Large-scale flat plate milling equipment

A flat, large-scale technology, used in grinding/polishing equipment, metal processing equipment, grinders, etc., can solve the problem of no large-scale plane effective mechanical grinding method, etc., to protect from scratches, easy to operate, and save human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

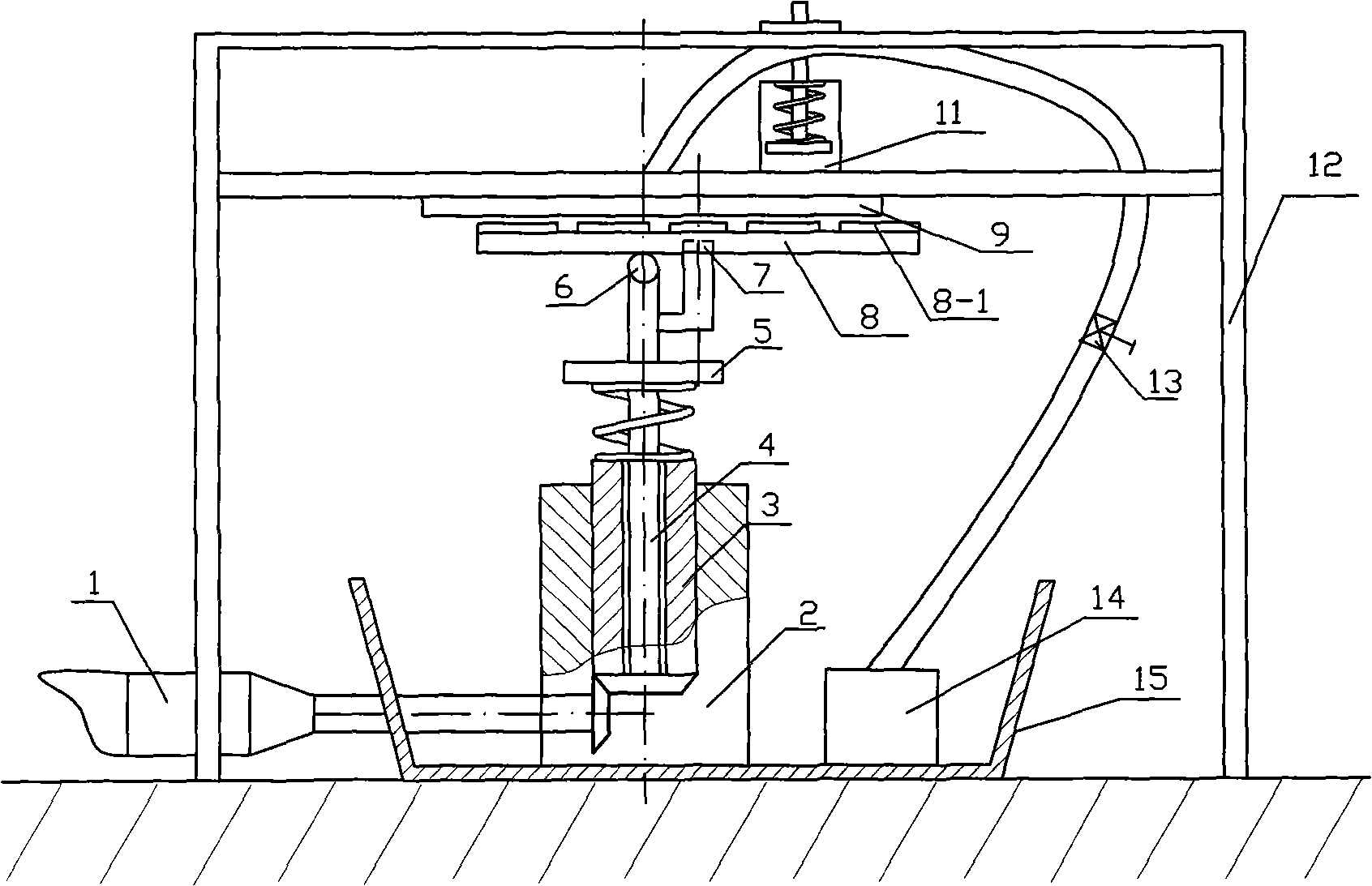

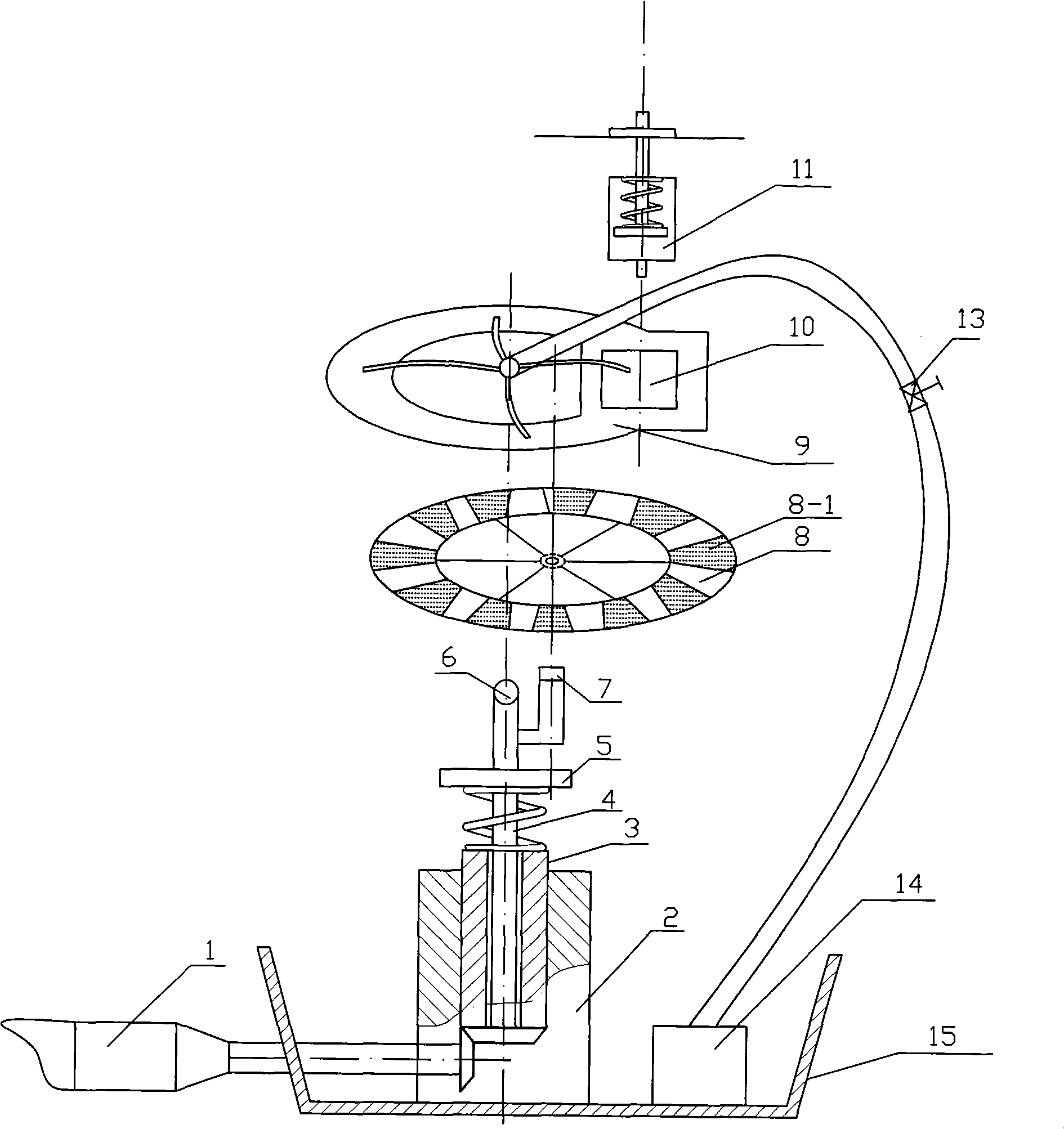

[0020] The large flat plate grinding equipment provided by the invention has a structure such as figure 1 and figure 2 Shown: including driving device 1, grinding mechanism and supporting part. in:

