Low-voltage plastic shell breaker element box device

A molded case circuit breaker and component box technology, which is applied to electrical components, emergency protection devices, circuits, etc., can solve the problems of low breaking capacity of circuit breakers, bulky circuit breakers, and increased arc voltage, so as to prevent abnormal The effect of opening and closing, reducing inventory, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

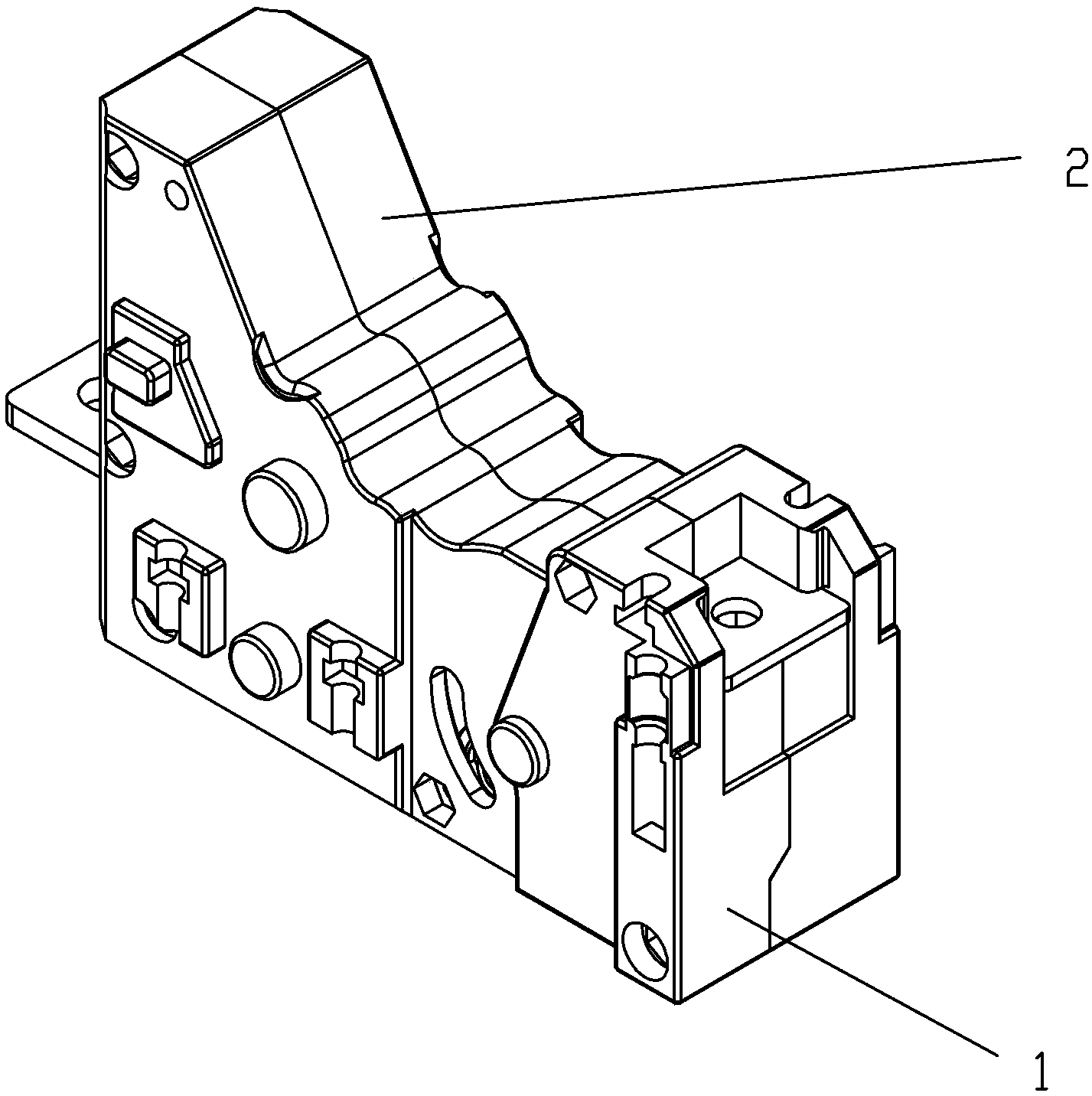

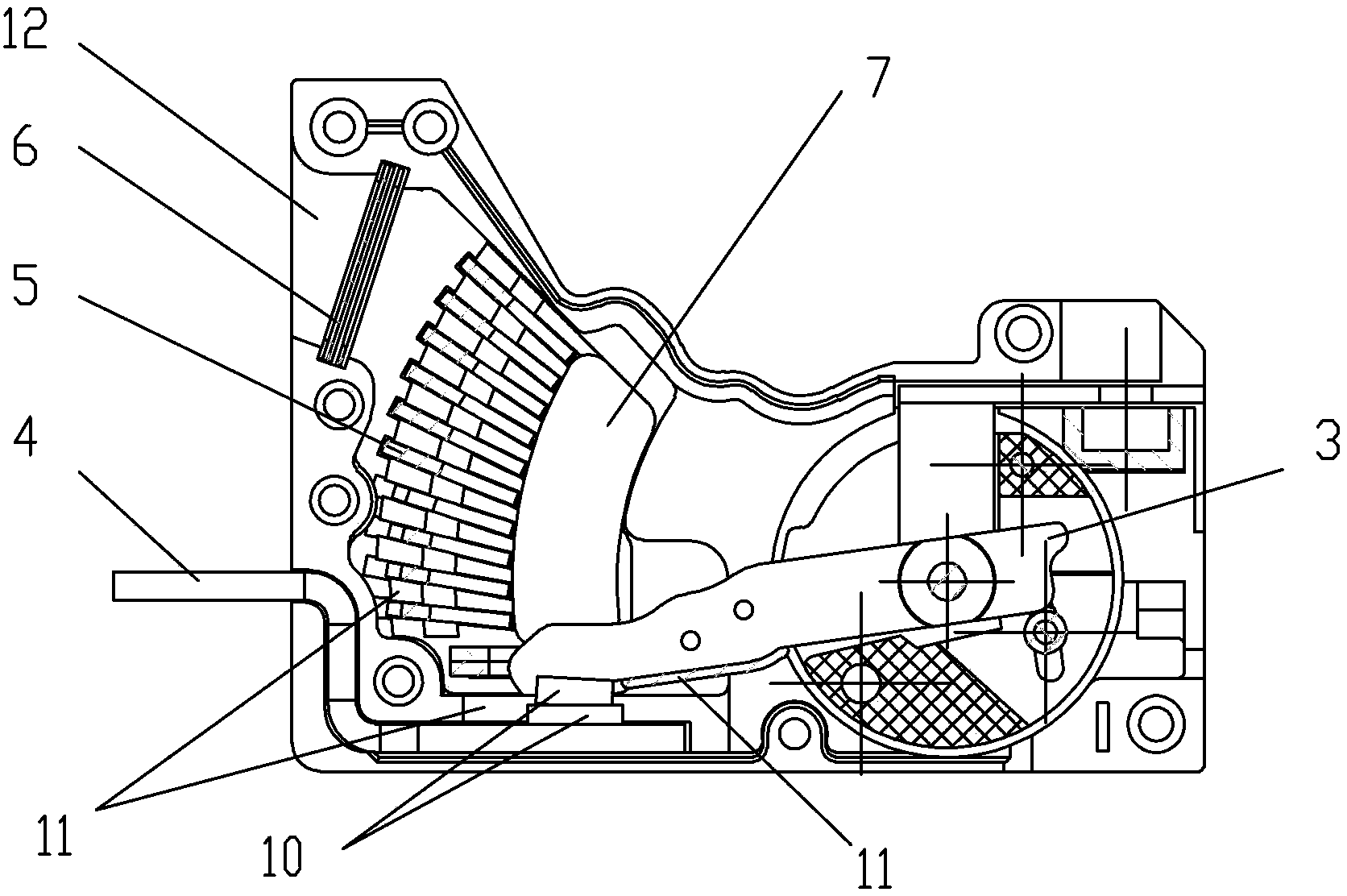

