Spacer for reducing concrete usage of construction slab

A technology of concrete and usage, which is applied in the direction of floors, buildings, building components, etc., and can solve the problems of negative effects that are easily transmitted to the lower floors, and the reduction of negative concrete usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the present invention will be described in detail below with reference to the drawings.

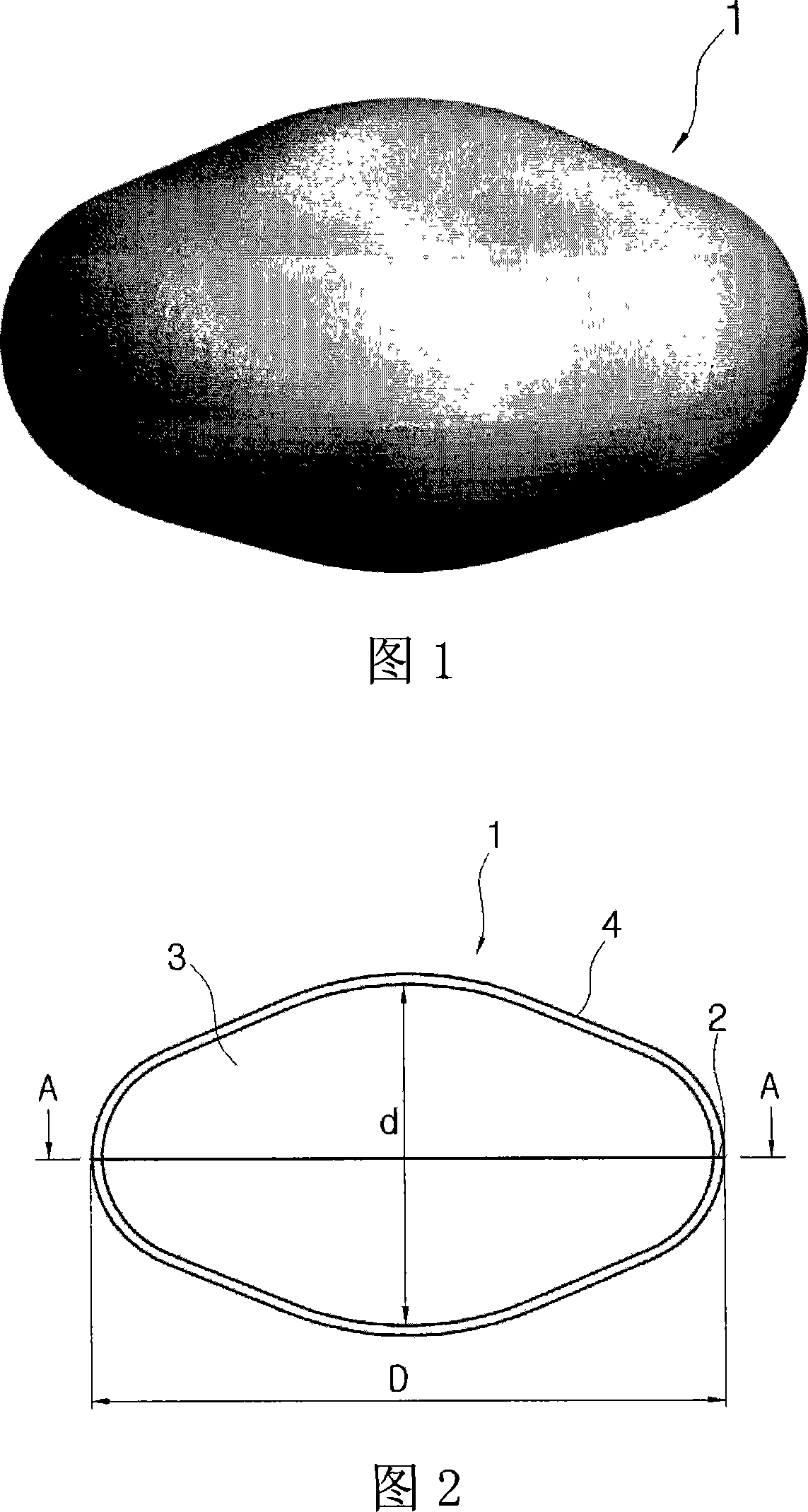

