Automatic flexible chucking tools

A flexible and fixture technology, applied in the field of fixtures, can solve problems such as high requirements for fixtures, difficulty in automatic grasping, shape and position errors of workpieces, etc., to achieve the effect of increasing contact area, compensating shape errors, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

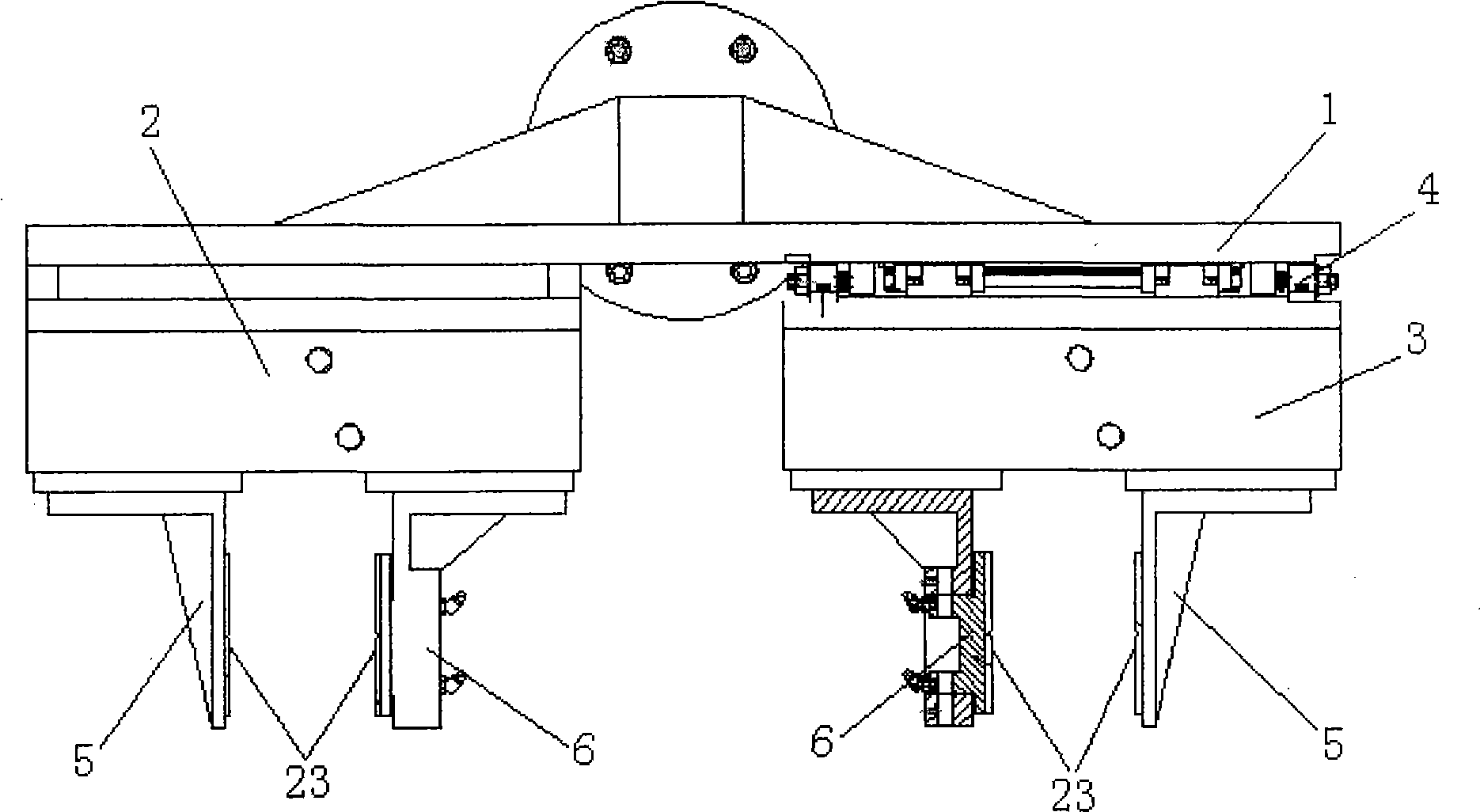

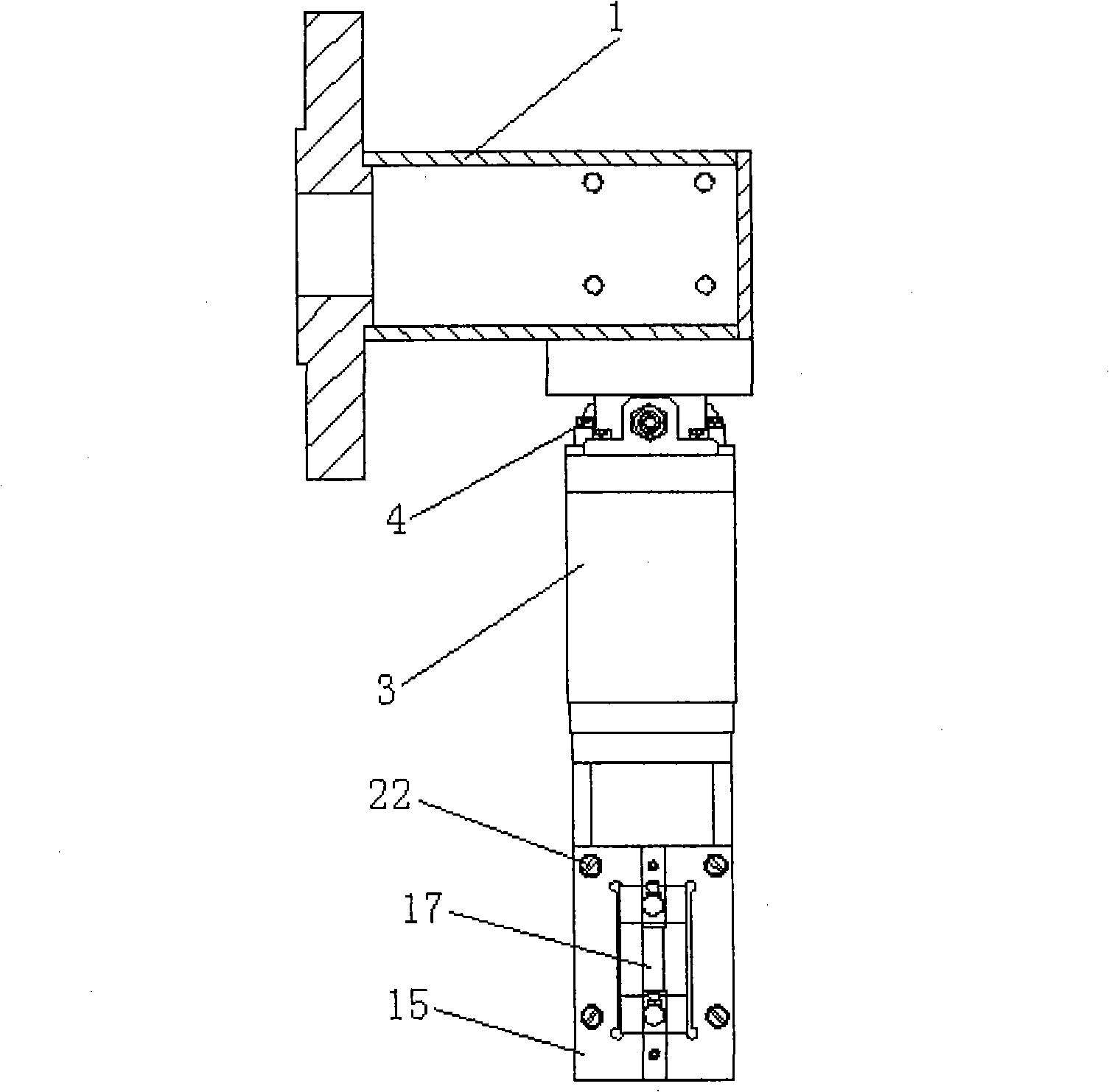

[0016] Such as figure 1 , figure 2 As shown, the present invention includes a mounting bracket 1, two sets of clamping devices 2 and 3 arranged symmetrically, wherein one set of clamping devices 2 is directly fixedly connected to the bottom side of the mounting bracket 1, and the other set of clamping devices 3 passes through a The cover floating mechanism 4 is connected to the other side of the bottom of the mounting bracket 1 . Simultaneously, the bottoms of the two clamping devices 2, 3 are respectively symmetrically provided with a jaw 5 and a floating jaw 6, and the jaw 5 and the floating jaw 6 are driven by an air control device in the prior art to move oppositely or relative to each other.

