Carpet structure with improved plastomeric foam backing

A backing, foam technology, applied in the field of foam backing, carpet and carpet tile products, manufacture of carpet and carpet tile, foam backing of carpet and carpet tile products, can solve a lot of time and energy , poor compatibility of foam pads, mechanical properties, tensile strength and impact strength, and aesthetic properties are adversely affected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

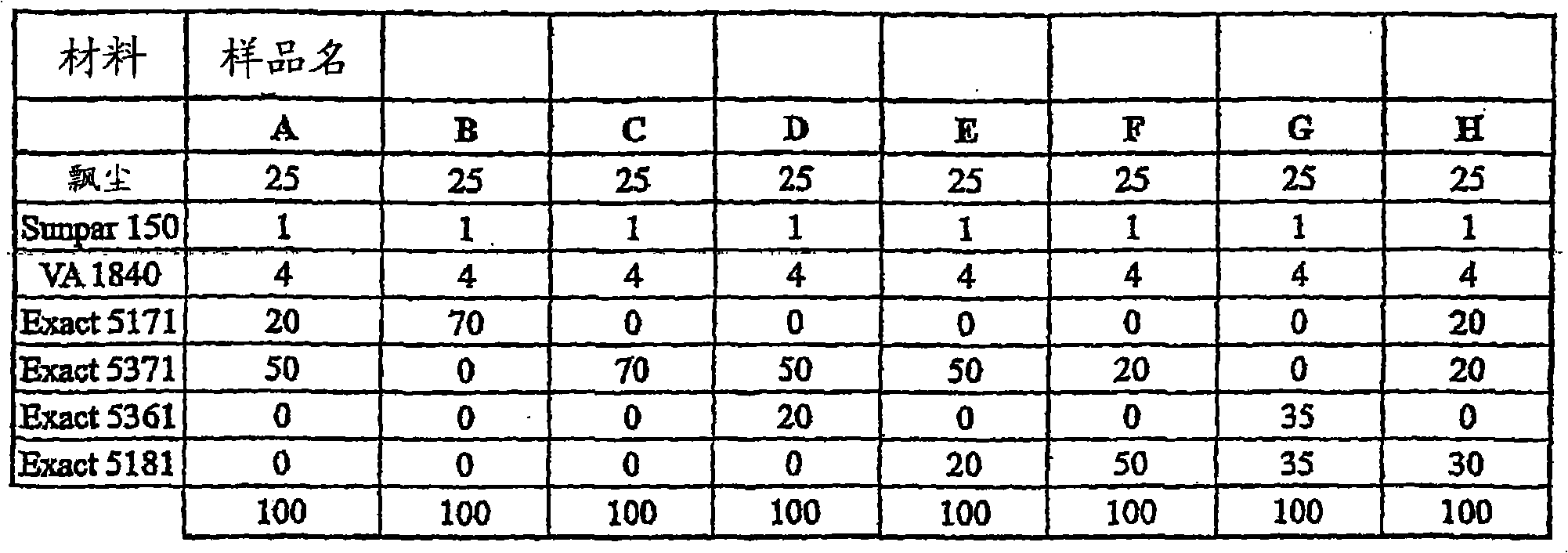

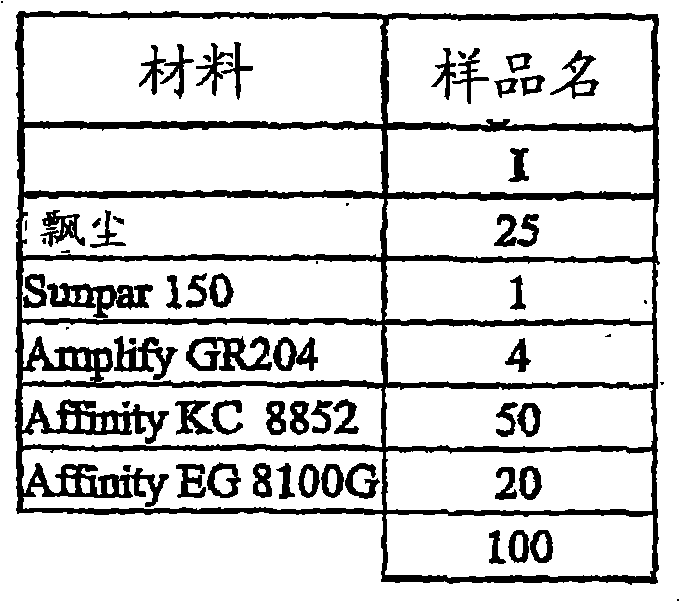

[0098] All samples contained 1% oil (Sunpar 150 paraffin oil, Sun Chemicals, Philadelphia, PA).

