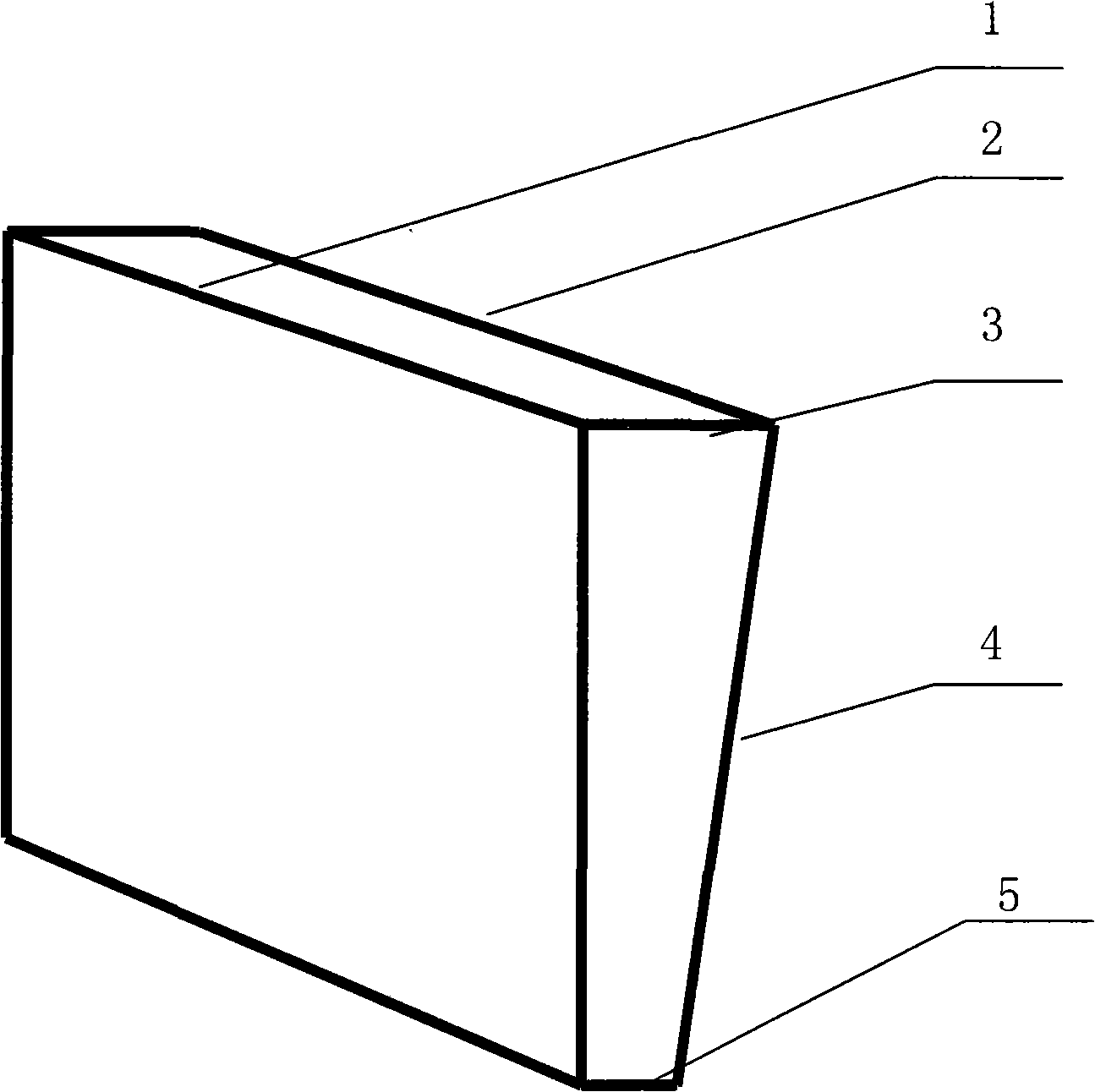

Cross section special-shaped tile

A technology of special-shaped cross-section and ceramic tiles, which is applied in the field of building decoration materials, can solve the problems of reducing the bonding area and reducing the bonding strength, and achieves the effect of wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

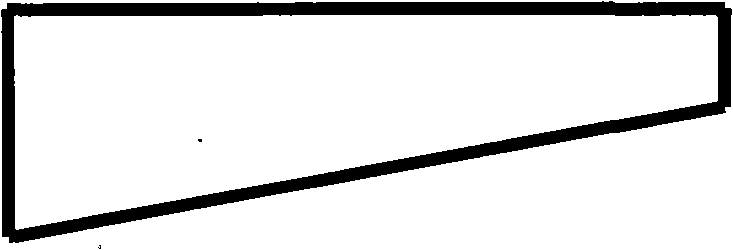

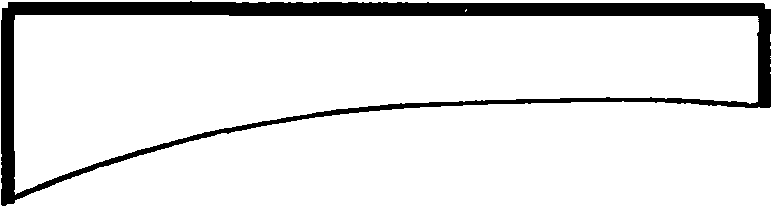

Embodiment 1

[0023] The beige floor tiles are 40 cm long and 40 cm wide, with a thin side of 1 cm thick and a thick side of 2 cm. The back is sloped, and is used for indoor flooring in the kitchen. Spread the cement on the ground, hold the thin side with one hand, put the thick side on the cement first and keep the tiles level, and hold the wooden stick with the other hand to lightly beat from the thick side, the wooden stick gradually moves to the thin side and lightly beats, Until the beveled edge on the back of the tile completely squeezes out the cement and air, then continue laying the next tile according to the above method. It has been used for 5 years after construction and has not fallen off or broken.

Embodiment 2

[0025] White glazed wall tiles, 30cm long, 20cm wide, 0.4cm thick on the thin side, 0.8cm thick on the thick side, concave on the back, used for bathroom wall laying. To apply cement to the wall, the operator holds the thin side of the tile with one hand, puts the thick side on the wall cement first, and makes the tile vertical to the ground, and then uses a wooden paddle to gradually move from the thick side to the thin side of the tile and tap it lightly , until the cement and air are completely squeezed out on the back of the tile, and then continue to lay the next tile according to the above method.

Embodiment 3

[0027] Corrosion-resistant tiles are made of quartz, feldspar, and clay and fired at high temperature. They are used for laying the inner wall of acid pools for derusting steel in factories. Corrosion-resistant tiles are 30 cm long and 30 cm wide, with a thin side of 0.5 cm thick, a thick side of 1 cm, and a convex back. Spread the cement on the bottom of the pool, hold the thin side of the tile with one hand, put the thick side on the cement, and use the other hand to lightly beat from the thick side with a wooden paddle, and gradually move to the thin side. Until the cement and air are completely squeezed out on the back of the tile, then continue laying the next tile according to the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com