Curing spray printing combination

A combined device and top spray technology, applied in the directions of spray device, spray device, printing, etc., can solve the problems of cumbersome equipment operation and control, affecting rolling rhythm, poor temperature adaptability, etc., and achieve simple and reliable equipment maintenance and printing rhythm. The effect of shortening and reducing the repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

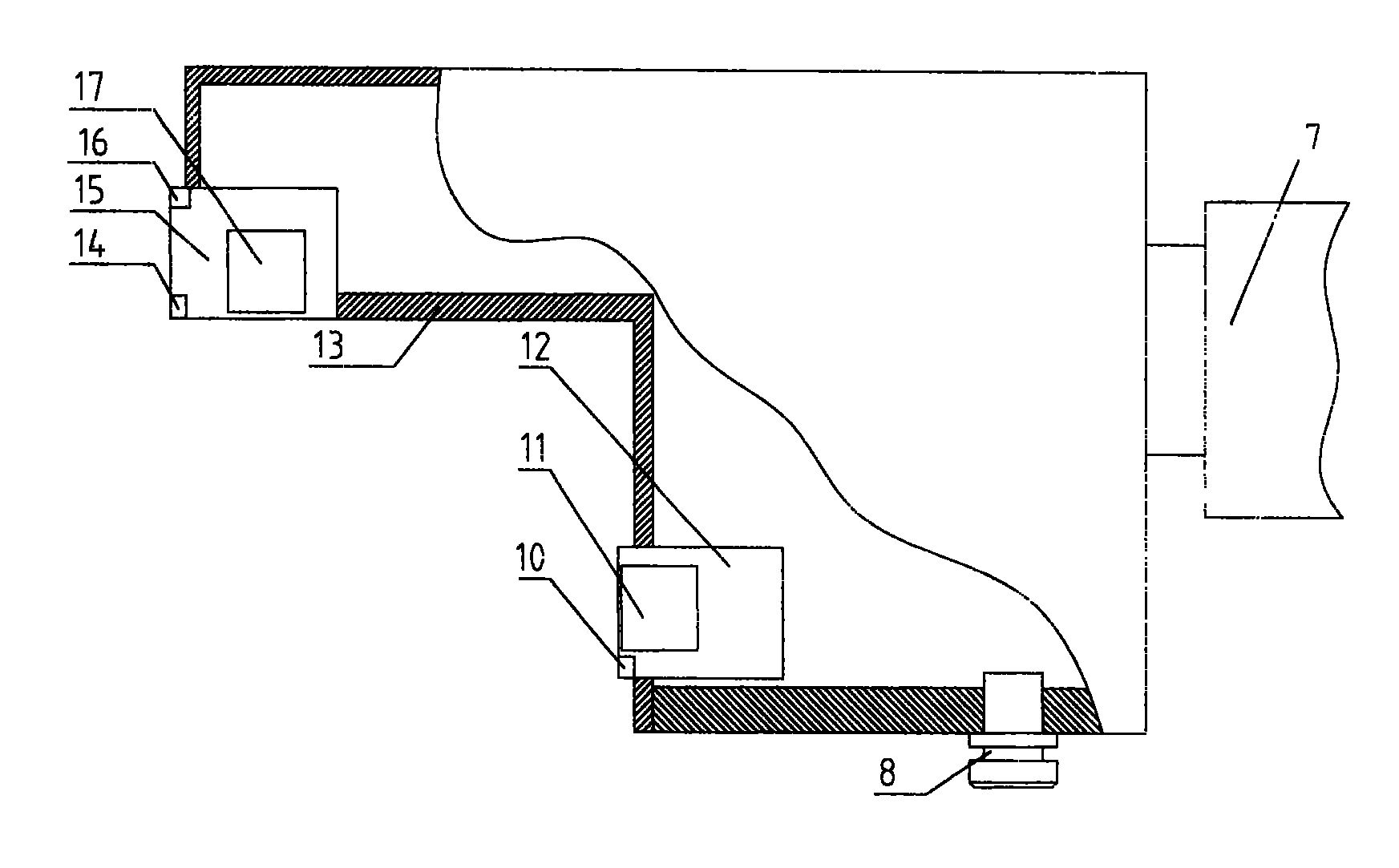

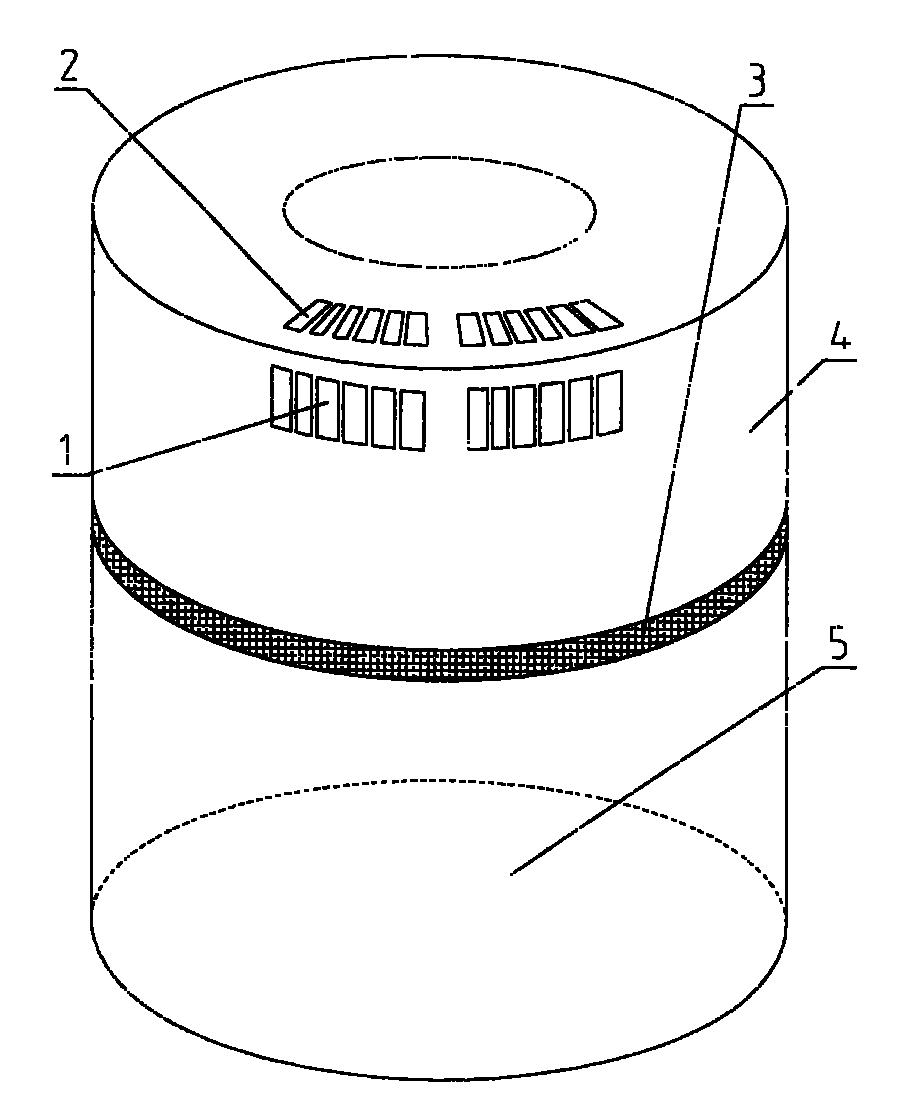

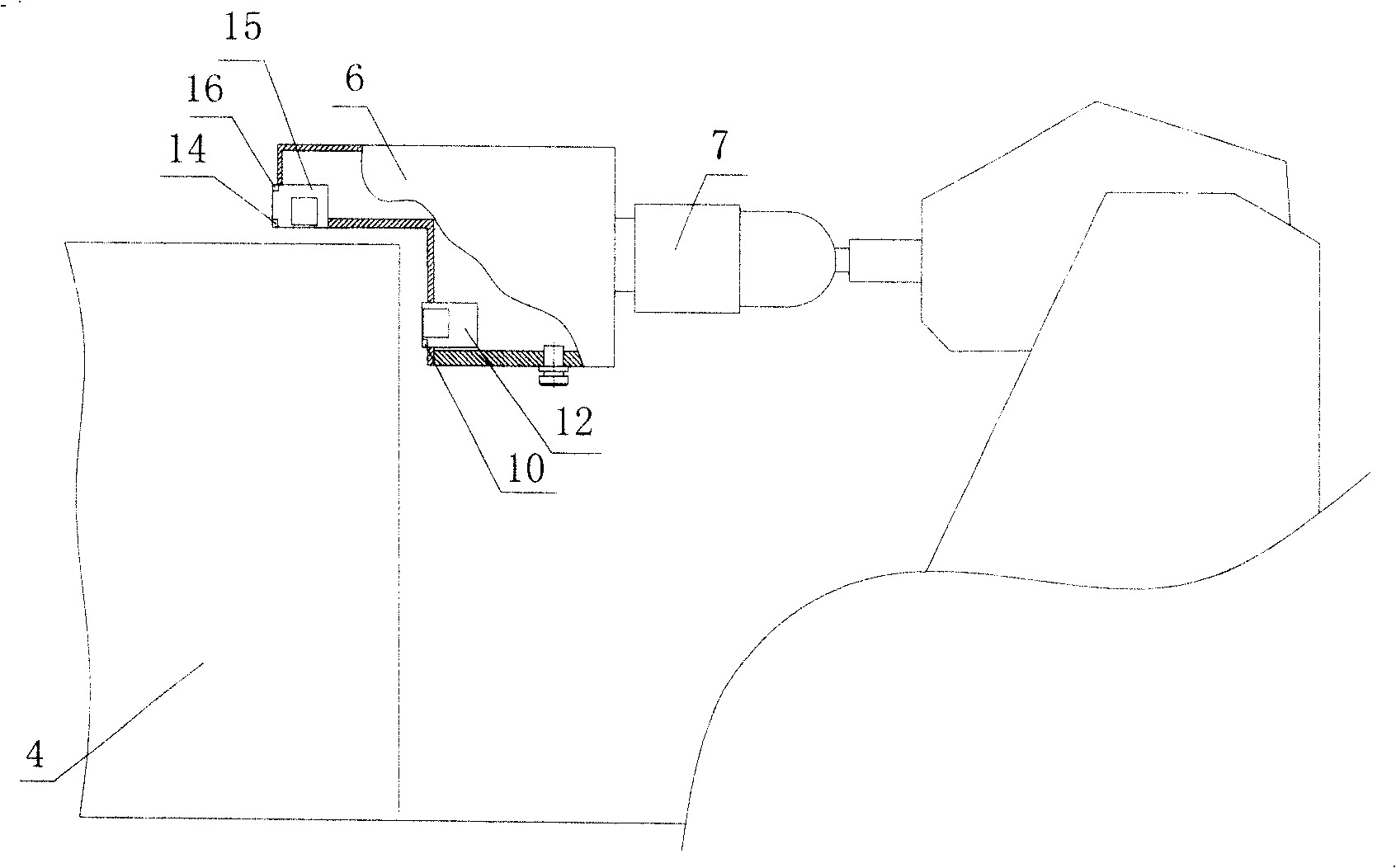

[0025] As shown in Figure 3, it is the first embodiment of the curing jet printing combination device of the present invention. In this embodiment, the top spray assembly 15 and the side spray assembly 12 are connected at right angles in a box body 13, and the box body 13 is connected and installed on the arm. 7 on.

[0026] As shown in Figure 4, it is the second embodiment of the curing jet printing combination device of the present invention. In this embodiment, the top spray assembly 15 and the side spray assembly 12 are respectively installed in a separate box body 9 and a box body 19. The box body 9 and the box body 19 are connected together at right angles through the connecting plate 18, and the connecting plate 18 is then connected and fixedly installed on the arm 7.

[0027] In the two embodiments, the horizontal distance and the longitudinal distance between the top spray assembly 15 and the side spray assembly 12 are all adjustable, that is, the top spray assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com