Rapid response infrared detector and method for making same

A fast-response, infrared light technology, applied in the field of photodetectors, which can solve problems such as slow response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

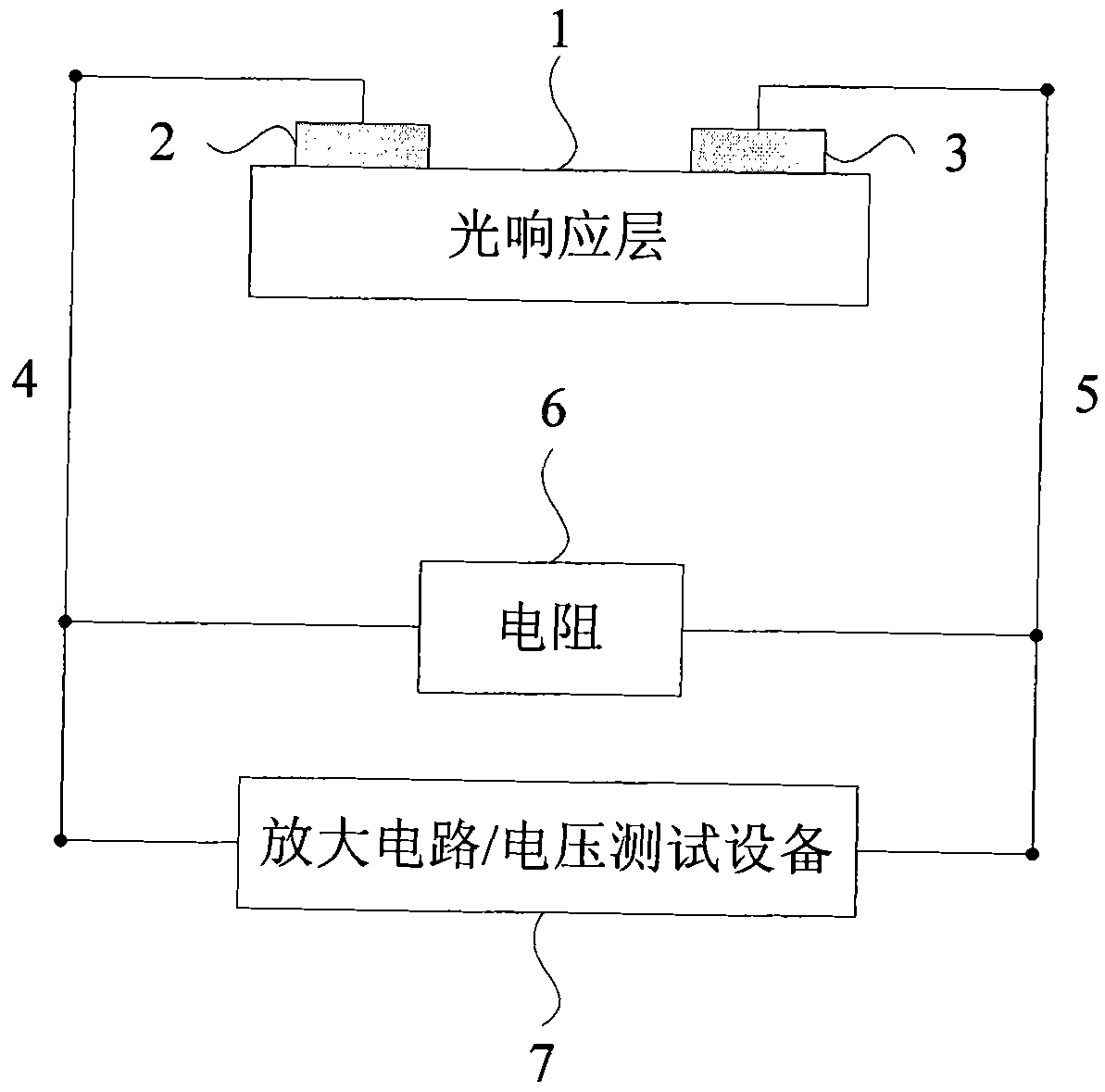

[0026] Please refer to figure 1 , Prepare one based on Al 2 O 3 Single crystal or Al 2 O 3 The preparation method of the film infrared light detector includes the following steps:

[0027] 1. First of all, the pulsed laser film forming process is adopted, and the aluminum alloy is 5mm×10mm×0.5mm. 2 O 3 Single crystal or Al 2 O 3 The film is divided into a silver film with a thickness of 1nm and an area of 5mm×1mm on both sides using a mask method;

[0028] 2. Take the samples made above and follow figure 1 The structure shown is made, the first electrode 2 and the second electrode 3 are vapor-deposited on 1, respectively, the first electrode lead 4 and the second electrode lead 5 are welded on the first electrode 2 and the second electrode 3, and the A resistor 6 of 1 MΩ is connected in parallel between the first electrode lead 4 and the second electrode lead 5, and the output ends of the two electrode leads can be connected to a voltage measuring device 7. This embodiment uses an...

