Ventilation device for a fuel container

A technology of exhaust device and fuel tank, which is applied in the direction of power device, layout and packaging combined with fuel supply of internal combustion engine, can solve problems such as interference and energy consumption of fuel pump, and achieves low control cost, simple control and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

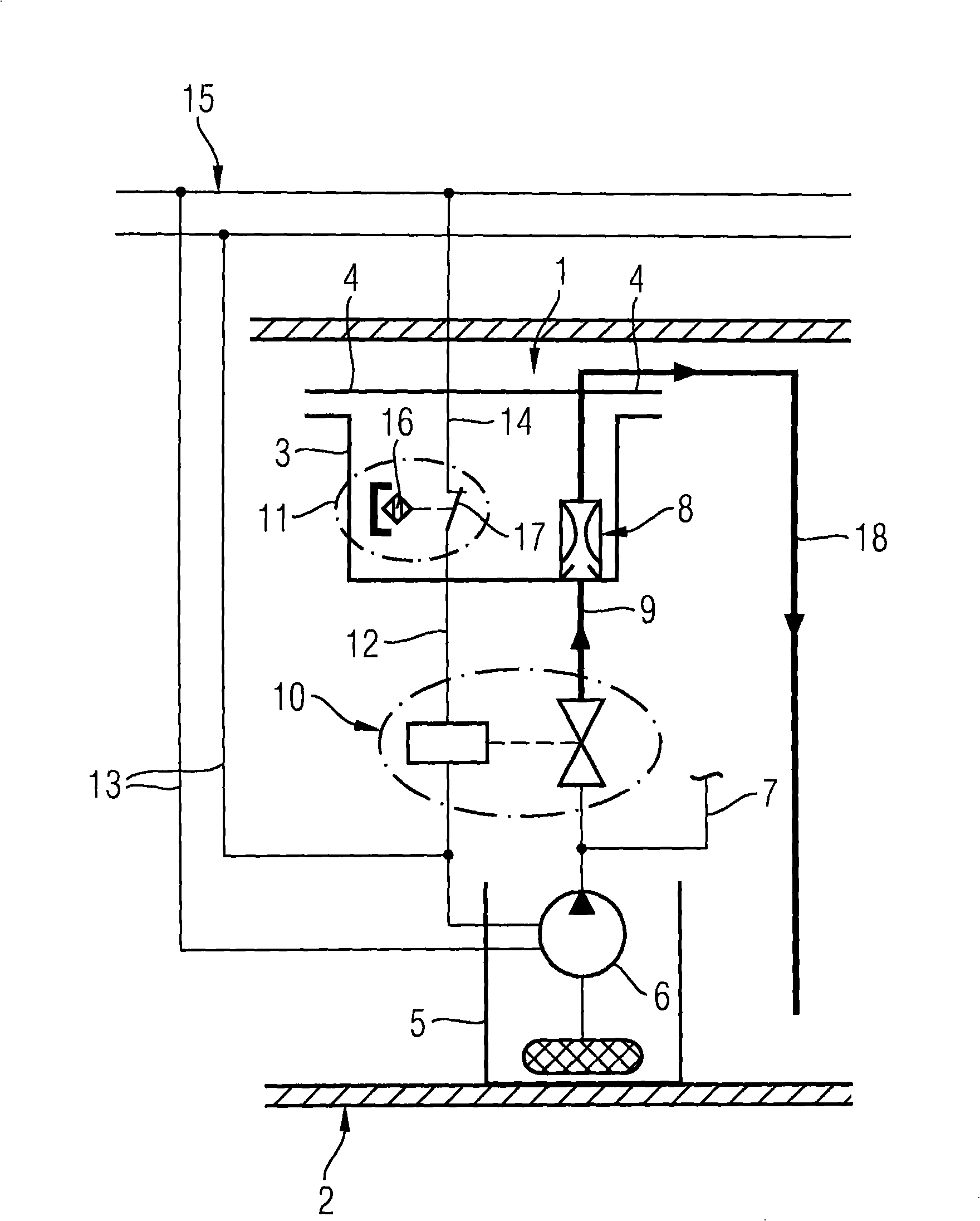

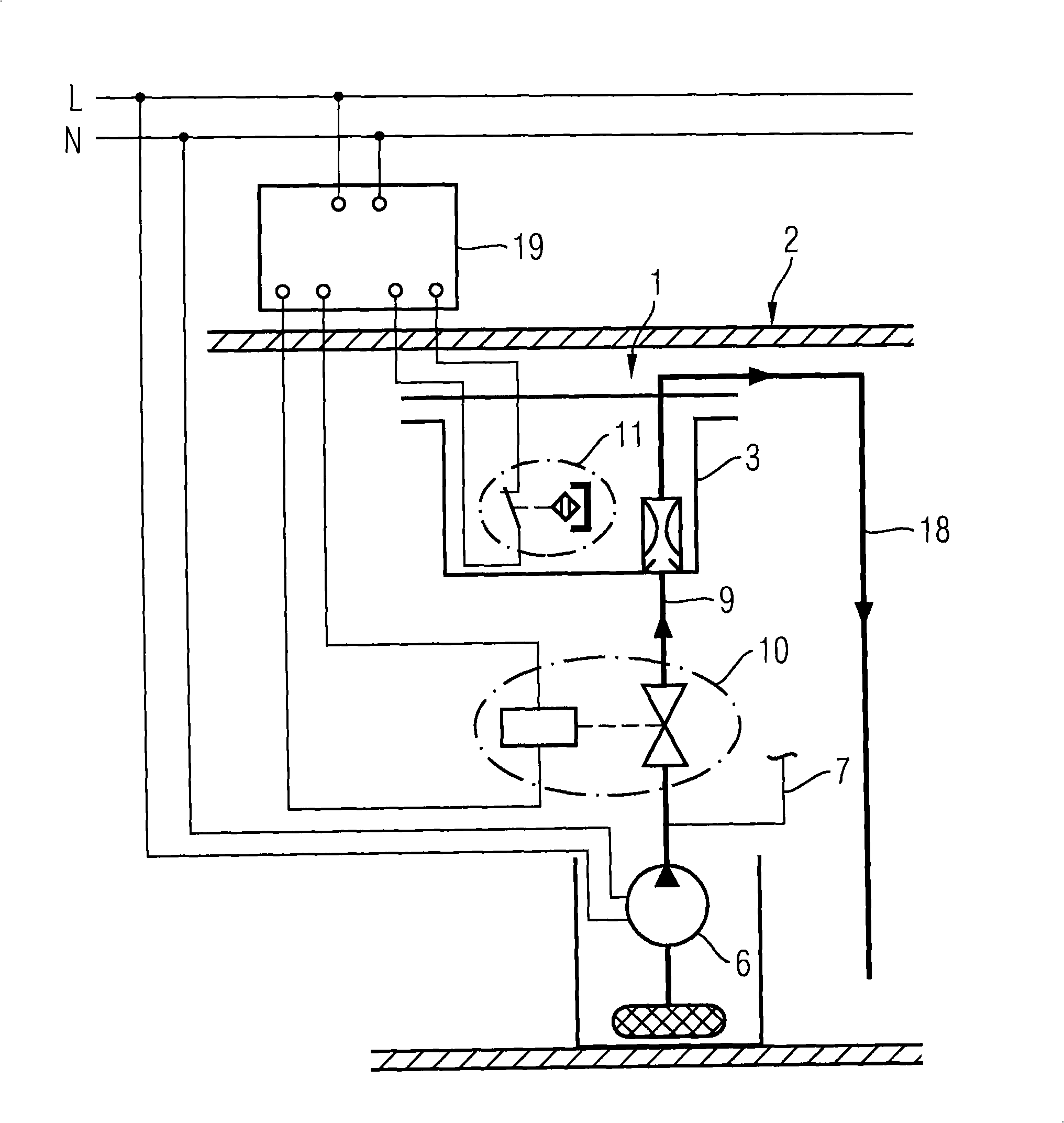

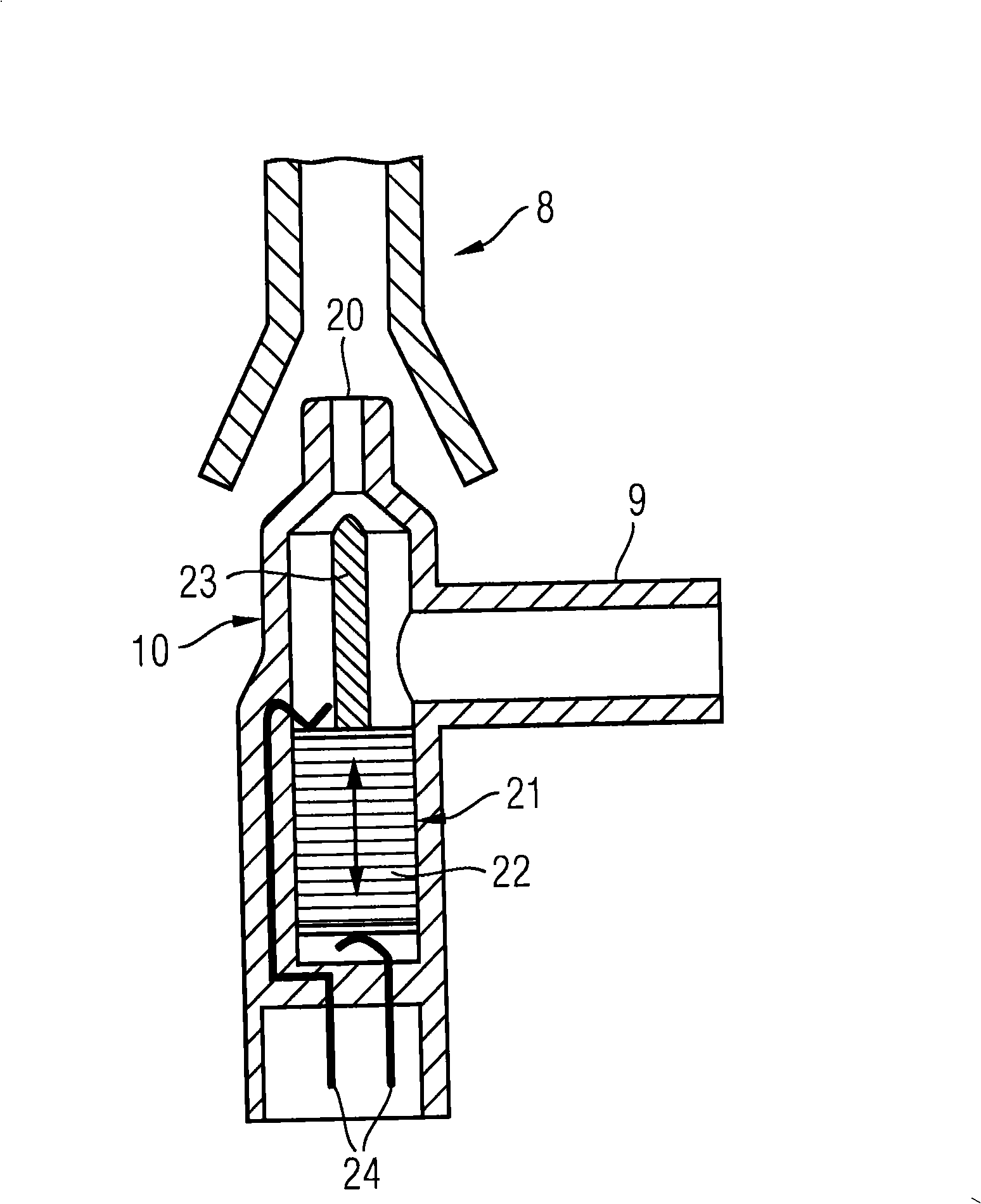

[0023] figure 1 An exhaust device 1 for a fuel tank 2 of a motor vehicle is shown, with a liquid trap 3 arranged in the upper region. The exhaust device 4 leads from the accumulator 3 to the side area of the fuel tank 2. In addition, an anti-swirl box 5 with an electric fuel pump 6 is provided at the bottom of the fuel tank 2. The fuel pump 6 draws fuel from the anti-swirl box 5 and delivers the fuel to the internal combustion engine of a motor vehicle, not shown, through a supply line 7. A suction and injection pump 8 is provided in the liquid collector 3, and the suction and injection pump is connected to the supply pipe 7 of the fuel pump 6 through a delivery pipe 9. An electrically switchable valve 10 is provided in the conveying pipeline 9, and the valve is connected to a liquid level limit switch 11 provided in the liquid collector 3 through an electric wire 12. The liquid level limit switch 11, the electrically switchable valve 10, and the fuel pump 6 are also connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com