[0099] Unless otherwise stated, all samples contained post-added blowing agent mixed. (Note that the % of post-added blowing agent is relative to the mixture without blowing agent). The blowing agent is supplied as a 50% LDPE masterbatch formulation.

[0100] The compression resistance value is the average of 3 values.

[0101] Compression set and density are taken from a single measurement.

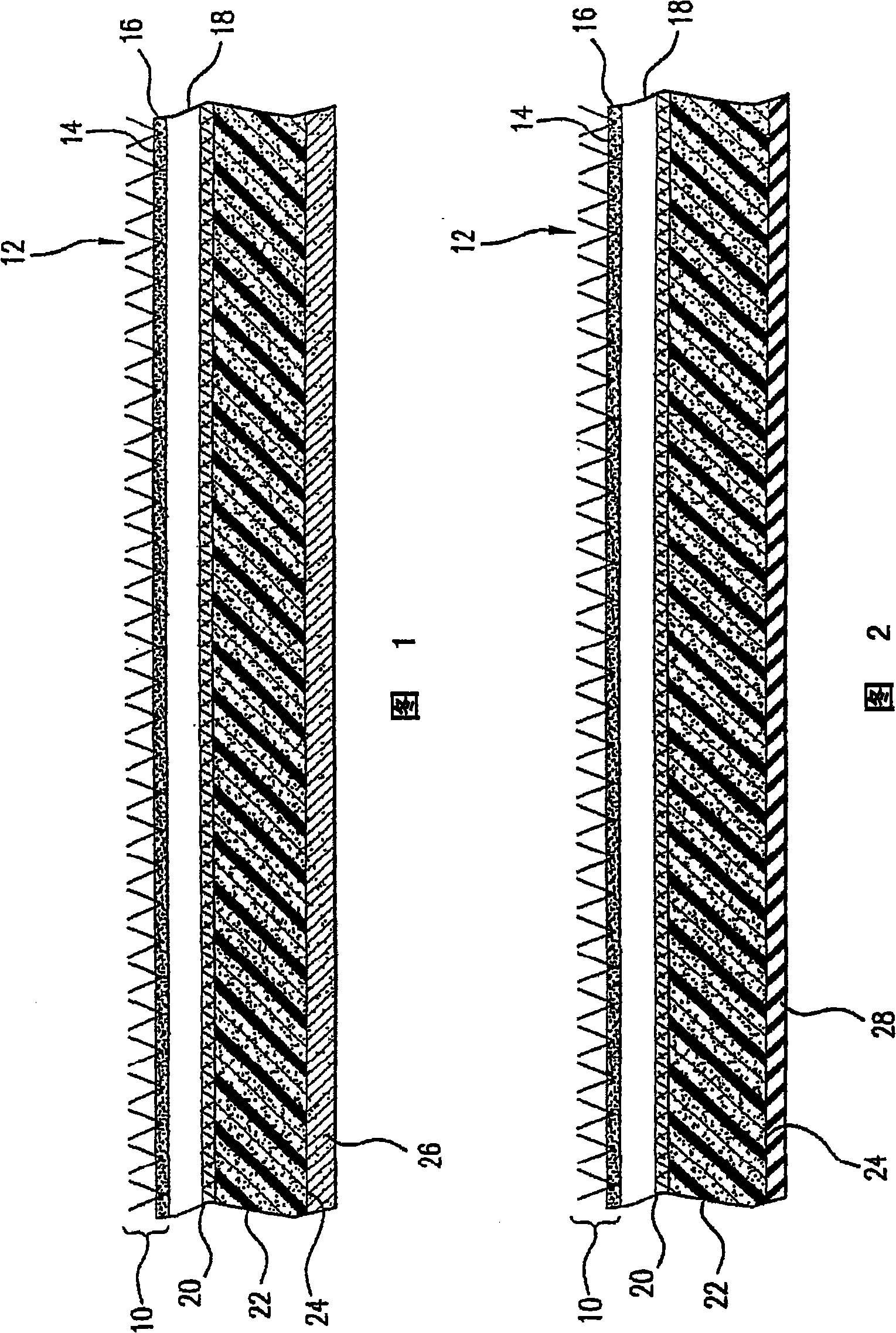

[0102] The samples consisted of fiberglass material foam as shown. The fiberglass material was applied according to the in situ method described in this application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com