Multi-head ball screw device

A ball screw, multi-head technology, applied in the direction of the transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of displacement speed limitation, small helix angle, and screw transmission device is incompetent, so as to improve the displacement speed and increase the speed. Effect of large helix angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

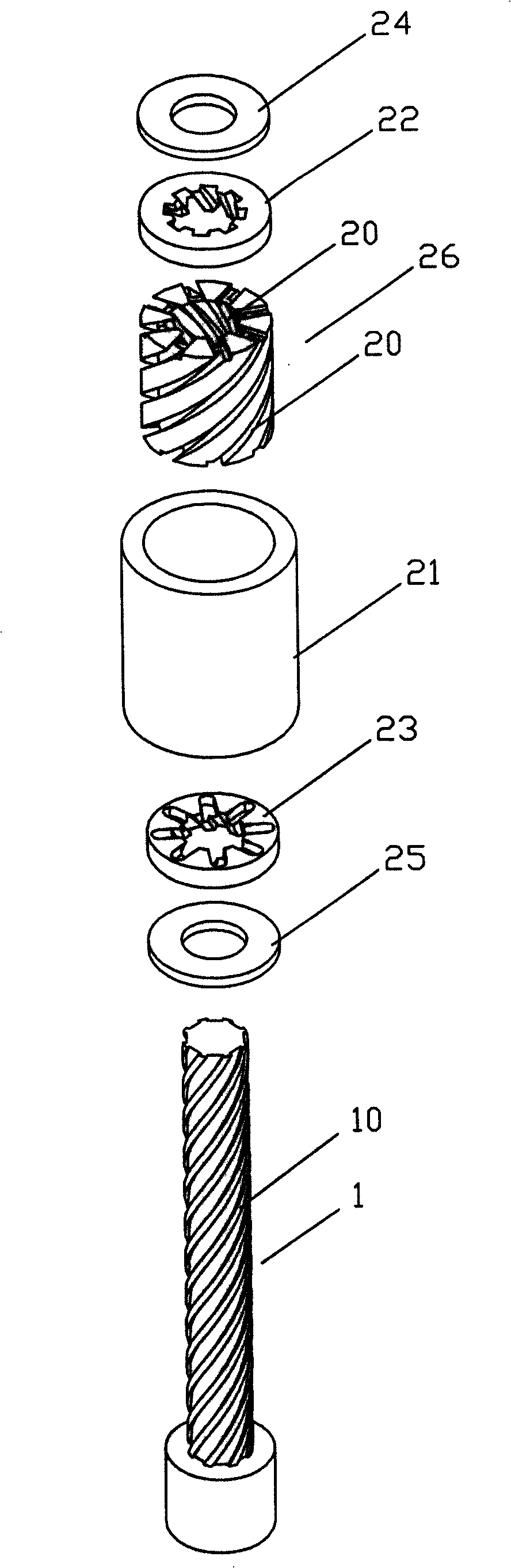

[0011] A multi-head ball screw device, including a screw shaft 1 with a raceway groove 10, a nut 2 with a raceway groove 20, and balls carried between the screw shaft 1 and the nut 2 (not shown in the figure) , Wherein, nut 2 is made up of outer cover 21, upper guide plate 22, lower guide plate 23, upper end cover 24, lower end cover 25 and nut main body 26.

[0012] The interacting raceway grooves (10, 20) described in this embodiment are composed of 8 helical grooves. In this way, through the combination of multi-head spiral grooves, the transmission load capacity and stability are improved. Therefore, the present invention can adopt a larger helix angle, thereby increasing the transmission speed and meeting the transmission occasions that require low speed and large displacement.

[0013] The specific embodiments described above are only preferred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com