Multipurpose composite direct twisting type twisting machine

A twisting machine and direct-twisting technology, applied in the textile field, can solve problems such as staying in theoretical exploration, and achieve the effects of outstanding economic benefits, low energy consumption, and eliminating the need for rewinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

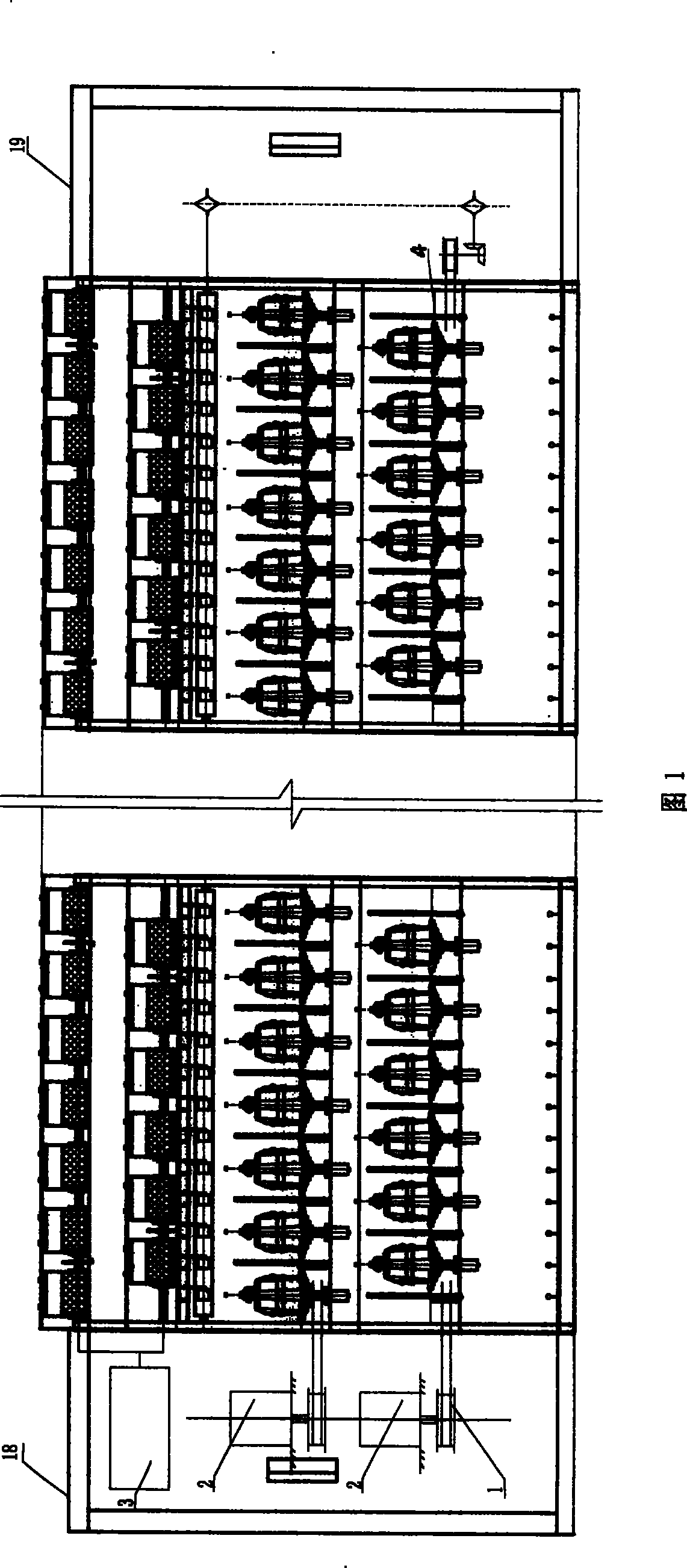

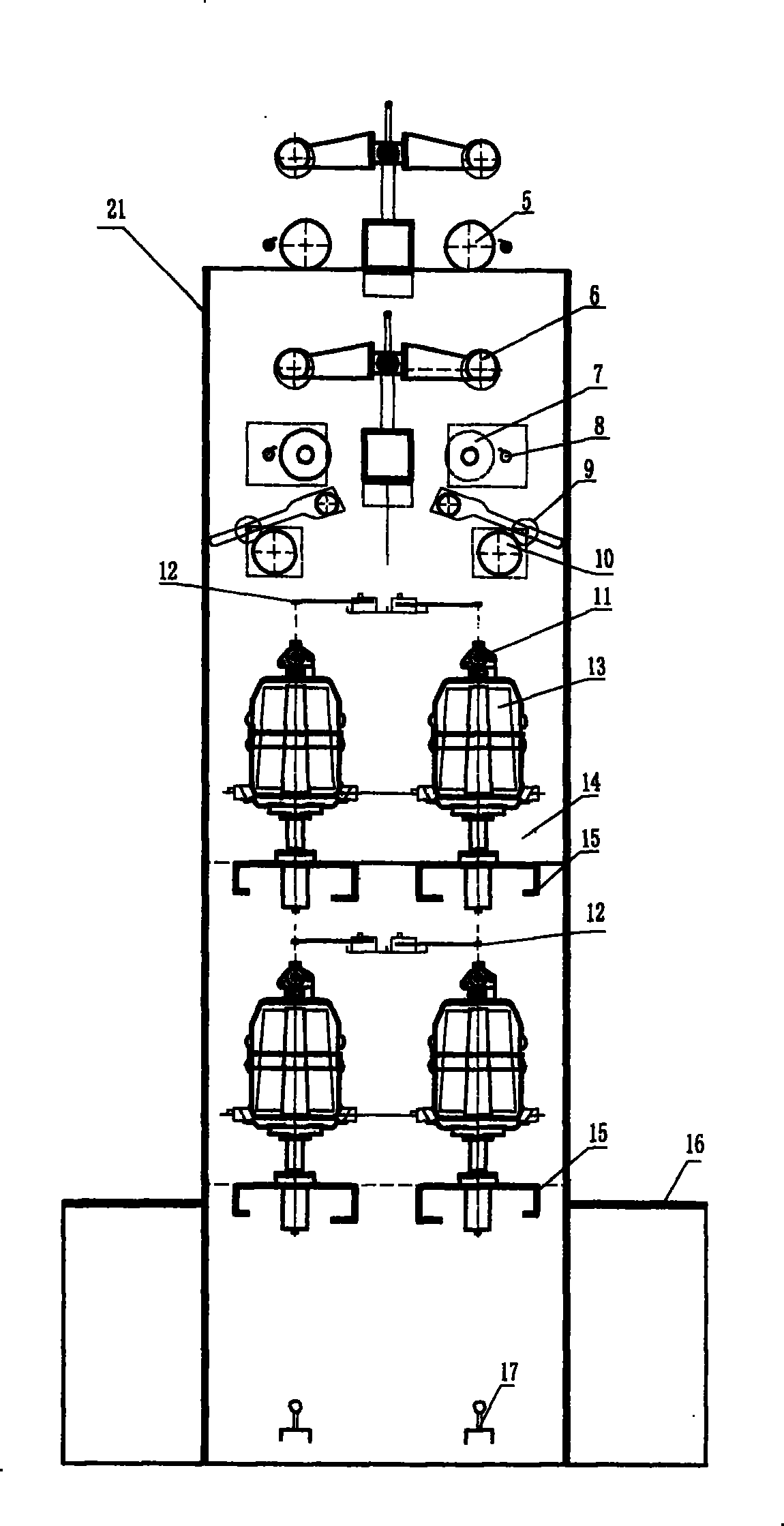

[0039] Such as figure 1 , 2 , Shown in 3, 4, what the present invention proposes is a kind of multi-purpose composite straight-twisting type thread twisting machine, is applicable to the twisted thread of embroidery thread, nylon, polyester, rayon, sewing thread etc.

[0040] The multi-purpose composite straight twist twister of the present invention comprises a frame, a spindle transmission device, a spindle assembly, a tension mechanism, a wire guide mechanism, a bobbin forming mechanism, and an electric control device.

