Making method for key light guide plate

A manufacturing method and technology of a light guide plate, applied to optical components, electrical components, electrical switches, etc., can solve problems such as slow production efficiency, inability to gather and refract light, and defects in light guide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical content and detailed description of the present invention are described as follows in conjunction with the accompanying drawings.

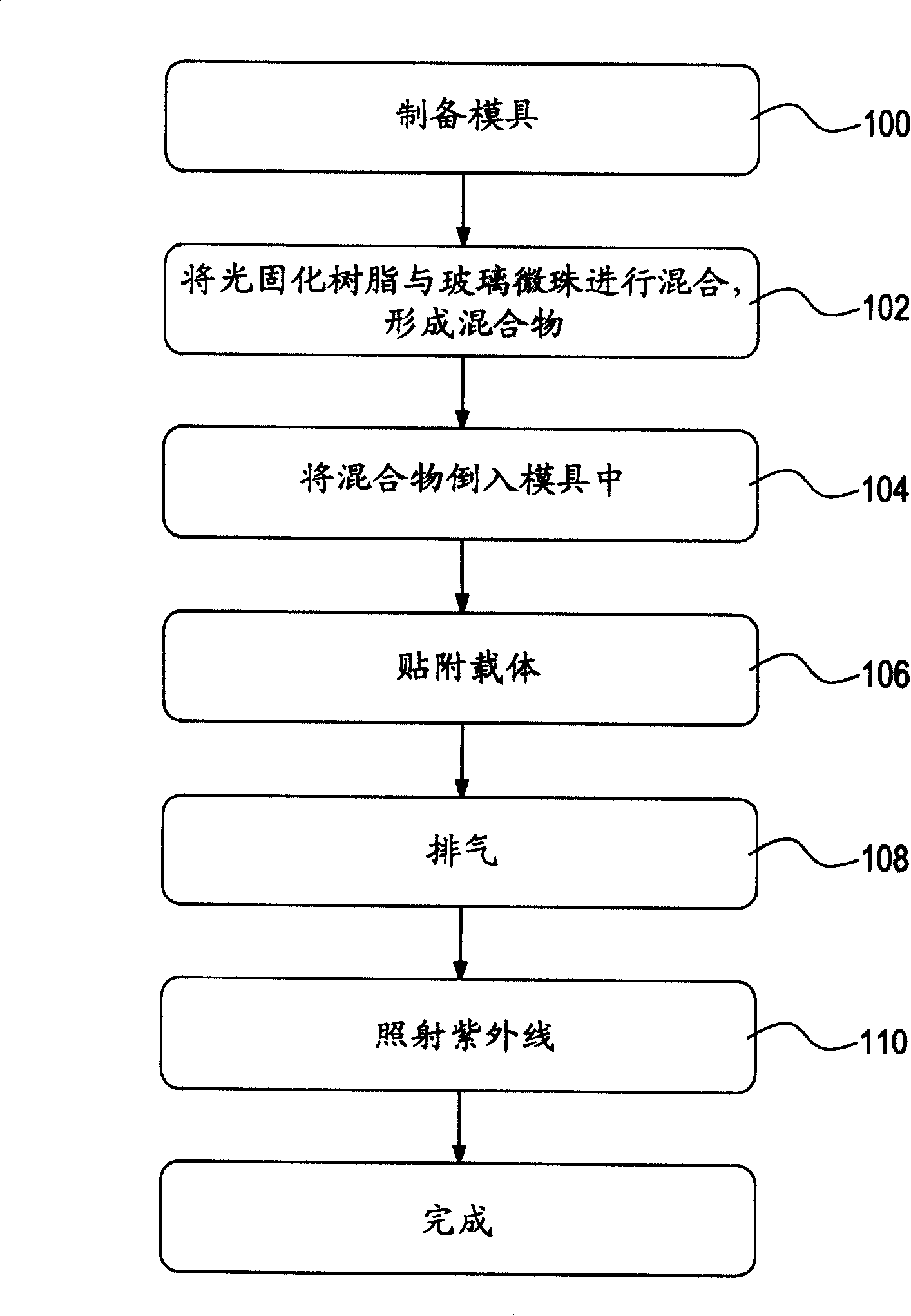

[0047] figure 1 It is a schematic diagram of the manufacturing process of the light guide plate of the present invention. As shown in the figure, this figure discloses a method for manufacturing a light guide plate used inside a keypad structure. First, a mold is prepared, such as step 100 .

