Dry optical - chemical carbon - dioxide sensor

An optical sensor, carbon dioxide technology, applied in scientific instruments, material analysis by optical means, analysis by chemical reaction of materials, etc., can solve problems such as difficulty in implementing sensor compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1: Sensors Comprising Use of Solubilized Metal Cations

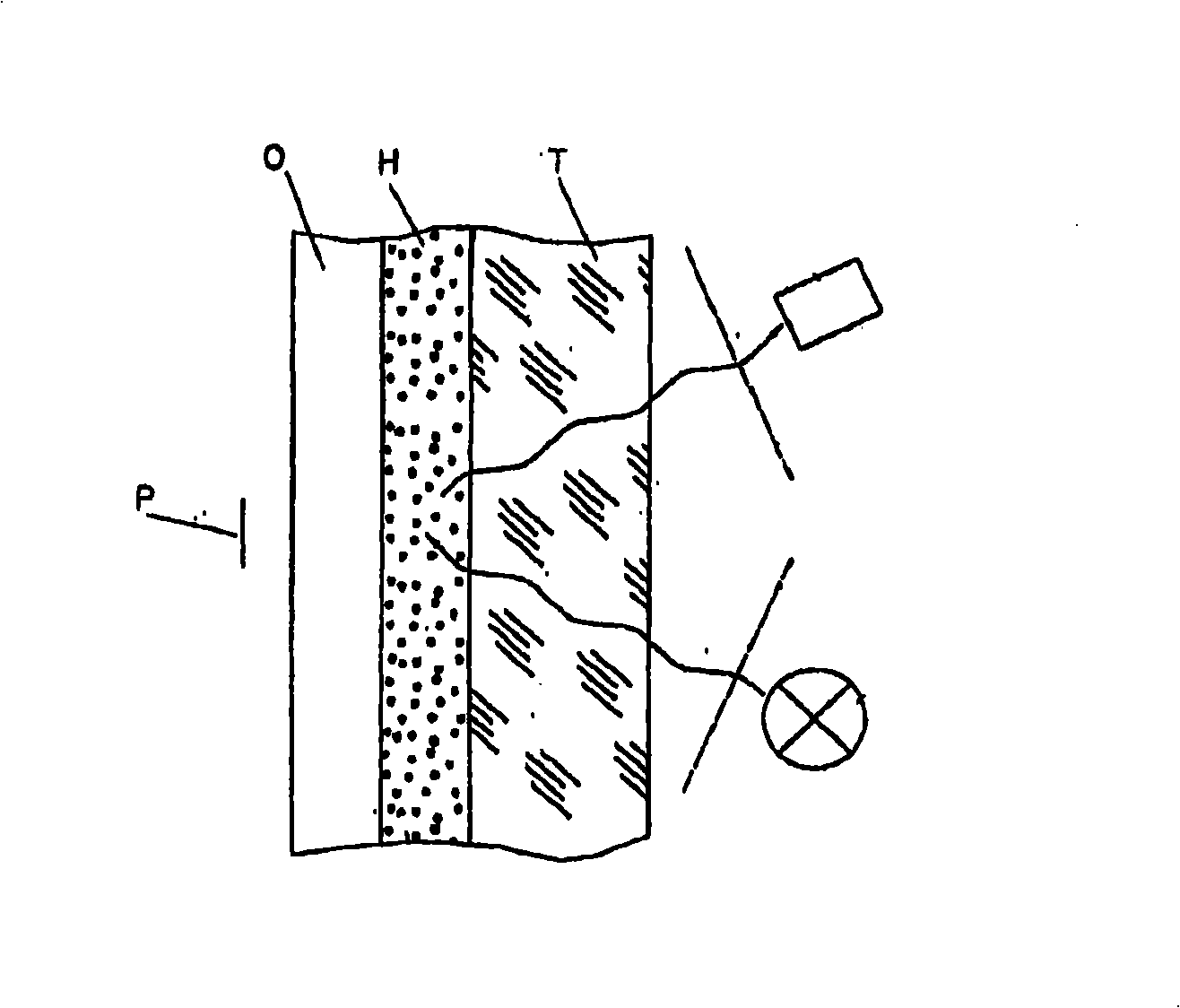

[0094] General formulation: ethylcellulose / HPTS tris(K-crown 6) salt / (Z-crown 6) hydroxide / white Teflon overlay (TiO in TeflonAF 2 )

[0095] Solution I: 10mg HPTS

[0096] 34.7mg 18-crown-6

[0097] 955.3mg Methanol

[0098] Solution II: 15.0 mg KOH

[0099] 157.9mg 18-crown-6 (Aldrich 34682)

[0100] 1326.7mg Methanol

[0101] Fabrication of Optical Sensors

[0102] To 1 g of 10% w / w ethylcellulose in toluene / ethanol (4 / 1 v / v) was added 26 mg of solution I. To this mixture was added 56.2 mg of solution II and this casting solution was mixed thoroughly, and the corresponding uniform coating solution was coated on a 125 μm polyester sheet (Mylar foil, Goodfellow ES301425) using a knife coater (Zehntner ZAA2300) , with a wet film thickness of 150 μm. The dried sensor film is translucent. In addition, the sensor membrane was coated with a Teflon layer with a wet film thickness of 150 μm to enhance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com