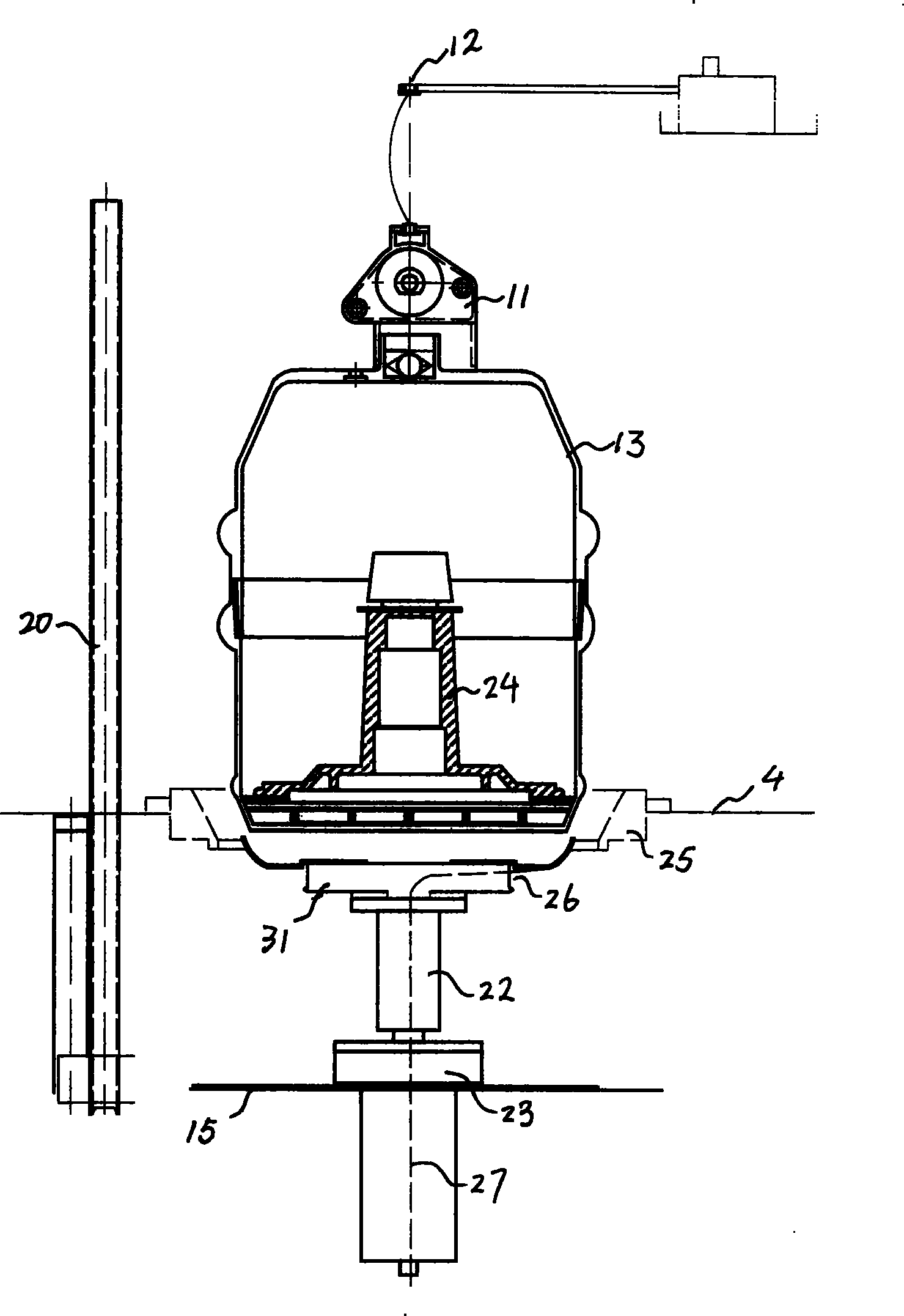

[0041]The spindle assembly includes a spindle driven by a spindle transmission device, a twisting disc 31, and a yarn pot 13. The spindle is composed of a spindle rod 22 and a spindle seat 23; out, and the tension is controlled by the first tensioner 11 installed on the upper end of the yarn pot 13; the yarn bobbin holder 24 is sleeved on the upper end of the spindle bar 22 through the bearing, and the twisting disc 31 is located at the lower end of the ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com