[0048] Step 102, mixing the photocurable resin and the glass microspheres to form a mixture. In this figure, the photocurable resin is a UV curable resin.

[0049] Step 104, pour the mixture into the mold.

[0050] Step 106, attaching the carrier on the mixture. In this figure, the carrier is any one of transparent and colorless PC (polycarbonate) film or TPU (thermoplastic polyurethane) film.

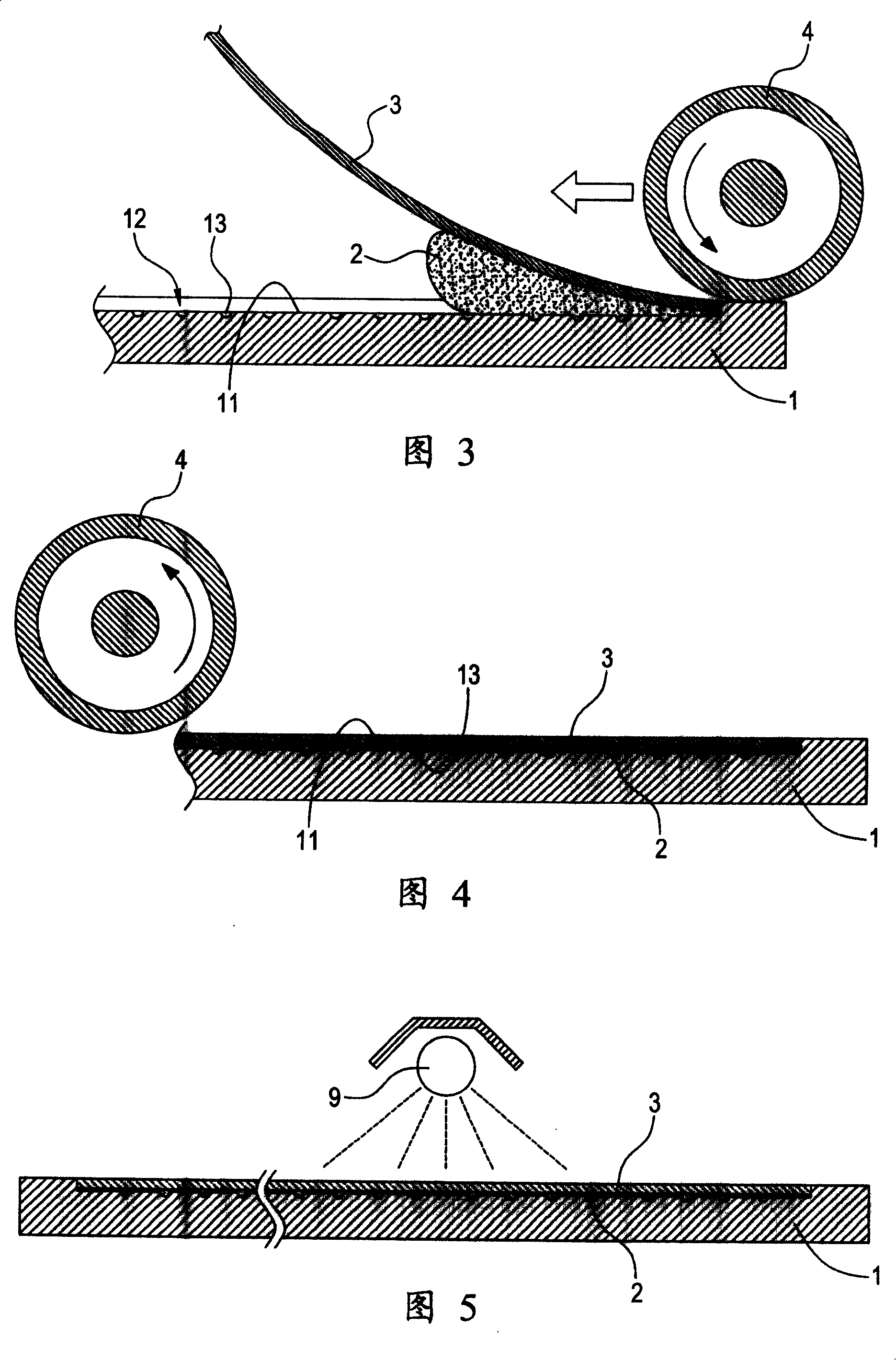

[0051] Step 108 , use a rolling tool to roll on the surface of the carrier, so that the mixture can be evenly filled in the mold, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com