Golf club head and its manufacture method

A technology for golf club heads and golf club heads, which is applied to golf balls, golf clubs, rackets, etc., and can solve problems such as poor ball control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

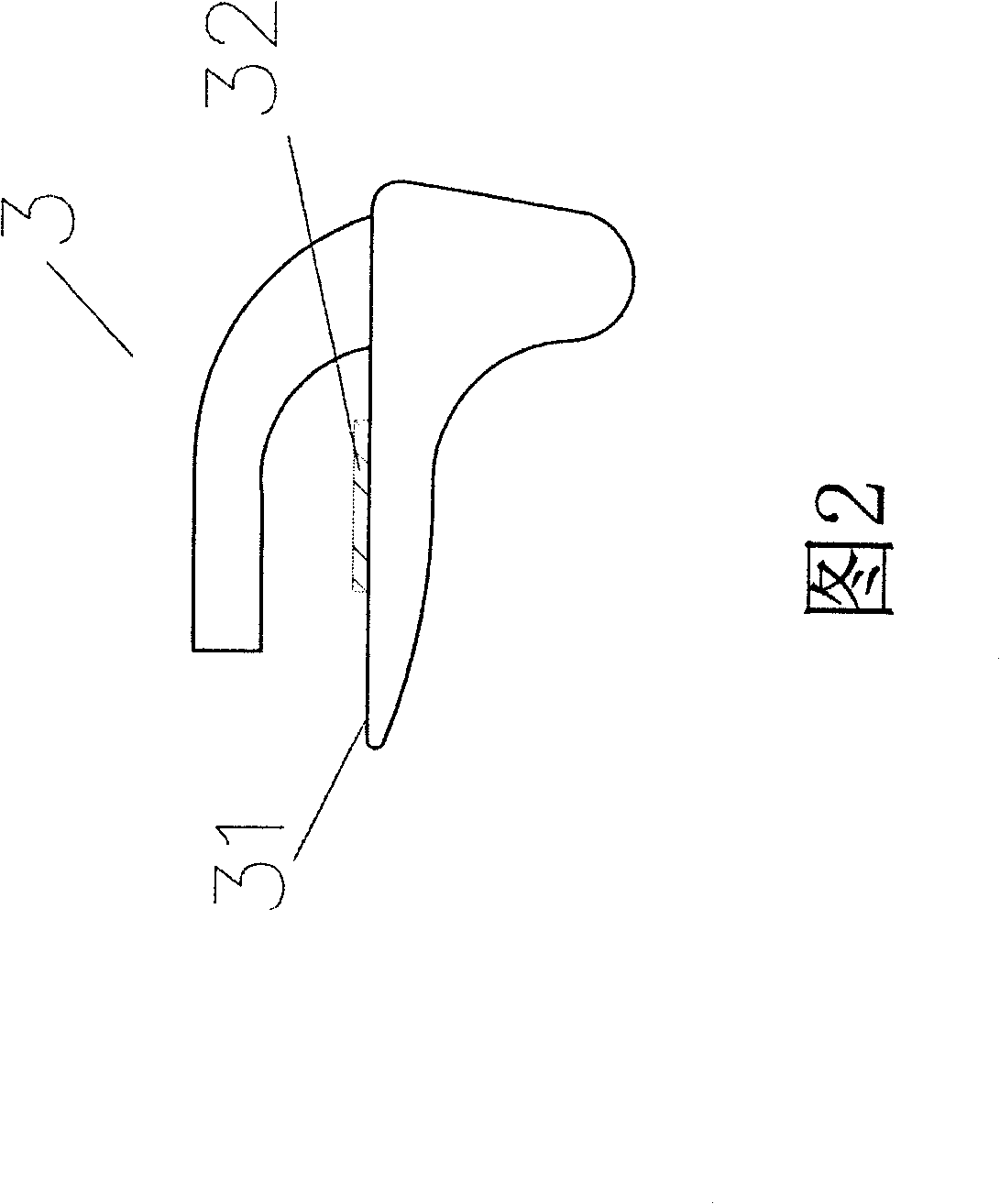

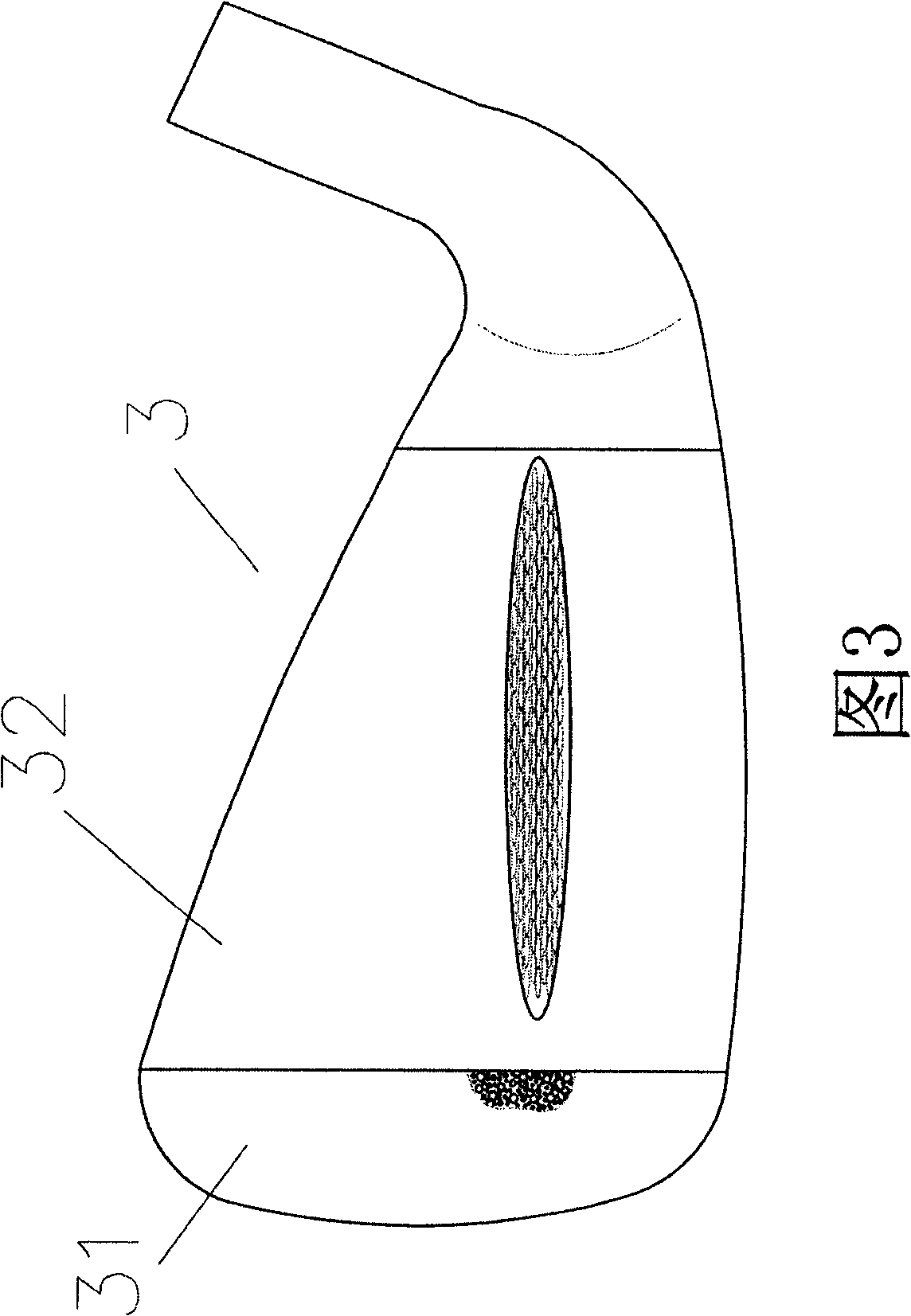

[0013] In order to understand the effect of the club head of the present invention and its manufacturing method more easily, the description is as follows in conjunction with the accompanying drawings.

[0014] In the club head of the present invention, during the manufacturing process, the entire striking area or part of the striking surface is stamped for different times or processed by heat treatment or by means of stamping and heat treatment to make the crystal grains there The configuration is changed to make the tissue structure of the place different, so as to change the hardness of the place, so that the hardness of the place is increased or decreased compared with its peripheral part.

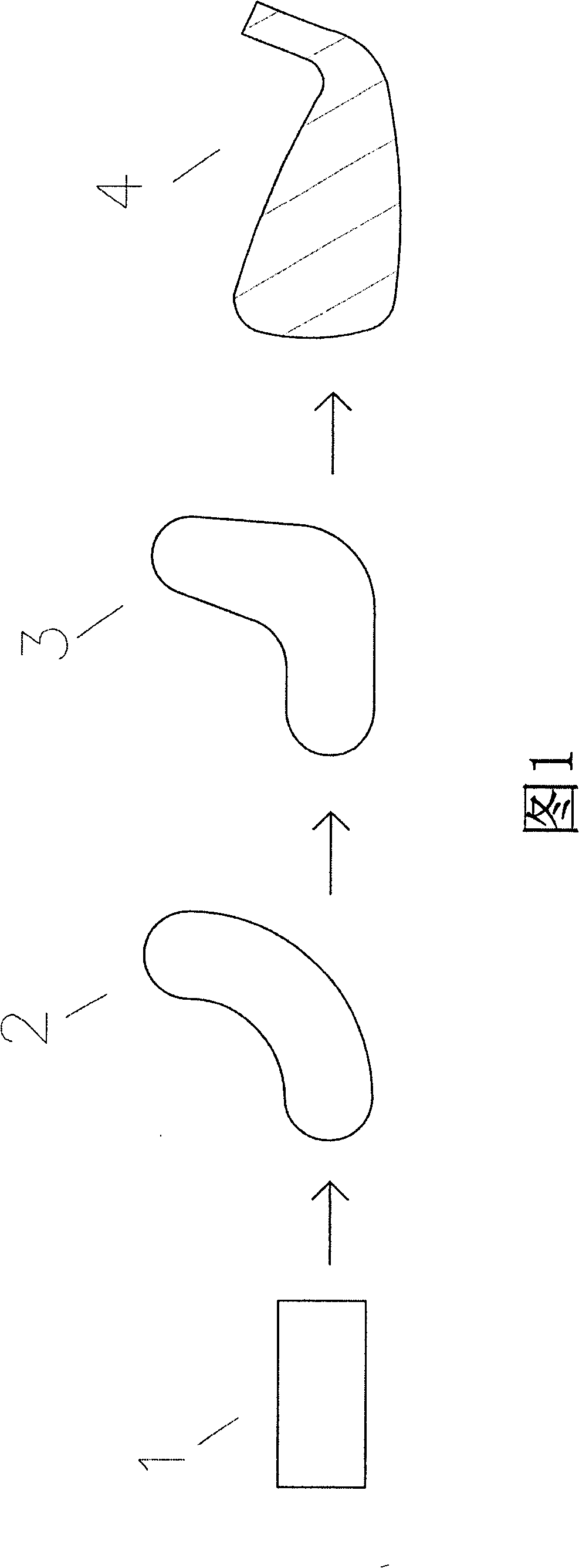

[0015] First please refer to Fig. 1, when the club head of the present invention is formed by stamping method, a round bar 1 is first cut, and then bent and stamped to form a club head embryo block 2, and then carried out 2 to 3 times Rough forging and stamping to form a rod head rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com