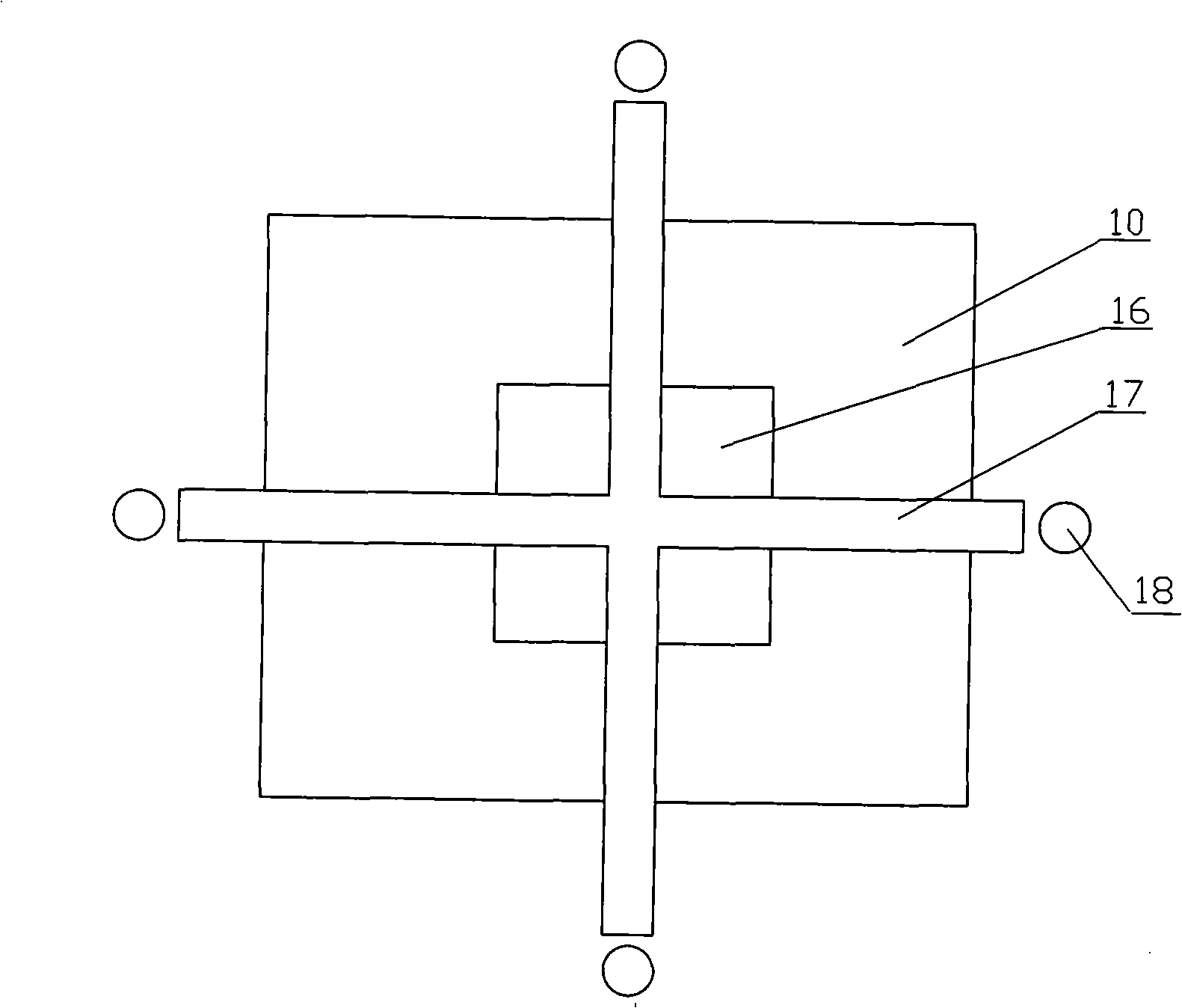

[0021] Grinding mechanism: a grinding rod 4 is provided, and a hole corresponding to the top bead 6 is opened on the top, and the top bead 6 is installed inside; the lower part is square and connected with the inner cavity of the shaft sleeve 3; And the folded support rod, nut 5, spring of following arrangement; The top of folded shaped support rod is equipped with toggle bearing 7, can make toggle bearing 7 drive grinding disc 8 to carry out eccentric swing like this. A grinding disc 8 is provided, and the size of the toggle bearing 7 matches the central groove of the grinding disc. Also be provided with oil pump 14 and the oil pipe that is connected with it, this oil pipe is equipped with switch 13; The output end of this oil pipe is provided with 4 oil distribution pipes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com