Aluminum electrolysis prebake anode roasting 24 hours period production technique

A 24-hour, pre-baked anode technology, applied in the field of roasting and heating process, can solve the problems of not determining the roasting heating curve of the 24-hour flame moving cycle, increasing difficulties, etc., to achieve good economic benefits, increase temperature, and increase the effect of output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

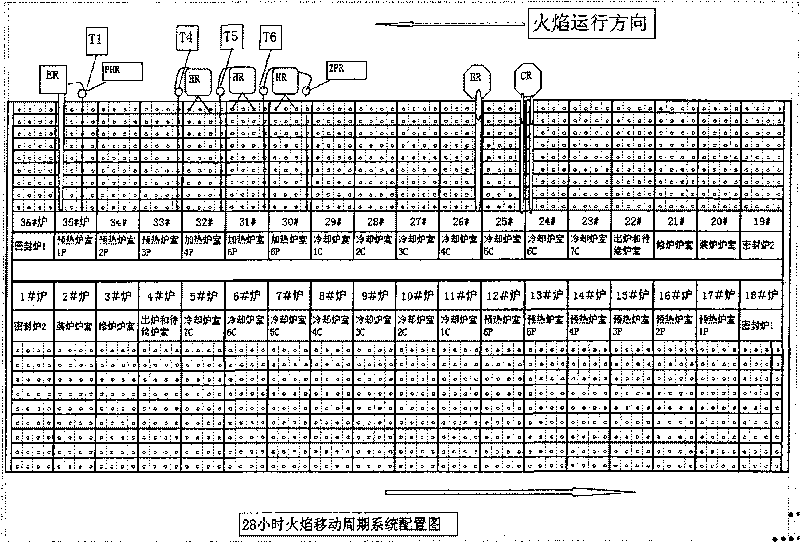

[0047] The roasting and heating process with a flame movement period of 24 hours provided by the present invention is adopted on a system with a flame movement period of 28-36 hours. The roasting and heating process curve is set as follows:

[0048] 24 hours flame movement cycle T1 temperature setting program

[0049]

Serial number

Elapsed time

(h)

Temperature set point

(℃)

Heating rate (℃

/ h)

Upper limit of temperature difference

(℃)

Lower limit of temperature difference

(℃)

1

0

260

30

30

2

2

284

12.00

30

30

3

5

321

12.33

30

30

4

12

408

12.43

30

30

5

18

484

12.67

30

30

6

24

560

12.67

30

30

[0050] 24 hours flame movement cycle T4, T5, T6 temperature setting program

[0051]

Serial number

Elapsed time

(h)

Temperature set point

(℃)

Heating rate

(℃ / h)

Upper limit of temperature difference

(℃)

Lower limit of temperature difference

(℃)

1

0

880

2

5

908

5.6

3

24

1050

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com