Direct twisting type twisting technique

A direct-twisting and technological technology, applied in the field of direct-combined twisting process, can solve problems such as staying in theoretical exploration, and achieve the effects of outstanding economic benefits, reduced energy consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

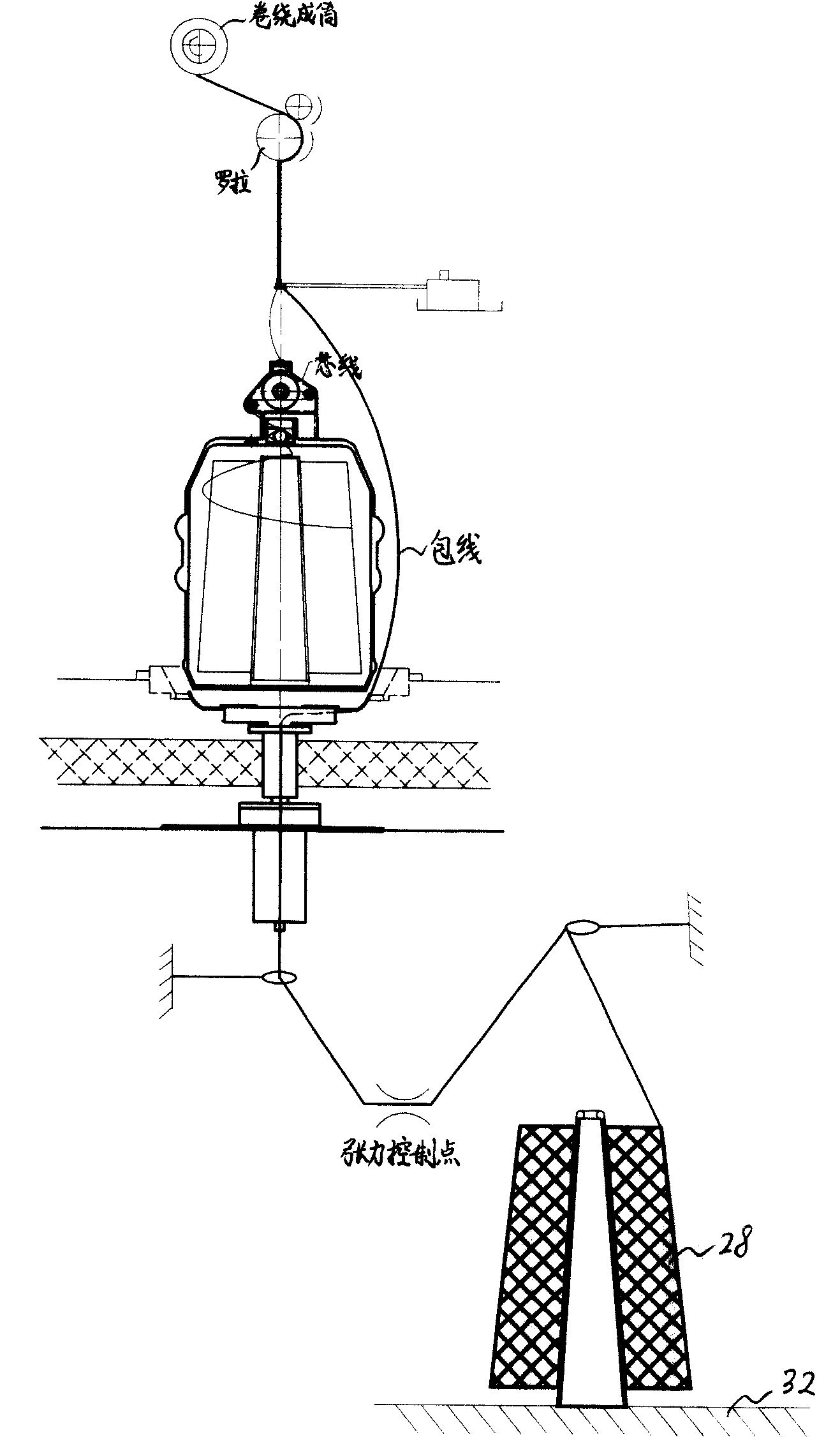

[0049] Process of the present invention is:

[0050] A. The first yarn bobbin is loaded into the yarn pot, and the first yarn is pulled out from above the yarn pot, and the tension is controlled by the tensioner;

[0051] B. The second bobbin is placed on the creel at the lower end of the first bobbin, and the second yarn enters the hollow spindle through the thread guide mechanism, and the tension is controlled by a tensioner before passing through the twisting disc on the hollow spindle. With the rotation of the hollow spindle, it is thrown out of the hollow spindle, and the upper end is wrapped with the first yarn to rotate around the yarn pot in the form of a balloon, and the tension of the first yarn and the second yarn in the balloon state increases or decreases correspondingly with the change of the spindle speed ;

[0052] C. The first and second yarns are combined into one strand at the top of the balloon. When the two yarns are plyed, the tension of the two yarns is...

Embodiment 2

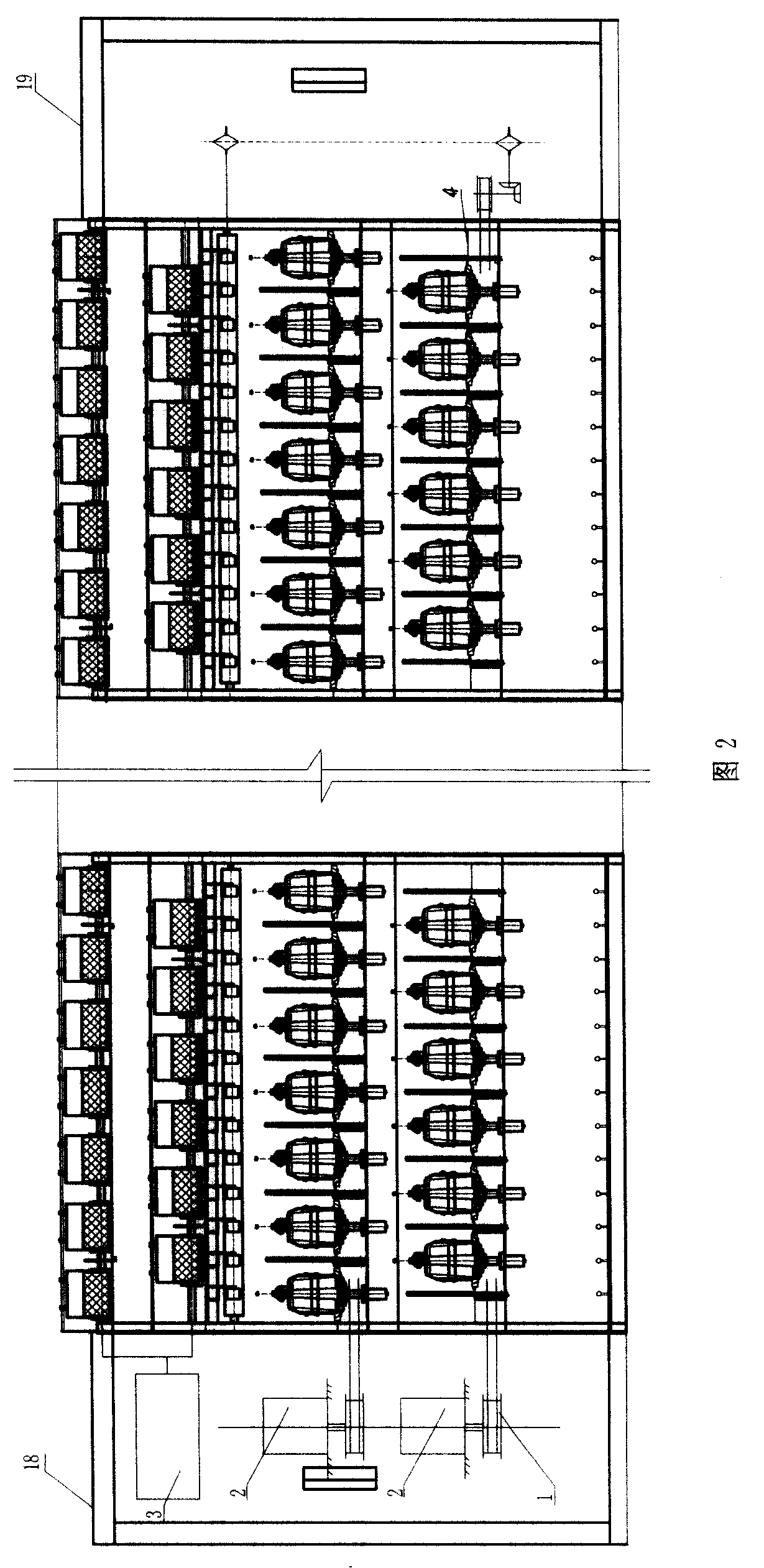

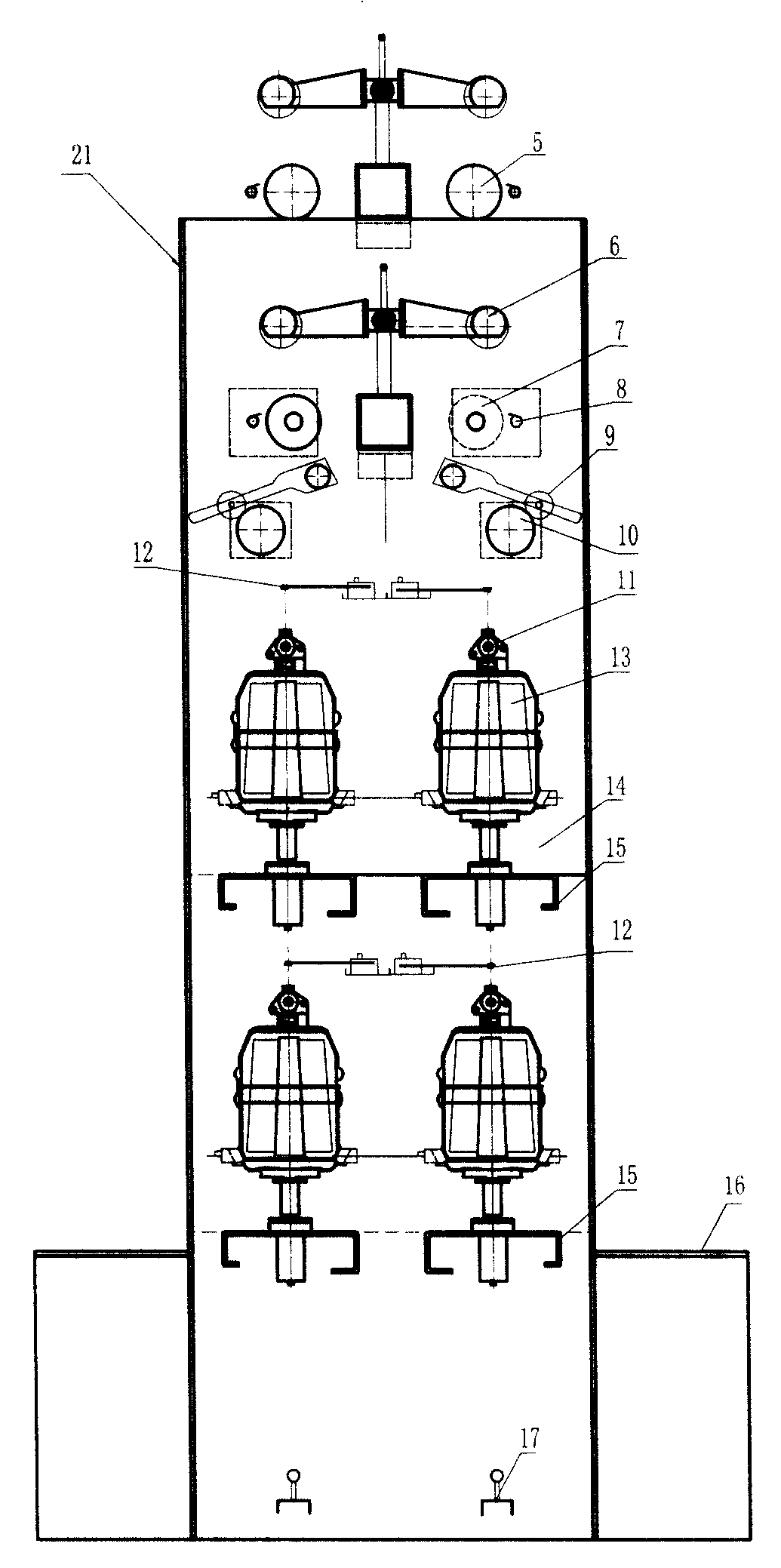

[0054] As shown in Figure 2, image 3 As shown, in the present invention, each spindle position on the twisting machine is provided with at least two layers of spindle assemblies up and down, a first yarn bobbin and at least two rows of second yarn bobbins in front and back, and multi-layer operations are carried out on one spindle position.

Embodiment 3

[0056] Such as figure 1 ,figure 2, image 3 Shown, the yarn running route of the present invention is:

[0057] The first yarn: bobbin, first tensioner, ply yarn guide;

[0058] The second yarn: yarn bobbin, yarn guide mechanism, second tensioner, yarn guide, spindle center hole, spindle core-embedded steering, twisting disc, ply yarn guide;

[0059] After plying: Roller traction, bobbin forming mechanism, including traversing screw rod, friction drum, winding tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com