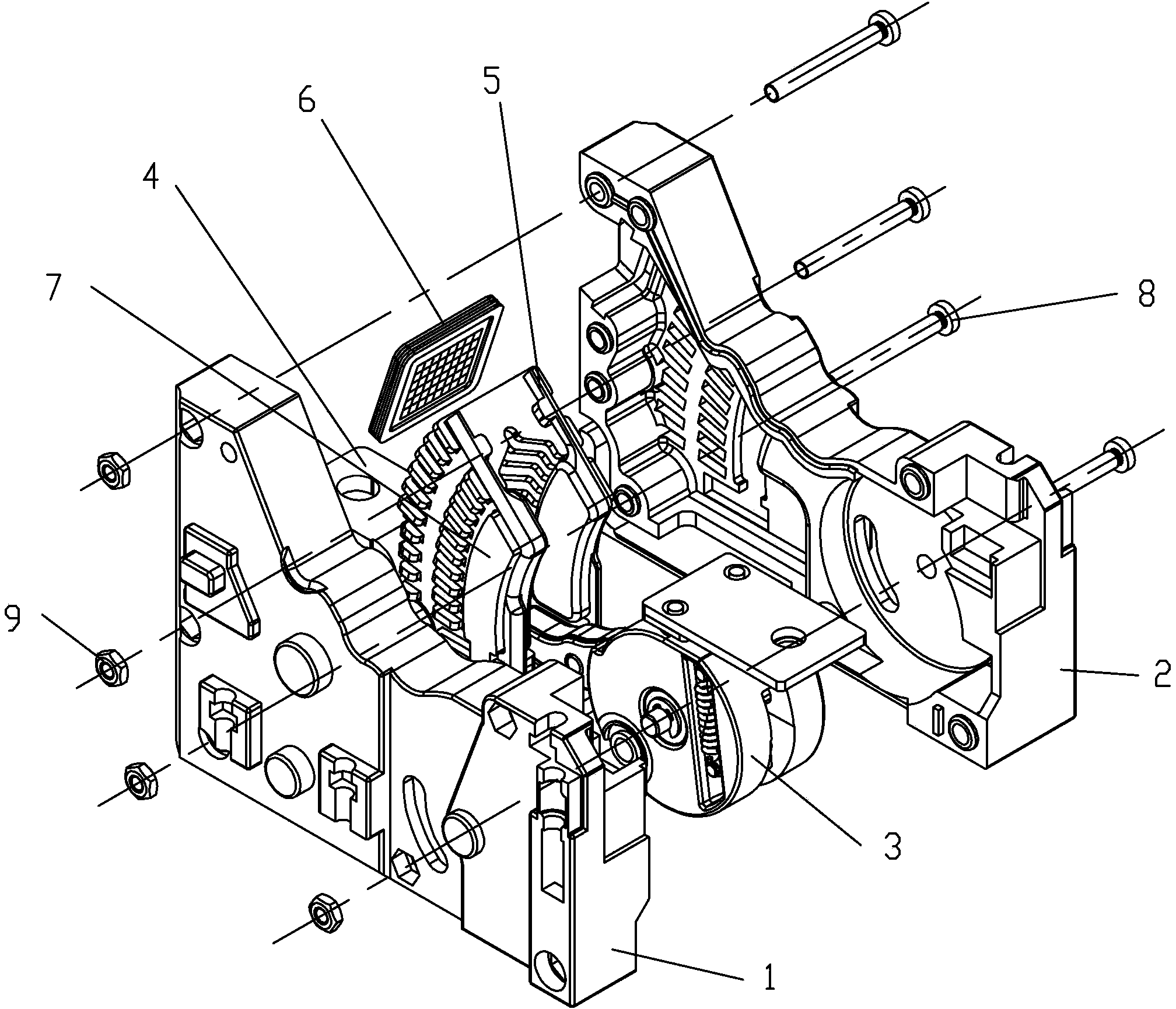

[0012] As shown in the figure, the component box device of the low-voltage molded case circuit breaker of the present invention consists of the left block 1 of the component box, the right block 2 of the component box, the moving contact system 3, the static contact system 4, the arc extinguishing cover system 5, the zero fly Composed of arc device 6, self-excited electromagnet 7, screw 8, and nut 9, the moving contact system 3, static contact system 4, arc extinguishing cover system 5, and zero flashover device 6 are packaged in the left block of the component box 1, component box In the closed space formed by the right block 2, the screws 8 and nuts 9 are fastened and installed. The self-excited electromagnet 7 is installed on the left and right sides of the arc chute system 4. While the arc chute system 4 is packaged, the self-excited electromagnet The installation position of the iron 7 is clamped; the inner end of the static contact system 4 is provided with a silver point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com