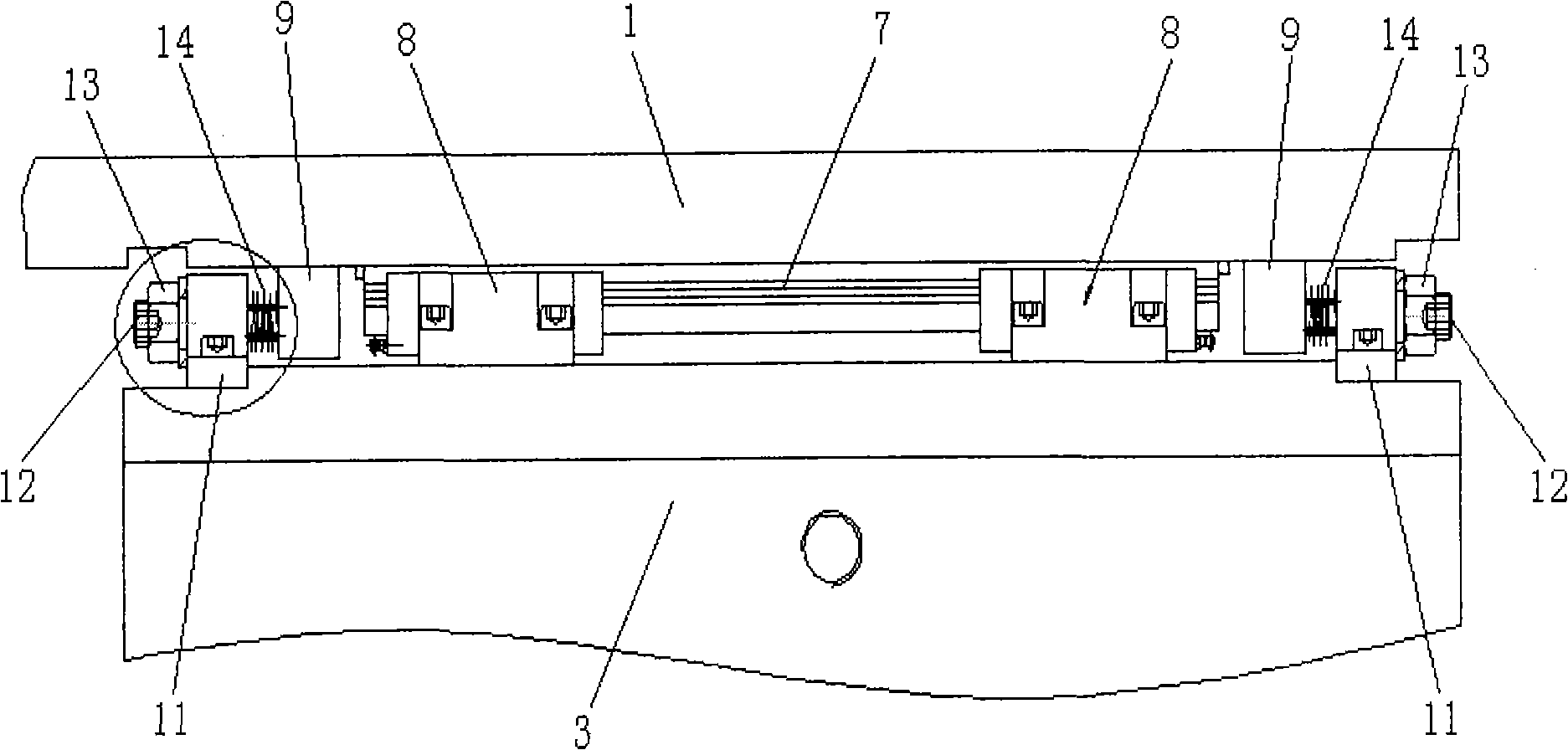

[0017] Such as image 3 , Figure 4 As shown, the floating mechanism 4 includes a guide rail 7 fixedly installed on the bottom of the mounting bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com