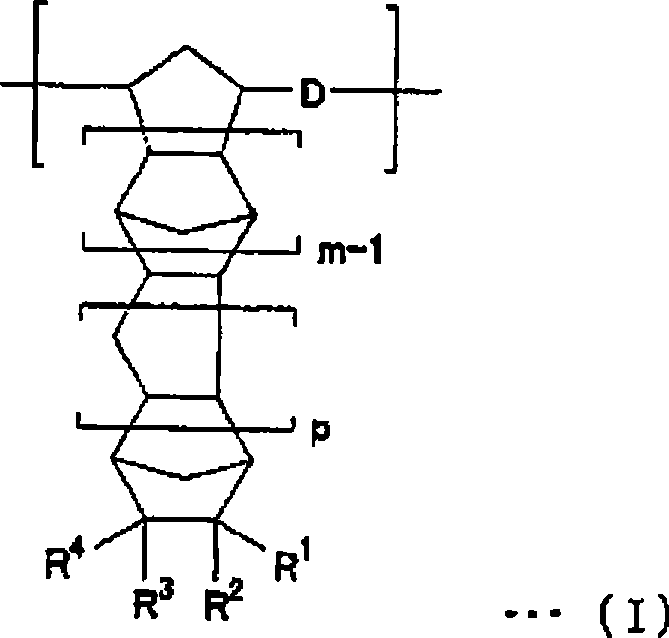

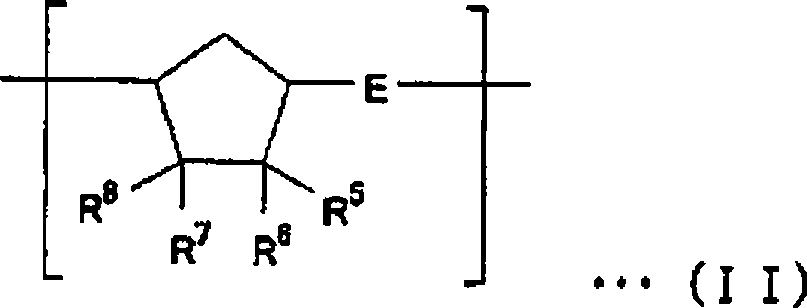

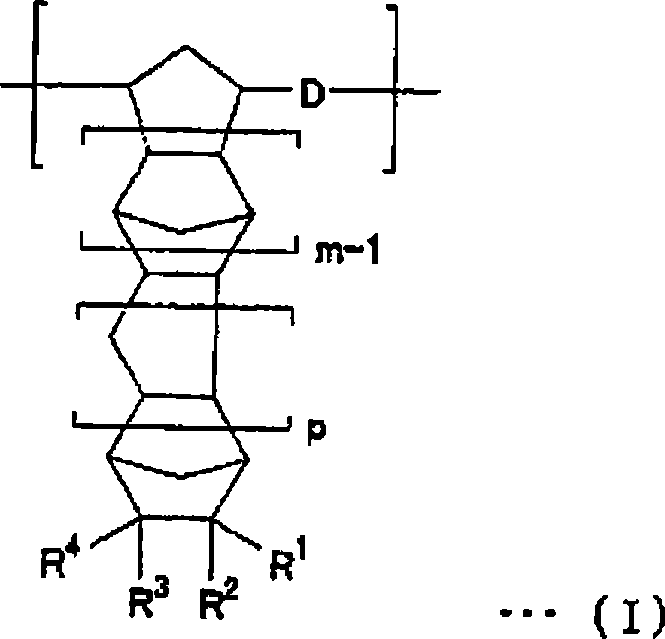

Optical film, polarizing plate, and liquid crystal display device

An optical film, optical anisotropy technology, applied in optics, optical elements, polarizing elements, etc., can solve the problems of uncomfortable optical anisotropy layer use, poor manufacturing efficiency, difficult to control the phase freely, etc., and achieve good viewing angle compensation effect. , to prevent light leakage, the effect of high contrast ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0321] Hereinafter, although an Example is given and this invention is demonstrated more concretely, this invention is not limited to the following Example unless the summary is exceeded. In addition, unless otherwise specified below, "part" and "%" mean "weight part" and "weight%".

[0322] The measurement methods of various measurement values in the present invention are shown below.

[0323]

[0324] Using a differential scanning calorimeter (DSC) manufactured by Seiko Instruments, the measurement was performed in a nitrogen atmosphere at a temperature increase rate of 20° C. / min.

[0325]

[0326] According to ASTM D570, the sample was immersed in 23 degreeC water for 1 week, and the weight change before and after immersion was measured, and it calculated|required.

[0327]

[0328] The measurement was performed using a haze meter (HGM-2DP type) manufactured by SUGA TEST INSTRUMENTS.

[0329]

[0330] The measurement was performed using "KOBRA-21ADH" manufactur...

Synthetic example 1

[0340] 8-Methyl-8-methoxycarbonyltetracyclo[4.4.0.1 2,5 .1 7,10 250 parts of ]-3-dodecene (specific monomer), 18 parts of 1-hexene (molecular weight modifier) and 750 parts of toluene (solvent for ring-opening polymerization reaction) were loaded into a reaction vessel replaced by nitrogen, and the The solution was heated to 60°C. Then, in the solution in the reaction vessel, add 0.62 parts of toluene solution of triethylaluminum (1.5 mol / l) as a polymerization catalyst, tungsten hexachloride modified with tert-butanol and methyl alcohol (tert-butanol: methanol: tungsten = 3.7 parts of toluene solution (0.35 mol: 0.3 mol: 1 mol) (concentration: 0.05 mol / l), this solution was heated and stirred at 80° C. for 3 hours to perform ring-opening polymerization reaction to obtain a ring-opened polymer solution. The polymerization conversion rate of this polymerization reaction was 97%. The logarithmic viscosity of the obtained ring-opened polymer measured in chloroform at 30°C wa...

Synthetic example 2

[0351] Using 8-methyl-8-methoxycarbonyltetracyclo[4.4.0.1 2,5 .1 7,10 215 parts of ]-3-dodecene, 35 parts of bicyclo[2.2.1]hept-2-ene, and 18 parts of 1-hexene (molecular weight regulator), in the same manner as in Synthesis Example 1 except that A hydrogenated polymer (hereinafter referred to as "resin A2") was obtained.

[0352] The resulting resin A2:

[0353] The hydrogenation rate is 99.9%,

[0354] The glass transition temperature (Tg) measured by the DSC method is 125°C,

[0355] The polystyrene-equivalent Mn measured by the GPC method (column and solvent were the same as in Synthesis Example 1) was 46,000, Mw was 190,000, and the molecular weight distribution (Mw / Mn) was 4.15,

[0356] The saturated water absorption rate at 23°C is 0.18%,

[0357] SP value is 19(MPa 1 / 2 ),

[0358] The logarithmic viscosity in chloroform at 30°C is 0.69dl / g,

[0359] The gel content is 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap