Constant spring hanger

A technology of constant force springs and hangers, which is applied in the direction of springs/shock absorbers, cup springs, pipe supports, etc., and can solve problems such as high manufacturing costs and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

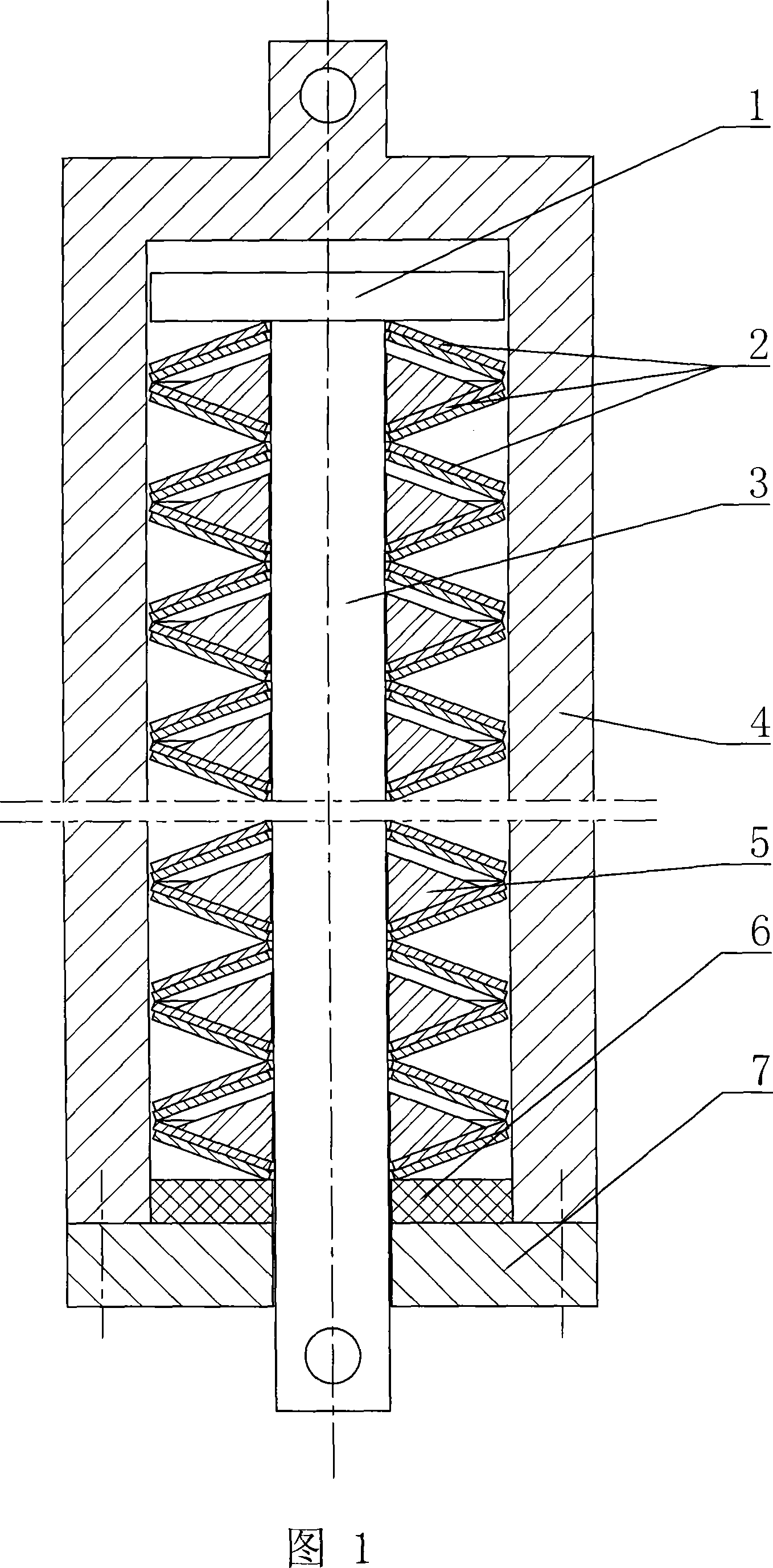

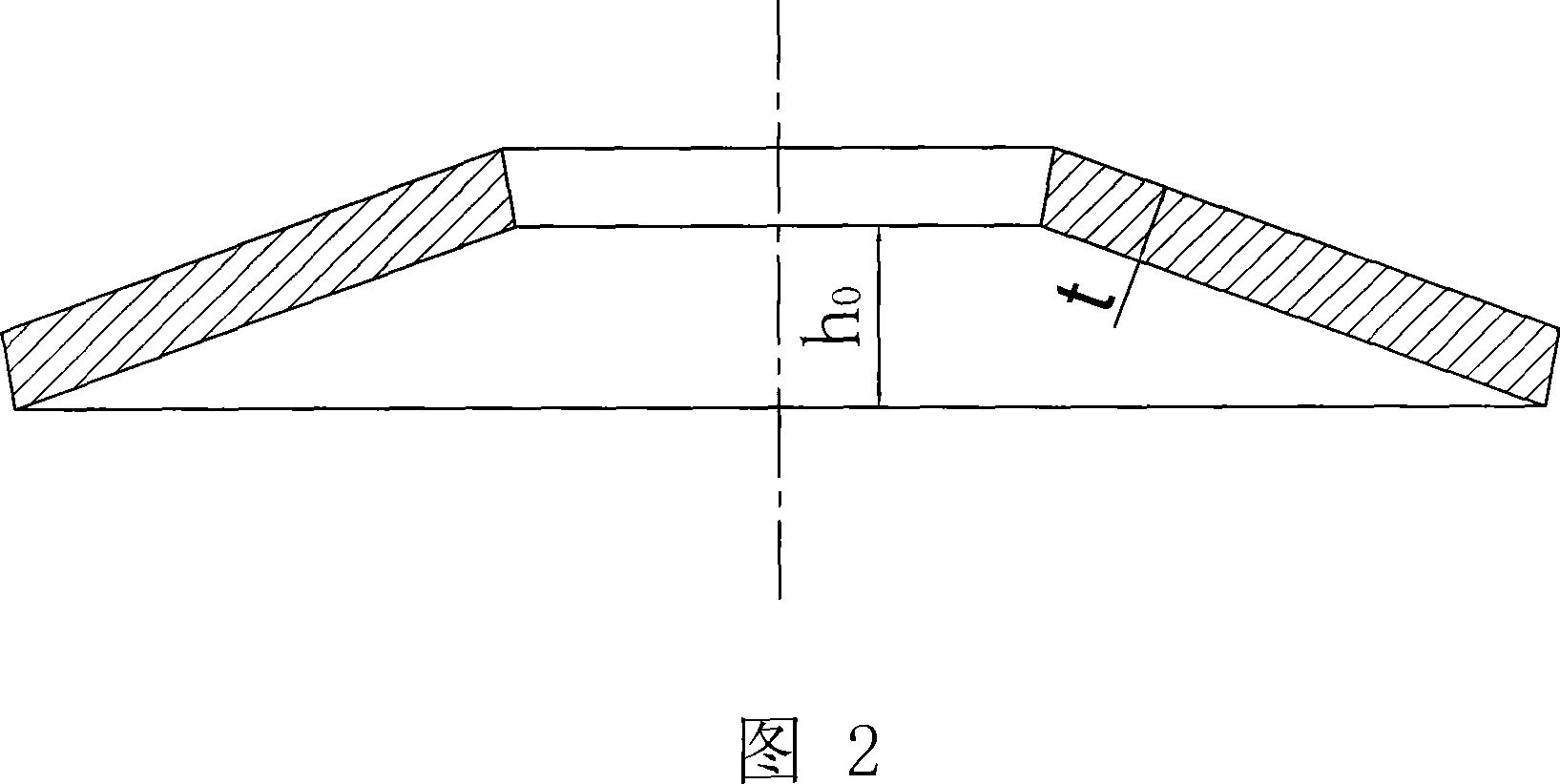

[0009] As shown in the figure, it is a constant force spring hanger, including a housing 4 and a load rod 3. The housing 4 is hollow, the load rod 3 is arranged in the housing 4, and the lower end of the load rod 3 extends from the bottom cover of the housing 4 Outside the housing 4, a pull plate 1 is fixed at the upper end of the load rod 3. A number of disc spring groups are arranged between the pull plate 1 and the bottom cover 7 of the housing 4, and each disc spring group has two pieces. The same disc springs 2 are superimposed (superimposed means that at least two disc springs are stacked together in the same direction); the two adjacent disc spring groups are arranged in opposite directions, and the inner cone of the disc spring 2 The ratio of the height h0 to the thickness t is 1.5-2.0, and the best value is 1.75. A limit block 5 is provided between the two disc spring groups arranged in order to prevent the disc spring 2 from flanging (the arrangement is Refers to the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com