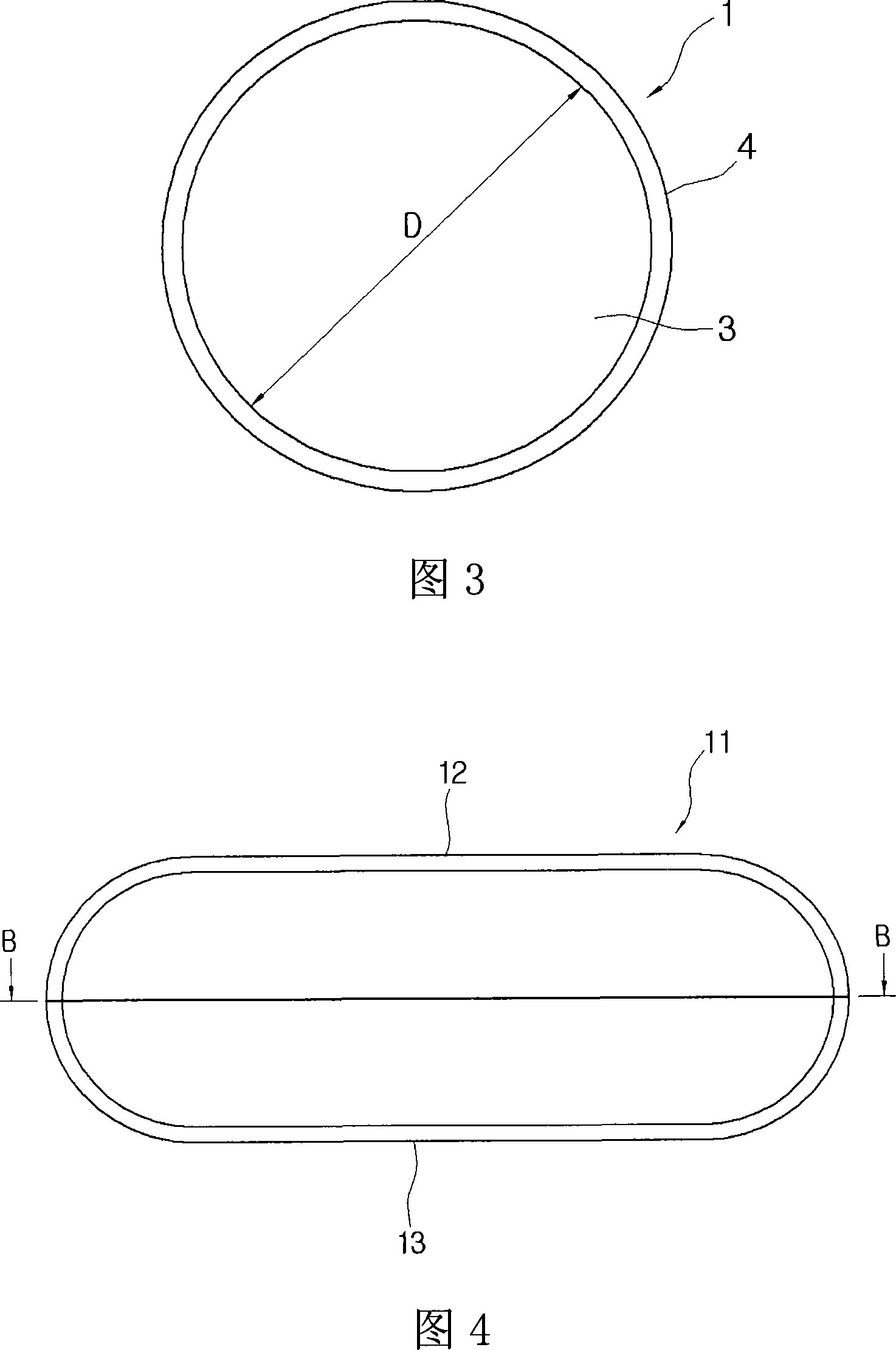

[0024] Fig. 1 is a side view of an embodiment of the cushion block of the present invention, Fig. 2 is a front cross-sectional view of an embodiment of the cushion block of the present invention, Fig. 3 is an AA horizontal cross-sectional view of the same cushion block, and Fig. 4 is a cushion block of the present invention A front cross-sectional view of another embodiment. FIG. 5 is a BB horizontal cross-sectional view of the spacer block shown in the embodiment of FIG. 4.

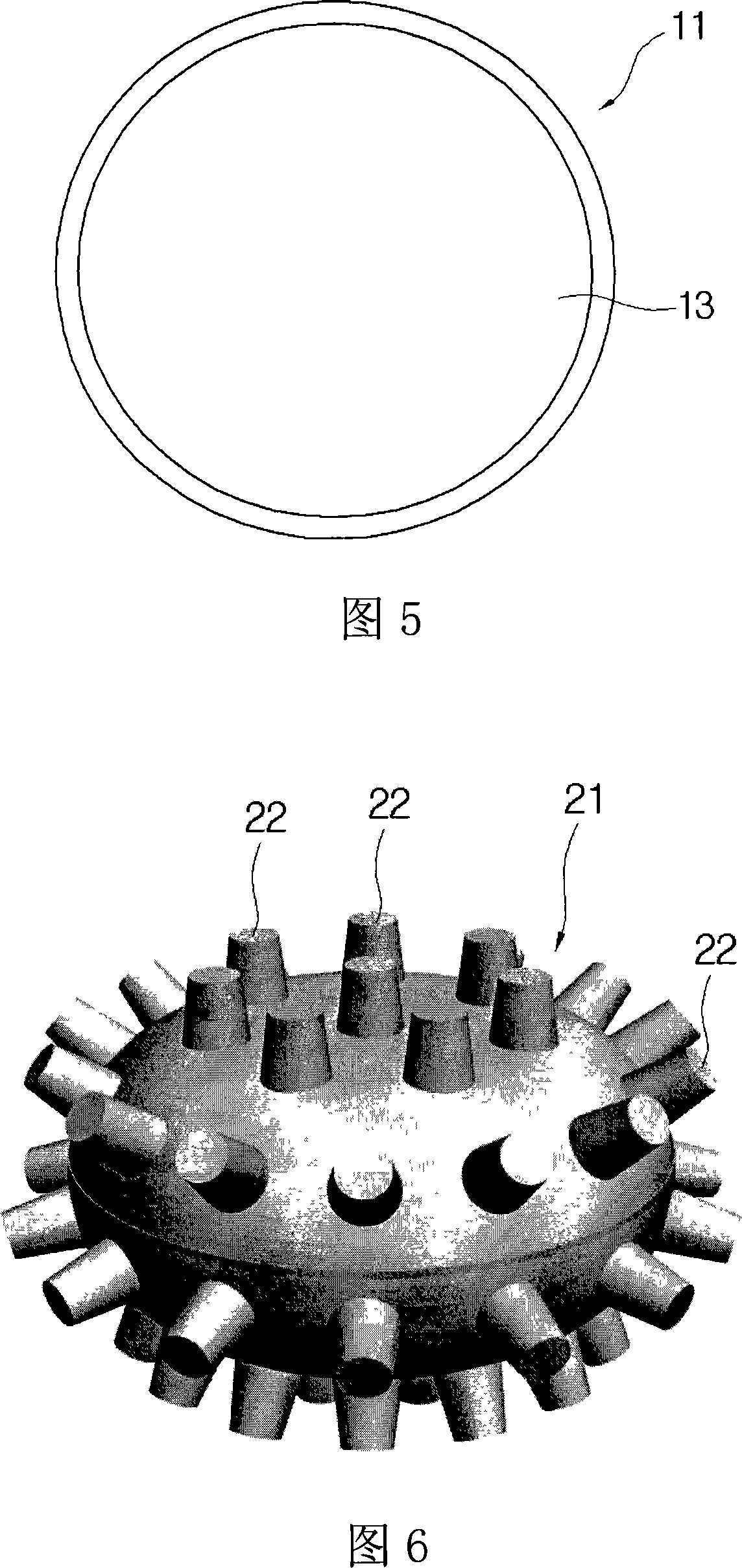

[0025] In addition, FIG. 6 is a display view of another embodiment of the cushion block of the present invention, FIG. 7 is a display view of the state of filling the cushion block of the present invention in a truss structure, and FIG. 8 is a display view of a floor made of the cushion block of the invention. .

[0026] The cushion block (1) of the present invention shown in Figures 1 to 3 is ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap