement , "crimping", ie pressing, the crimping contact 5, which can be placed onto the fixed lower tool 4 of the crimping tool 2, with the end of the electrical conductor for producing the crimping bond.

[0080] The crimping machine 1 has a crimping station 6 provided with a crimping tool 2, a tool holder 48, a drive unit A and a contact supply 47 (the crimping tool 2 with its drive unit A and the tool holder 48 form a so-called "crimp press"). For example, such a crimping tool 2 is commercially available under the name "UNI-A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap