Electric connector, metal shell and its making method

A technology for metal shells and electrical connectors, applied in the manufacture of contact boxes/bases, protective grounding/shielding devices for connecting parts, etc., can solve problems such as manufacturing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

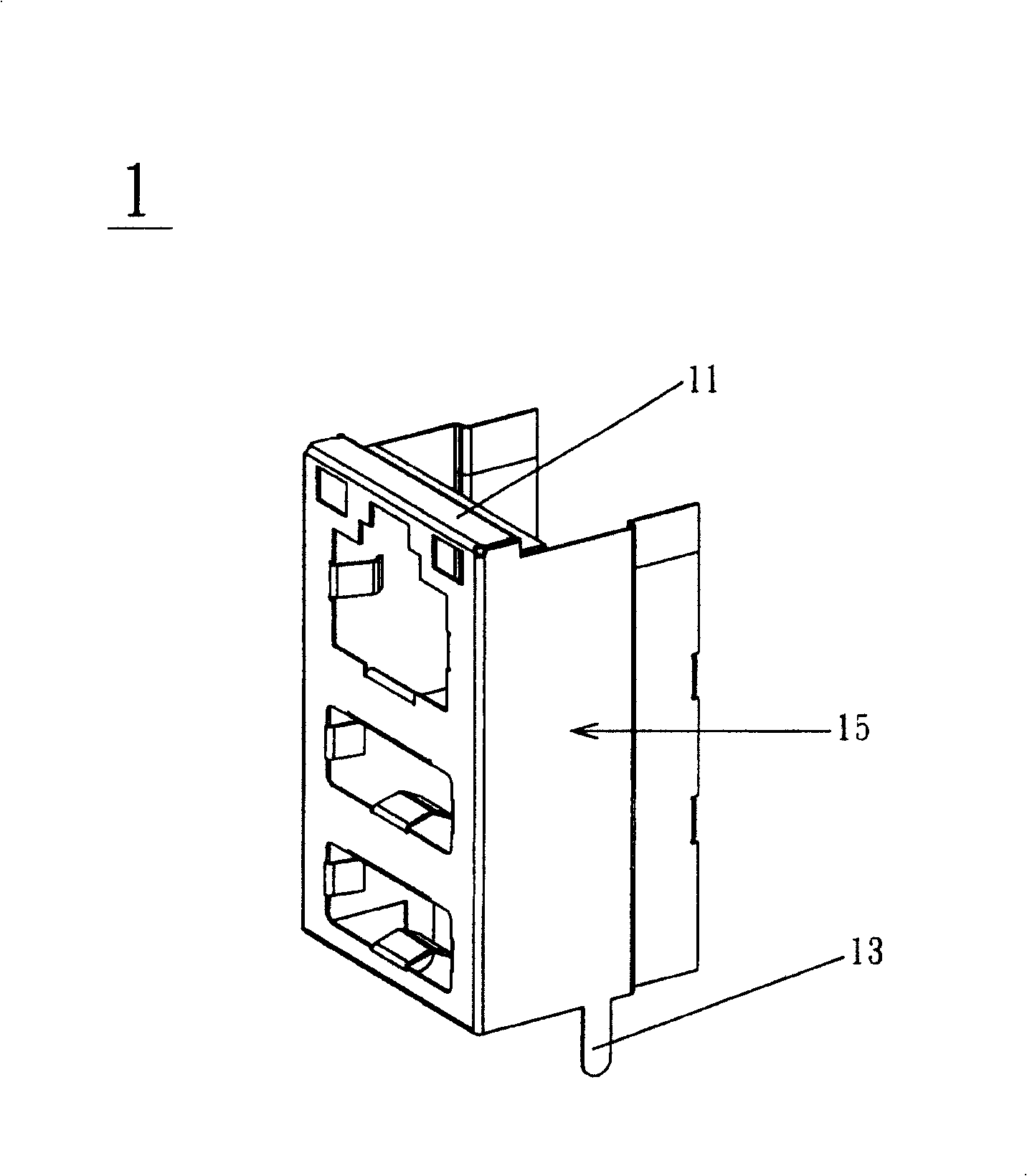

[0041] see figure 2 , figure 2 It is a three-dimensional schematic view of a metal casing according to a preferred embodiment of the present invention. The metal shell 2 includes a body 21 and at least one grounding pin 23. The grounding pin 23 is integrally formed on the body 21, and the grounding pin 23 is formed by punching without waste.

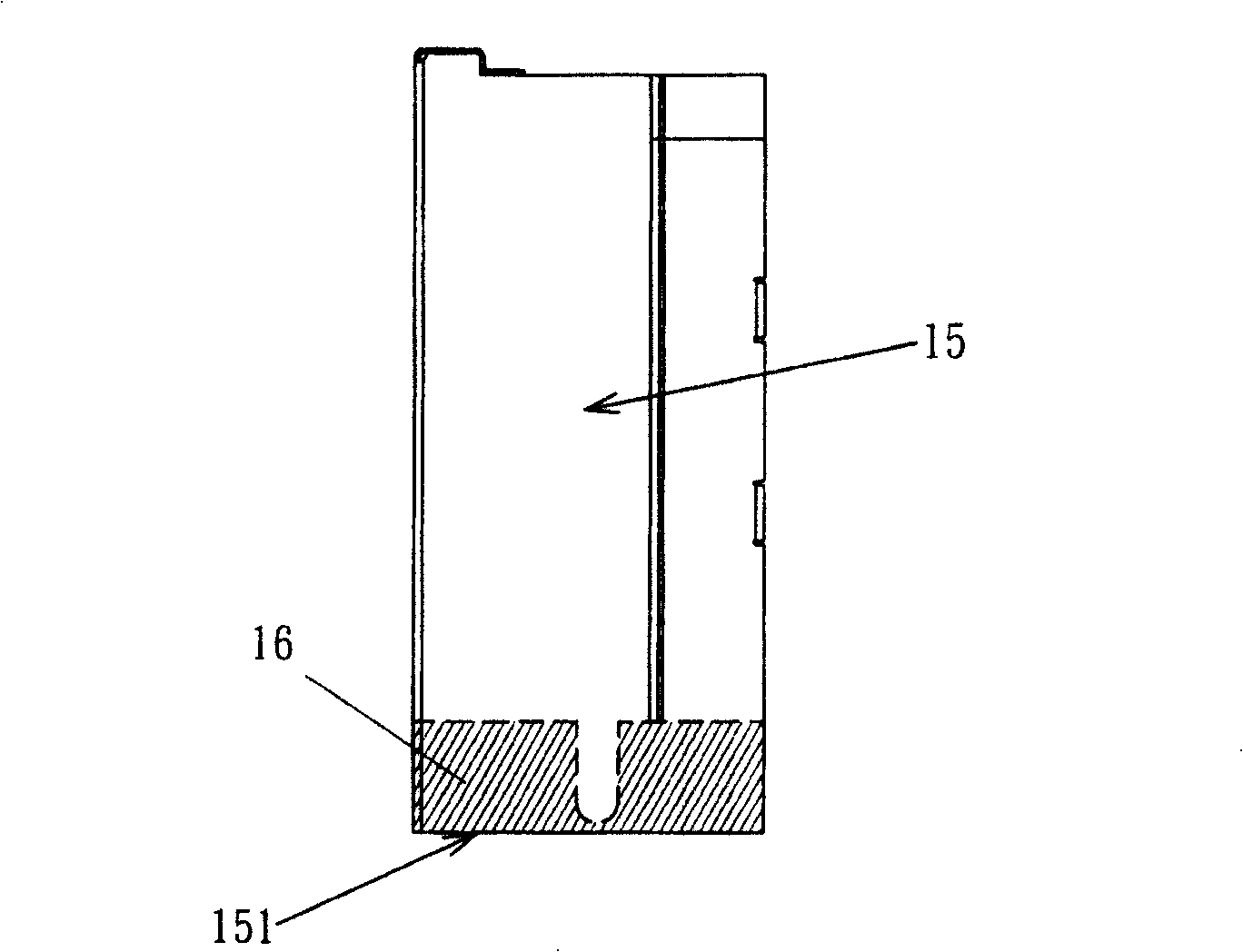

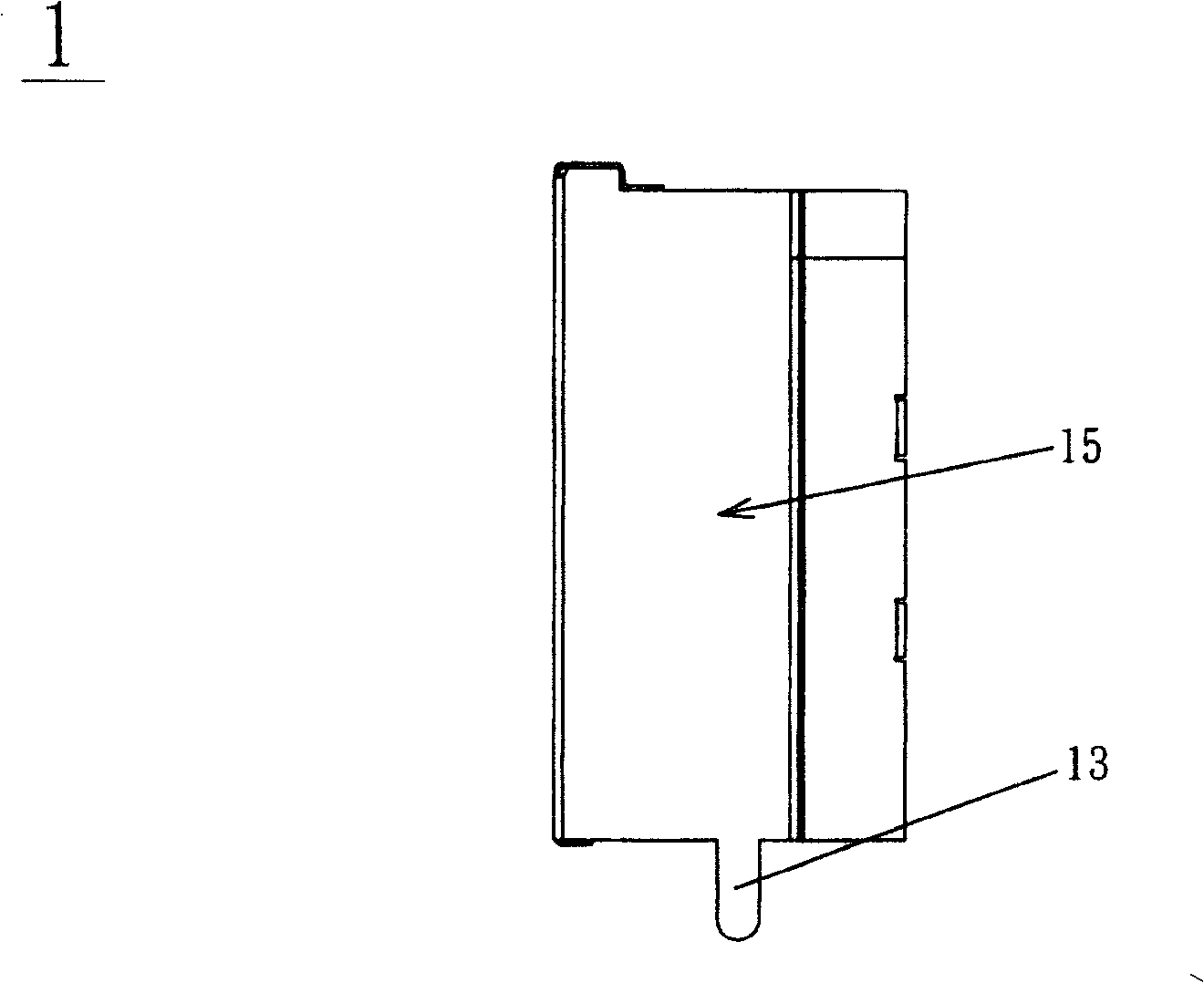

[0042] Please also see Figure 3A and Figure 3B , Figure 3A in accordance with figure 2 Schematic diagram of the side of the metal shell after the strip is punched out, Figure 3B in accordance with Figure 3A The side view of the metal shell after bending the strip part. The following is a detailed description of the manufacturing method of the metal shell 2: first, a body 21 is provided, a certain distance D is selected from the edge 251 of the body, and at least one strip 28 is cut out by punching, and the strip 28 The cutting length L can be varied according to actual needs, but must be greater than a certain distance D,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com