Embodiment 2

[0031] Please refer to figure 1 , Prepare one based on Al 2 O 3 Single crystal or Al 2 O 3 The preparation method of the film infrared light detector includes the following steps:

[0032] 1. First of all, using magnetron sputtering film production process, in 5mm × 10mm × 0.5mm Al 2 O 3 On the single crystal, an aluminum film with an area of 5mm×1mm and a thickness of 10μm is deposited on both sides by a mask method;

[0033] 2. Take the samples made above and follow figure 1 As shown in the structure, the first electrode lead 4 and the second electrode lead 5 are welded to the first electrode 2 and the second electrode 3 respectively, and 1MΩ is connected in parallel between the first electrode lead 4 and the second electrode lead 5 The resistance 6, the output ends of the two electrode leads can be connected to a voltage measuring device 7. This embodiment uses an amplifier circuit or an oscilloscope.

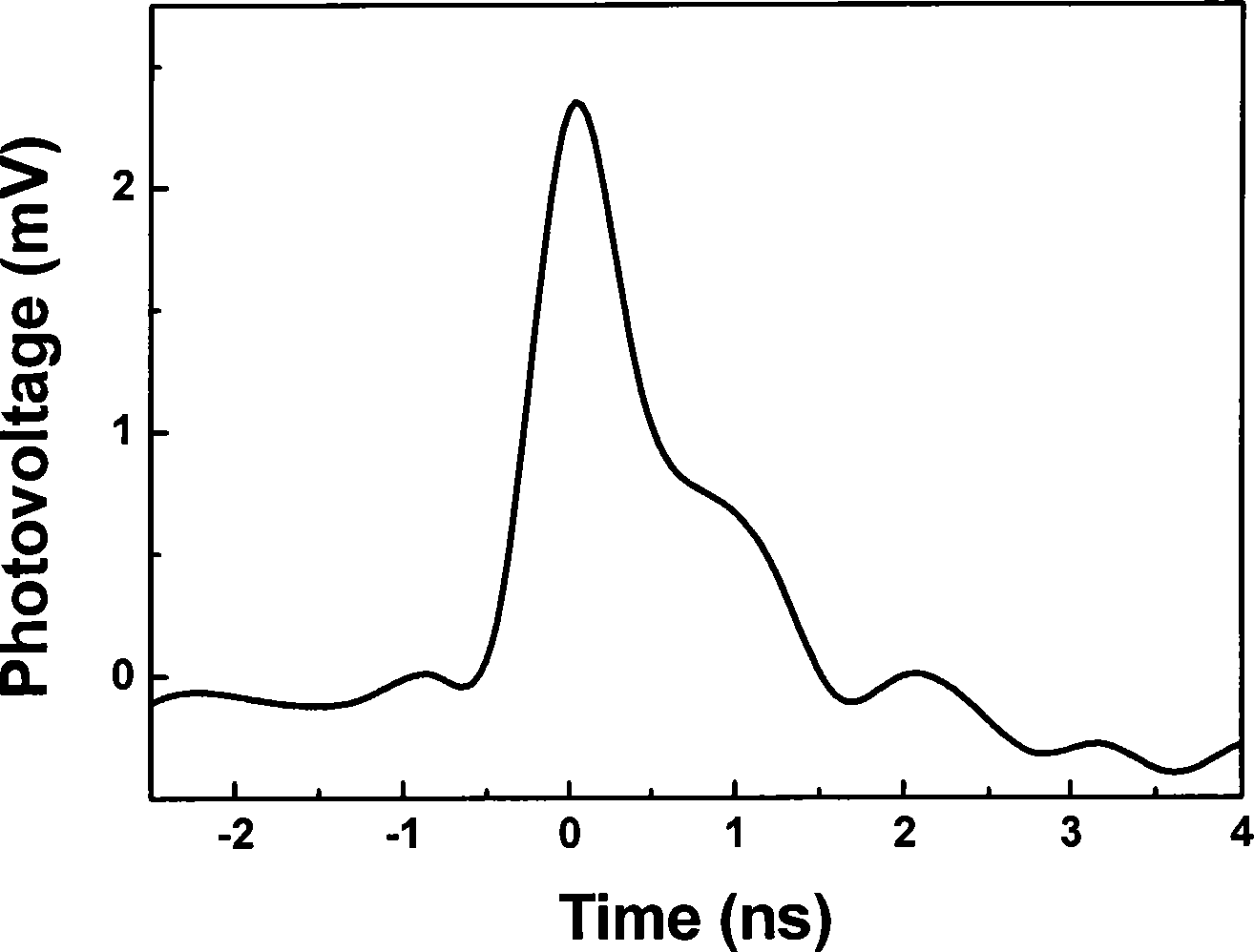

[0034] The prepared detector probe is irradiated by 808nm infrared laser, an...

Embodiment 3

[0036] Please refer to figure 1 , Prepare one based on Al 2 O 3 Single crystal or Al 2 O 3 The preparation method of the film infrared light detector includes the following steps:

[0037] Will Al 2 O 3 Single crystal or Al 2 O 3 The film is made like figure 1 The detector shown outputs a photovoltaic signal under the irradiation of a 980nm infrared laser.

[0038] 1. First of all, using a conventional spot welding machine, in the 5mm × 10mm thickness of 1nm Al 2 O 3 An indium electrode with an area of 1mm2 and a thickness of 1μm is welded on the film;

[0039] 2. Take the samples made above and follow figure 1 The structure shown is made, the first electrode lead 4 and the second electrode lead 5 are welded to the first electrode 2 and the second electrode 3 respectively, and 0.1Ω is connected in parallel between the first electrode lead 4 and the second electrode lead 5 The output ends of the two electrode leads can be connected to the voltage measuring device 7. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com