Automatic ligation device

A ligator and automatic technology, applied in the field of medical devices, can solve the problems of prolonged operation time, expensive use, and high product cost, and achieve the effects of cost reduction, fewer ligatures, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

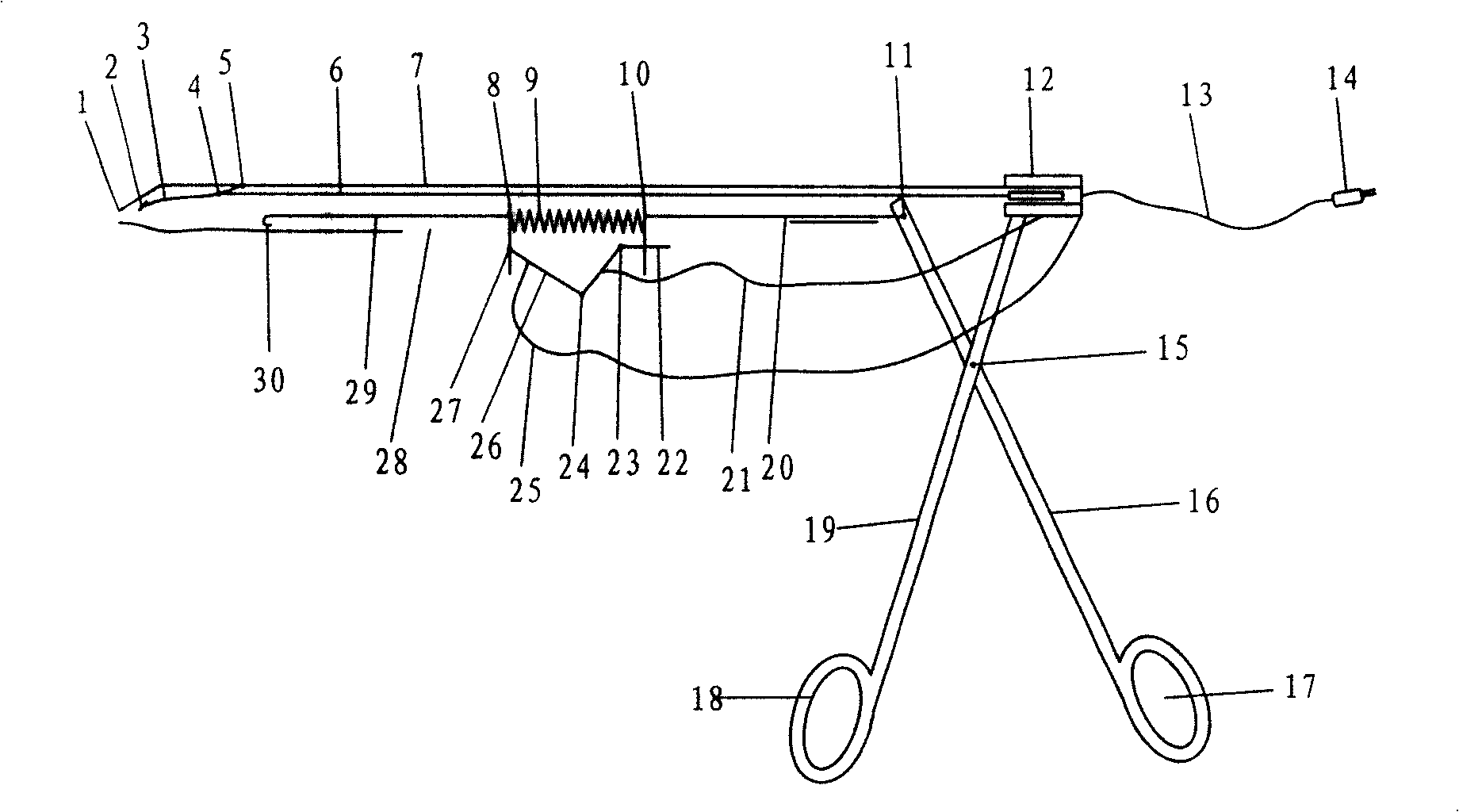

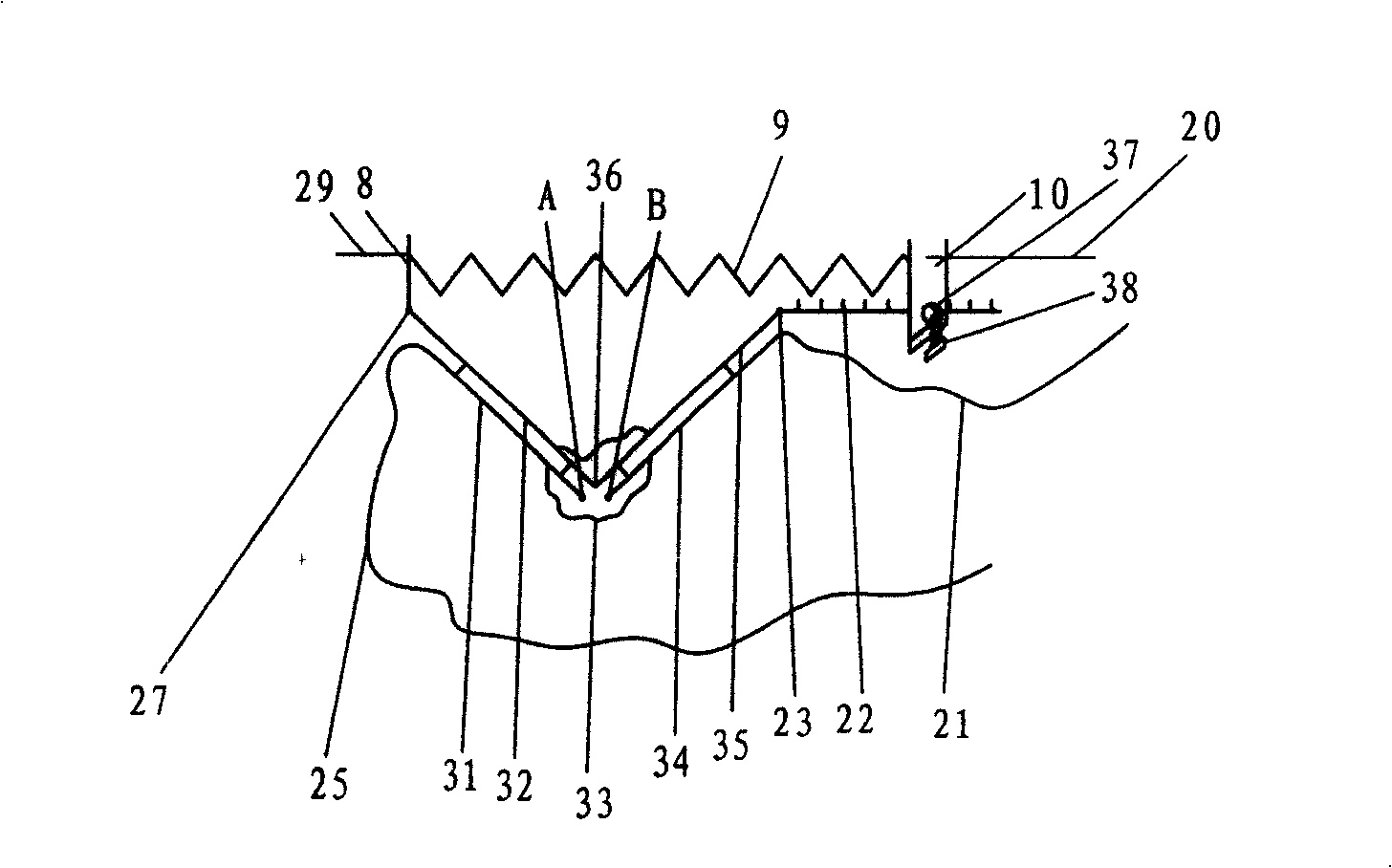

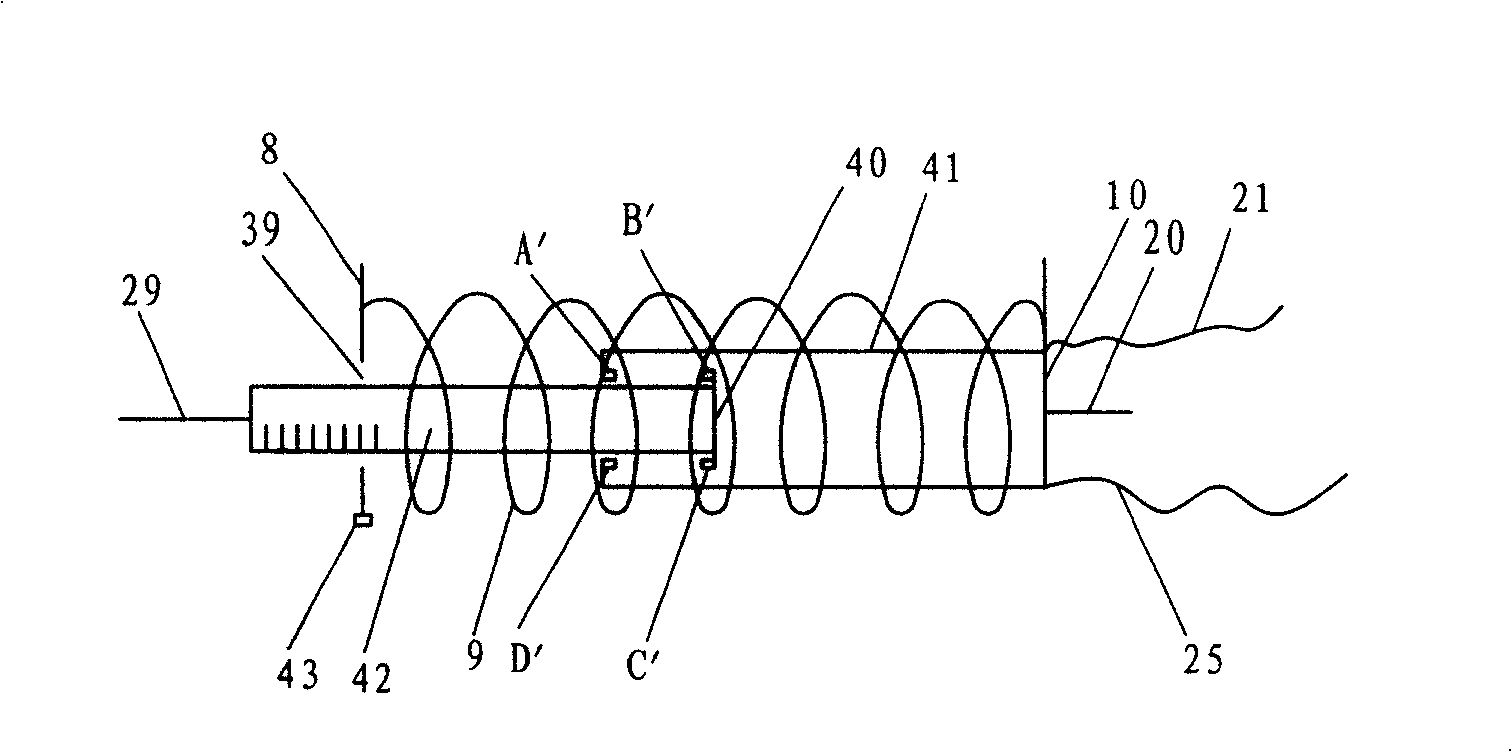

[0016] Such as figure 1 Shown, automatic ligator is made up of backguy tube 7, thread cutter 2, backguy bar 29, pull switch 26, pull bar 20, traction electromagnet 12, fixed handle 19, movable handle 16. The front end of backguy tube 7 dwindles to form blocking knot hole 1, and the rear end links to each other with the outer wall of traction electromagnet 12, both are fixed on fixed handle 19, and the armature of traction electromagnet 12 is opposite to the lumen of backguy tube 7. The thread cutter 2 is fixed to the point 5 on the inner side wall of the cable tube 7 through the elastic handle 3. Under the condition of no external force, the elastic handle 3 bounces the thread cutter 2 to reveal the inner side of the knot hole 1. The middle part of the elastic handle 3 is connected to the point 4 with the front end of the thin steel wire 6, and the rear end of the thin steel wire 6 is connected with the armature of the traction electromagnet 12. The traction electromagnet 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com