Airtight dual-power roller blind sealing cap

A dual-power, closed-type technology, applied to motor vehicles, load coverage, and vehicles used for freight, can solve problems such as inconvenient use and maintenance, easy failure, poor reliability, etc., to ensure service life and work The effect of stability and light installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

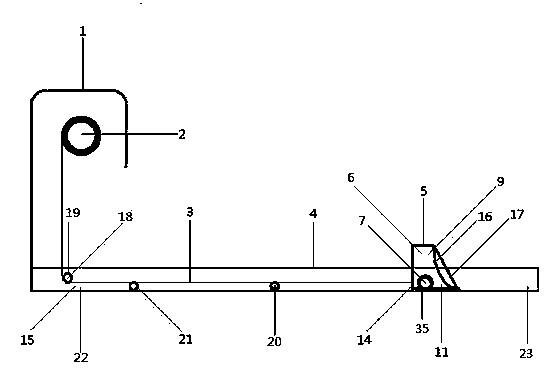

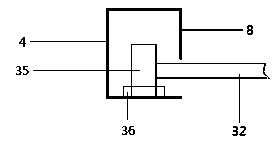

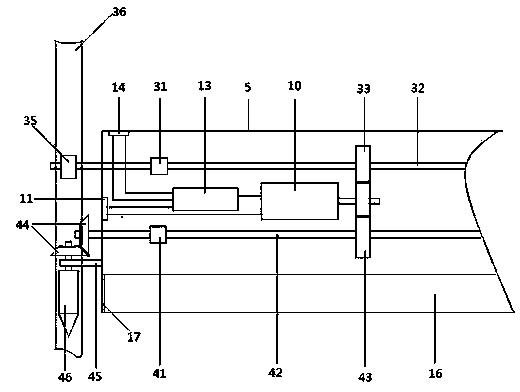

[0022] Referring to the accompanying drawings, a closed dual-power roller blind cover, the main structure includes a curtain barrel 1, a roller shutter mechanism 2, a curtain body 3, left and right U-shaped guide rails 4, a horizontal push frame 5, a power mechanism 6 and a motion mechanism 7. Wherein the curtain barrel 1 is installed on the front side of the car body, and the curtain barrel 1 is provided with a rolling shutter mechanism 2, which includes a motor, which is connected to a power supply and a control switch, and elastic rewinding devices such as coil springs can also be used to replace the motor. The roller blind mechanism 2 realizes the roller blind function through motor drive or coil spring rewinding. The left and right U-shaped guide rails 4 are fixed on the upper ends of both sides of the car body, and guide rail baffles 8 are set at the opening to prevent materials from entering the guide rails and affecting the cover; front and rear position sensors 22, 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com